Tips and tricks from the HEIDENHAIN Service department

Do you have questions related to our Service department?

Look here for information that will quickly enhance your daily work.

Retrofit your machines with robots anytime: call HEIDENHAIN

There are good reasons to automate your manufacturing process, including staffing shortages, time pressures and the potential benefits of unattended shifts. But is a new machine really worth the investment? For machine tools with a HEIDENHAIN control, a robot retrofit may be an attractive alternative. To ensure smooth communication between your robot and the control, the HEIDENHAIN Service department provides convenient connectivity support.

NC programming | PLC programming | APP programming | Machine optimization | On-site service | CNC controls | Digital Shop Floor software solutions | Motoren und Umrichter | Inspection & testing devices

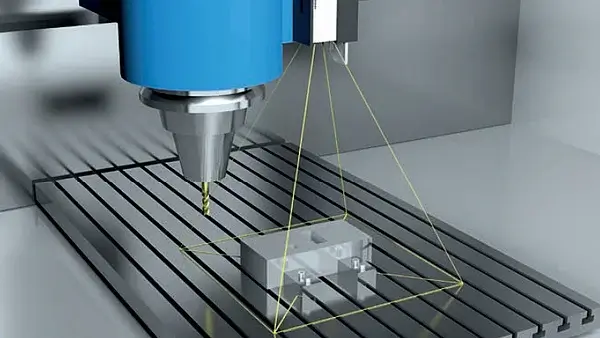

Inspect tools up to six seconds faster with a retrofitted TD 110

Automatically detect broken tools and avoid knock-on damage: the TD 110 tool breakage detector boosts process reliability and inspects each tool up to six seconds faster than conventional laser solutions. Almost as fast as the TD 110 itself is the HEIDENHAIN Service team’s TD 110 remote installation service.

NC programming | PLC programming | APP programming | Machine optimization | On-site service | CNC controls | Digital Shop Floor software solutions | Motoren und Umrichter | Touch probes and vision systems | Inspection & testing devices

Your alternative to on-site servicing: HELPLINE+

We hope you’re already familiar with our free helplines and on-site HEIDENHAIN technician services. To supplement this offering, the HEIDENHAIN Service department is now introducing its new HELPLINE+ remote maintenance services that save you time and money with greater flexibility.

NC programming | PLC programming | APP programming | Machine optimization | On-site service | Digital Twin | CNC controls | Digital Shop Floor software solutions | Motoren und Umrichter | Signal converters | Touch probes and vision systems | Inspection & testing devices

NC programming | PLC programming | Machine optimization | On-site service | CNC controls | Digital Shop Floor software solutions | Motoren und Umrichter | Touch probes and vision systems | Inspection & testing devices | Length gauges | Digital readouts | Linear encoders | Angle encoders | Rotary encoders

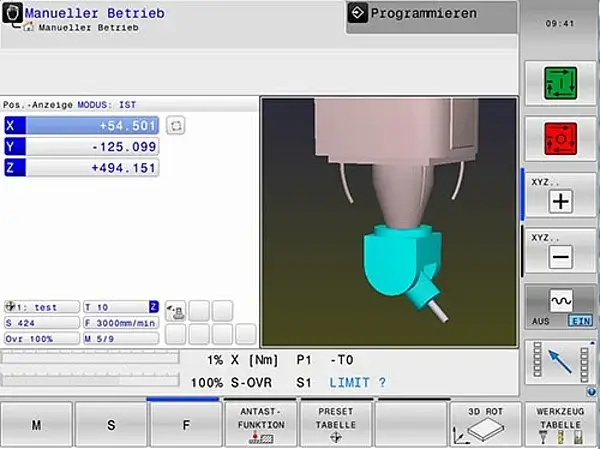

New sample cycles for TNC controls

HEIDENHAIN controls come with a large number of canned cycles for a wide variety of machining tasks. Even so, they cannot cover every possible scenario. That’s why the HEIDENHAIN Service team offers sample cycles that help you individually adapt and expand your control’s range of cycles, including highly specialized ones.

NC programming | PLC programming | Machine optimization | APP programming | Tips and tricks | Digital Shop Floor software solutions | CNC controls

Tips and tricks | Repairs & replacement parts | Replacement devices | Warranty | CNC controls | Touch probes and vision systems | Linear encoders | Angle encoders | Rotary encoders

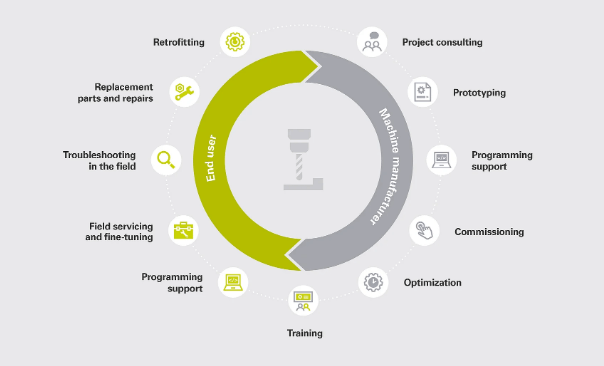

We’re here for you!

Despite the current restrictions on travel, visits, and interpersonal contact, your daily business doesn’t stop, nor does the HEIDENHAIN Service department. This includes all aspects of servicing and maintenance work. We’re currently focusing more on our online offerings but can also visit your site as permitted by the current regulations.

On-site service |

Workspace camera: keep your work in view

A clear view of the work envelope is important and even necessary for many machining operations. Displaying live video on your control or extra monitor requires connectivity with the IP camera system. The HEIDENHAIN Service department can also support you in implementing a workspace camera.

PLC programming | Workspace camera

Did you know?

The HEIDENHAIN Service department offers more than repairs, replacement parts and phone support. We can create a digital twin. We can integrate remote tool data management into your machine with its HEIDENHAIN control. Our servicing experts even provide training courses that give you the knowledge to fix machine malfunctions on your own.

On-site service | PLC programming | NC programming | APP programming | Repairs & replacement parts | Replacement devices | Machine optimization | Warranty | Digital Twin | DaKKs calibration | Digital Shop Floor software solutions | CNC controls

Automate with the PNC 610

At the heart of the HEIDENHAIN Automation Solution is the PNC 610 control, which lets you connect external units such as tool, pallet, and workpiece changers to a higher-level control system. The benefits for implementation are vast in conjunction with the PNC basic program. Users enjoy an intuitive interface for machine-tool automation control.

PLC programming | Digital Shop Floor software solutions | CNC controls

Answers to your questions

Have you already discovered the Service & Support page on our HEIDENHAIN website? It’s full of resources about technical support and HEIDENHAIN services, including a software and document download center, a video media library or online tips and frequently asked questions may have just the information you need to troubleshoot the problem.

On-site service | PLC programming | NC programming | APP programming | Repairs & replacement parts | Replacement devices | Machine optimization | Warranty | Digital Twin | DaKKs calibration | Tips and tricks |

PLC programming |

NC programming | Digital Shop Floor software solutions

PLC programming | Digital Shop Floor software solutions

Seamless replacement: a suitable successor model is always available

Proven products naturally have their advantages: they are fully matured, their properties are well known, and there is a certain routine when mounting. However, just as naturally, the progress of technology brings new products to the market at some point. HEIDENHAIN places special emphasis on the transition from the proven product to the innovative successor model being a smoothly flowing action and not an abrupt break.

Repairs & replacement parts | Linear encoders

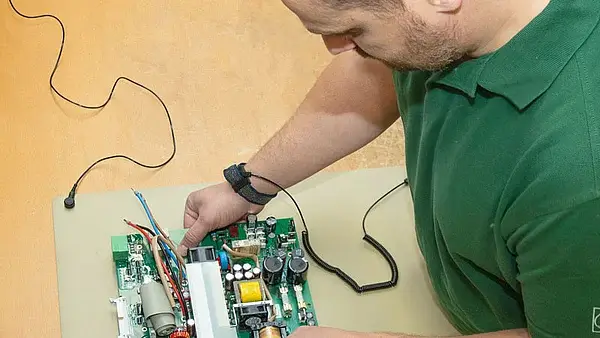

ESD protection for returned units: how to avoid damages

A unit is defective and you return it to the HEIDENHAIN Service department. But please ensure that units returned to us for repairs are given the ESD protection that they need while on the way. In this issue of the Service News we’d like to give you a few tips about the correct handling and packaging of electronic components and units.

Repairs & replacement parts |

PLC programming |

Angle Head Setup: We Can Help

Time and again, machining tasks come up that can’t be accomplished using a conventional machine configuration. This includes the machining of internal features, for example. In such cases, an angle head can help, but using one requires making a number of modifications to the machine, the control, and the NC program. The service technicians of the HEIDENHAIN Customer Service Department can provide assistance.

NC programming |

Cleaning and Repairing of Linear Encoders

The faultless functioning of a linear encoder is decisive for the accuracy of the machine or plant. But the function is affected by countless influences of the daily environment of the shop floor: dust, grease, oil, water and dirt are everywhere and anytime and accumulate on the linear scale or scale tape and scanning head. It is advantageous if there is a strong partner to assist you with a fast repair!

Repairs & replacement parts |

HEIDENHAIN Touch Probes – Fast Replacement in the Event of Collisions

On machine tools, especially on milling machines and machining centers, HEIDENHAIN touch probes help.

When the workpieces are probed, it is possible that collisions occur and the touch probe is damaged. In this case HEIDENHAIN is ready to provide several solutions.

Repairs & replacement parts |

Motor repairs at HEIDENHAIN

HEIDENHAIN Corporation is collaborating with the HEIDENHAIN Service department in Traunreut, Germany for Motor repairs. We founded a new inspection and repair station for motors. It is dedicated to the repair of all asynchronous and synchronous motors of the QAN and QSY series in Traunreut. Thanks to the new inspection and repair station, we have reduced repair times to three to four weeks. We offer a rush repair service with a turnaround of just a few days.

Repairs & replacement parts |

Your selected filter did not return any results.

Reset filter selectionTopics

Product areas