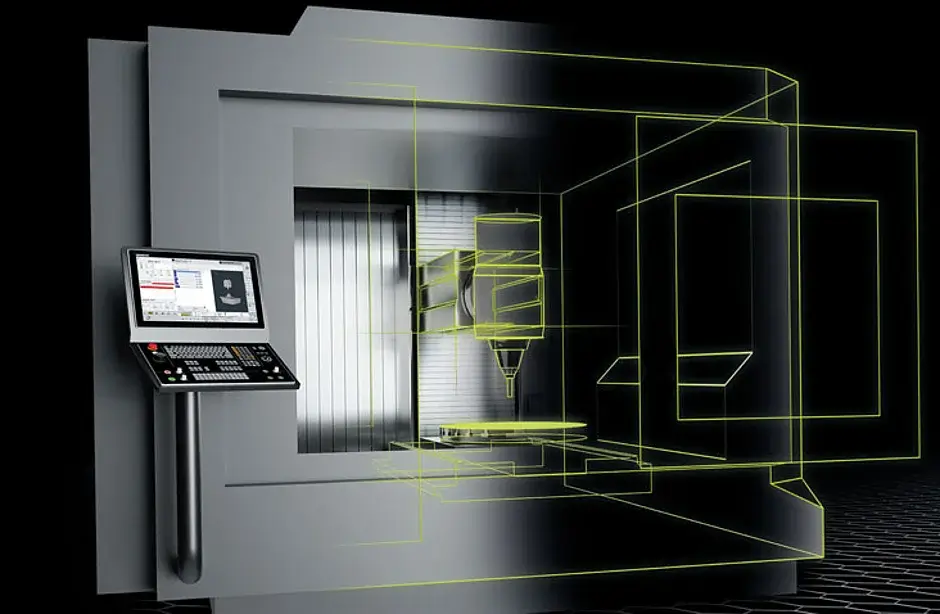

The Digital Twin

A HEIDENHAIN programming station is an exact copy of a control. It can also become a nearly perfect model of the machine: with its Digital Twin, the HEIDENHAIN Service department brings the shop floor to the front office, giving you the peace of mind that programs created with the programming station or CAM software will run properly on the machine.

Realistic simulation for reliable production processes

In the office, the Digital Twin lets you leverage the actual kinematics, parameters, and functions of your machine during part design, program creation, and simulation:

- Check and optimize traversing paths

- Prevent program interruptions

- Avoid collisions

- Make full use of the machine’s work envelope

- Test five-axis movements

- Inspect and optimize the clamping position

On the shop floor, you benefit from reduced setup and simulation times, less program debugging, greater process reliability, and higher productivity.

Beyond helping you create a verified NC program, the Digital Twin also supports you with quoting, job planning, and expert-level TNC training:

- Determine the exact machining times

- Calculate costs and completion dates

- Provide realistic training in NC programming

The easy path to a Digital Twin

Identifying your exact requirements

You simply contact the NC Support & PLC Programming Support helpline: TNCService@heidenhain.com

Preparing a cost estimate and quote

We make a rough cost estimate based on your machine data and prepare an individualized quote.

Placing an order

You review our quote and place an order directly through the NC Support & PLC Programming Support helpline.

Creating a Digital Twin

We adapt the programming station and send you a backup file of the data.

Importing the backup file

You import the backup file into all equivalent programming stations at your company.