Search

Search result for:

Motion control design: The top 5 challenges (and opportunities)

From lowering the cost of advanced technologies to improving functional safety in automated environments, here are the top five challenges and opportunities in today’s motion control design industry.

Tattoo machine developer “ups his game” with new CNC

Tattoo artist and rotary tattoo machinist Dan Kubin “upped his game” with the acquisition of a Webb milling machine equipped with an ACU-RITE MILLPWRG2 control.

Rejuvenating a massive vintage machine tool to greatness

Major Tool & Machine (MTM) in Indianapolis trusted HEIDENAHIN when updating their 20-year-old SCHIESS FZG6 (DSI) gantry milling machine. The rebuild included complete retrofitting of the electrical system, new CNC control/drive systems, and new position feedback with HEIDENHAIN absolute linear scales.

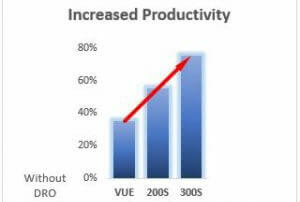

Increase productivity and ROI with ACU-RITE DROs

ACU-RITE digital readouts (DROs) provide increased productivity and a positive return on investment (ROI). They increase accuracy and part tolerances during daily machining projects.

A manufacturing success story

Updated on Sep. 4th, 2019 Manufacturing specialty parts to spec as well as supporting youth-based manufacturing programs has kept Marten ...

ACU-RITE’s new performance-driven digital readout line

HEIDENHAIN's ACU-RITE brand introduces its new line of digital readouts (DRO) for the machine tool marketplace, with exciting new software features and robust hardware that is making a difference for milling, turning, grinding and boring applications — the most complete line in the industry.

Introducing new AMO multi-section linear encoder

HEIDENHAIN is pleased to announce the addition of an exciting new product — the AMO LMF 9310 multi-section linear encoder — specifically designed for long length applications (over 10’) on manually operated machines and is compatible with ACU-RITE brand digital readouts.

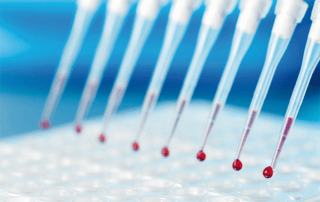

Unique microfluidics manufacturing process enables jaw-dropping biomedical feats

Microfluidics, or lab-on-a-chip technology, is a powerful tool that sits at the intersection of biotechnology, automation and functional integration.

TNC and virtual machining with OPEN MIND

Meeting the needs of the evolving Industry 4.0 manufacturing initiative, OPEN MIND Technologies has recently partnered with HEIDENHAIN TNC controls to provide exclusive first use of their new NC code-based simulation solution hyperMILL® VIRTUAL Machining.

Condition monitoring systems and the importance of the encoder

Whether you are operating a mine, a mill or a power plant, the goal is to generate expected yields and associated revenue. These factories or plants operate continuously to meet their targets. Downtime that is experienced from unplanned failures accounts for lost productivity, and overall costs rise as the difficulty of repair, access, and planning for support equipment contribute to the issues.