May 20, 2020

What are torque motors and why do they work so well?

- Torque motors are a type of direct drive brushless permanent-magnet synchronous motors that are being used increasingly in high-precision applications.

- Benefits of torque motors include minimal mechanical wear, reduced maintenance and system cost, and improved dynamic performance.

- When choosing a torque motor, factors to consider include motor sizing, detent effects, motor constants and thermal considerations.

- Applications range from machine tool to aerospace, as well as semiconductors, factory automation, robotics and machine tooling.

This post was reviewed by Brian Zlotorzycki, North American Application Engineer at ETEL Torque Motors. Updated on December 2, 2022.

Today, direct-drive technology is recognized as a leading solution for the requirements of high productivity, improved accuracy and increased dynamics of modern machinery. They are rigid, more compact, provide high dynamic performance, reduce cost of ownership, simplify the design of the machine and reduce wear and maintenance.

What is a torque motor?

Torque motors are a special class of brushless permanent-magnet synchronous motors. Since the payload is directly connected to the rotor without the use of transmission elements, torque motors are classified as direct drives.

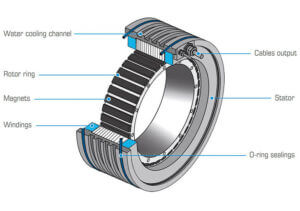

Depending on your perspective, a torque motor is either a rolled-up linear motor or a classic servo drive with a large number of poles. It is the large number of poles that enables conventional torque motors to attain high torque at moderate speeds. Another attractive feature is their compact design, which includes a narrow lamination stack and a large hollow shaft or bore.

As with linear motors, torque motors are a type of “frameless” motor. This means that the motor does not include a housing, bearings or feedback device. These components can be selected by the machine builder and optimized according to the required performance or purchased as part of an assembly.

Torque motors produce high torque at moderate speeds and even when stationary. Contrary to traditional drives, the sizing and selection of a torque motor is purely based on torque, not power. Fundamentally, the peak torque determines the maximum torque that the motor physically produces, and the continuous torque defines the amount of torque the motor can continuously supply. The duty cycle of the application will define the dependency on peak or continuous torque designs.

Why adopt torque motors?

Torque motors have a lot to offer engineers. Many applications require precision and accuracy in a variety of industries ranging from Machine Tool to aerospace—torque motors provide benefits that can’t be matched by alternate designs.

1. Reduced cost of ownership

Direct coupling of the payload to the rotor eliminates the need for mechanical transmission elements such as gearboxes, timing belts, speed reducers and worm gear drives. And unlike brushed rotary motors, there is no contact between the rotor and stator; therefore, there is no mechanical wear resulting in excellent reliability and long lifetimes. Fewer mechanical parts also minimize maintenance and reduce the system cost. The direct-drive technology, intrinsic to a torque motor system, results in an efficient and effective gearless assembly.

2. Easy integration

The use of magnets and limited air gap results in a large hollow shaft or bore for easy integration of cables, cooling tubes or other application-related equipment. The ring-like configuration of a torque motor minimizes the volume required for mounting. This gives the machine designer great flexibility in locating the motor to work with bearings, feedback devices and payload. Additionally, to keep up with the latest technology and application requirements, redesigns such as the TMB+ have enabled torque motors to achieve more torque, speed, sizes and variants and reduce heat while remaining pin-to-pin compatible with previous models.

3. Dynamic performance

Dynamic performance is drastically improved by very high control loop bandwidth. The direct coupling of the load and position feedback to the motor has the advantage of eliminating all phenomena that limit the dynamic performance on non-direct driven machines. Eliminating long-time drift, elasticity and backlash is a huge advantage for machine performance and lifetime. Torque motor applications have a wide range of dynamic performance requirements. Depending on the specifics of a system’s duty cycle, the peak torque, continuous torque or both will drive the selection of a motor.

4. Torque motors have an extensive working range

As long as the motor isn’t pushed past its force limit or overheated, adjusting the duty cycle of a torque motor is simply a matter of making changes to the controls. Torque motors are able to easily switch between high torque to high-speed motions without any mechanical adjustments. This versatility in the motor allows it to perform more complex duty cycles and extends its working range as opposed to other methods where parts need to be changed.

In the case of ETEL’s award-winning TMK torque motor, these capabilities are stretched out even further with its unique design using a special magnet configuration which allows it to operate both at low torque/high speed as well as low speed/high torque operations to a much greater degree than traditional magnet shapes.

5. Quiet Shop Floor

While the removal of a gearbox might seem like a large undertaking, direct-drive motors have fewer moving parts than their geared counterparts. This translates into reduced vibration, noise and torque ripple. In addition to quieter operations, elimination of belts and chains eliminates one entire class of motor failure.

Industry Application Example: 5 Axes Milling and Turning

Hermle, an ETEL partner, milling and turning machines are able to switch between milling which uses torque motors for low speed/high torque applications and turning mode which requires a motor that gets high speed/low torque operation. This is able to happen within a single machine because of the TMK torque motor technology.

Other relevant industries in which torque motors play key roles include semiconductors, factory automation, robotics and machine tooling.

General Tips For Choosing A Torque Motor

Many factors need to be considered when choosing a torque motor to ensure outstanding system performance:

- Motor sizing

- Detent effects

- Motor constant

- Thermal considerations

You can read our more technical article How to choose the right torque motor which goes in-depth on these four considerations.

The HEIDENHAIN Family of Brands has long been dedicated to the development of direct-drive technology. Through numerous innovations and patented designs, we continue to provide unmatched torque efficiency for the most optimized performance.