October 24, 2009

Torque in servo motors

- Calculating, measuring and monitoring torque of servo motors is important to ensure system performance regardless of application.

- Different types of torque measurements exist but when specifying servo motors for machine tools, rated torque is the most commonly used specification

- It is important to consider ambient temperature and operating RPM, as well as maximum temperature, to avoid internal damages.

- Torque testers/sensors, velocity sensors, force sensors and torque curves can provide insight into servo motor performance.

Updated on June 10, 2020

What is torque in servo motors?

When specifying servo motors for applications like a new machine or CNC retrofit, there are many considerations regarding servo motor performance and sizing. One of the most confusing is the differing torque capabilities of the motor. Torque can be measured in Newton meters (Nm) or more commonly foot pounds (lb-ft) or inch pounds (lbf-in).

1Nm = 0.74 lbf-ft = 8.85 lbf-in

Torque – Also called moment of force, it can be defined as the mechanical work generated by the turning effect produced when force is applied to a rotational axis. Or the measure of how much a force acting on an object causes that object to rotate.

Stall Torque (MO) – The torque that is produced by a device when the output rotational speed is zero or the torque load that causes the output rotational speed of a device to become zero – i.e. to cause stalling.

Max. Torque (Mmax) – Also known as peak torque, the greatest amount of torque the motor can generate for a very short time period (typically specified in ms). Put another way, this is required only intermittently, not for sustained periods of time.

Root Mean Square (RMS) Torque – This measurement considers how torque varies and sustains during different stages of a motor’s operation, including accelerations, constant velocity, deceleration and dwell.

Rated Torque (MN), Root Mean Square (RMS) Torque or, most commonly, Continuous Torque – This measurement considers how torque varies and sustains during different stages of a motor’s operation, including accelerations, constant velocity, deceleration and dwell. It’s the maximum continuous torque available at the rated speed that allows the motor to do the work without overheating (typically specified at a temperature). This is the working range of the motor.

When specifying servo motors for a machine tool application, Rated Torque is the most commonly used specification. Although different factors can affect the actual value of the torque, it still makes a good baseline as it acts as an average value. Examples of factors that can affect the rated torque are ambient temperature and operating RPM, and it’s factors such as these that need to be understood as a motor is selected. Servo motors also have a listed maximum temperature which cannot be exceeded without damages which needs to be taken into account because if a motor overheats and has internal damages it cannot be repaired.

How to Measure Servo Motor Torque on a Machine

Calculating, measuring and monitoring the torque of your servo motors is an important step to ensure your system performs as it should, when it should, regardless of application. Monitoring changes in torque usage or output can also inform maintenance and help prevent catastrophic failure. Here are a few ways you can measure servo motor torque:

Calculating, measuring and monitoring the torque of your servo motors is an important step to ensure your system performs as it should, when it should, regardless of application. Monitoring changes in torque usage or output can also inform maintenance and help prevent catastrophic failure. Here are a few ways you can measure servo motor torque:

Torque Testers or Sensors

These tools can be attached to the engine shaft and provide measurements as the servo motor runs clockwise or counterclockwise. A tester is more of a quality control device used to calibrate during downtime while a sensor can provide real-time readings and record torque measurements.

Velocity Sensors

To use velocity sensor readings to figure torque rating, monitor the acceleration and velocity at the moment of inertia when moving a large load. You’ll find the relationship between torque and speed provides insight into how the motor is performing.

Force Sensors

Use a force sensor at a known distance by multiplying the distance by force minus any known variables or inaccuracies.

Torque Curves

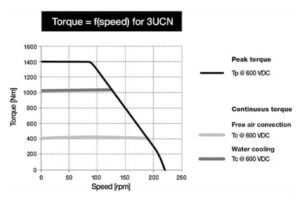

Torque curves are common and simple visual representations that explain a lot about a servo motor’s torque performance. They make it quick and easy to see how things like speed (e.g. RPMs), temperature, peak torque and continuous torque relate.

Top Trends in Direct Drive Motor Technology

Motor technology is advancing rapidly and that includes increases in force density, of which torque is a key element. In fact, getting more output from smaller systems tops our recent list of six trends in direct drive motor technology:

1. Increases in Force Density

2. More Size Options

3. Simplified Integrations

4. More Winding Options

5. New Ways of Integrating

6. Greater Efficiency

To read more about the latest trends in direct drive motor technology, click here. And to learn more about how motors are deployed specifically in CNC machines, from the characteristics that make them useful to how they differ from stepper motors, click here.