July 20, 2015

Technical TidBit: Advantages of absolute encoders and pure serial interface

Provided by Bob Setbacken, HEIDENHAIN Product Manager, Leine & Linde

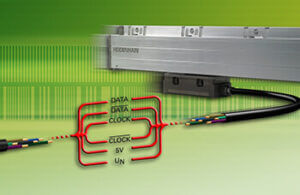

Absolute encoders transmit position information digitally. All signal compensation and interpolation techniques required to obtain the position measurement are done locally in the encoder position measurement sensor. This drastically reduces the potential for noise insertion as the sensor is a carefully designed ASIC surrounded by well-designed shielding and localized power supply filtering.

Absolute encoders transmit position information digitally. All signal compensation and interpolation techniques required to obtain the position measurement are done locally in the encoder position measurement sensor. This drastically reduces the potential for noise insertion as the sensor is a carefully designed ASIC surrounded by well-designed shielding and localized power supply filtering.

The interpolated position value is then transmitted digitally at high speed using Manchester encoding with CRC error detection and correction. In addition, diagnostics for absolute position sensors are generally more advanced than what is available for incremental devices. This is a huge difference in comparison to incremental feedback systems which may be able to detect an error, but almost nothing can be done to recover from such an event.

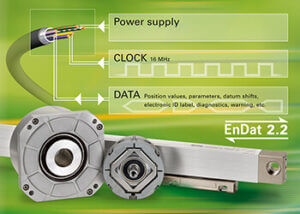

The position value of a true absolute encoder is always available. No motion of any kind is needed to determine where the controlled element is positioned. This means that after start-up or power loss, motion can immediately resume without a return to Home or hunting procedure for a local reference.

With the use of an EnDat 2.2 pure serial interface with the absolute encoder, an extremely high data transfer rate is supported by automatic error detection and optional real-time sensor diagnostic information. The serial communication of a digital position value eliminates transmission noise issues, and integrated diagnostics allows condition monitoring systems to schedule maintenance activities rather than react to system failures. The result is higher throughput and increased capacity through higher availability.