June 17, 2025

Smarter measuring, better machining: the HEIDENHAIN touch probe advantage

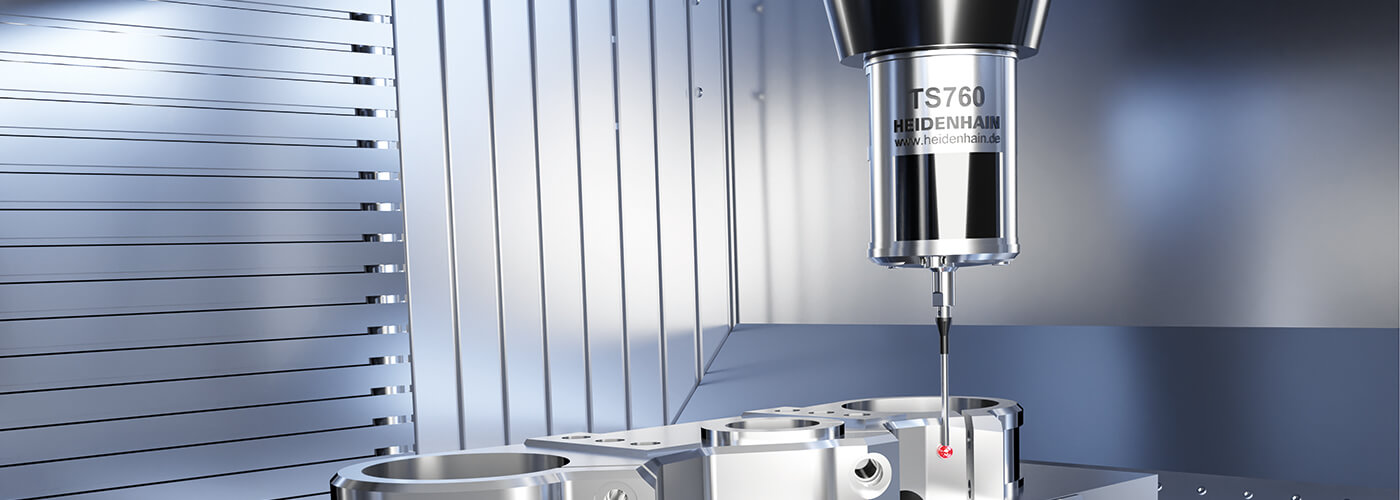

In machining, we understand that every micron counts and every minute matters, and the ability to measure and inspect directly within the machine tool environment isn’t just a convenience—it’s a competitive advantage. HEIDENHAIN’s touch probes are leading this shift, delivering precise, reliable in-process metrology that enhances both accuracy and efficiency on the shop floor.

Beyond setup: touch probes as metrology tools

Touch probes have long been used for part alignment and basic tool setting. But with the evolution of 5-axis machining and precision CNC systems, HEIDENHAIN’s probes have transformed into true metrology tools—enabling real-time inspection, automated compensation, and smarter decision-making without ever removing the part from the machine. This leap forward empowers machinists to reduce inspection time, avoid rework, and catch errors before they cost hours in downtime.

In-process accuracy starts with the right touch

HEIDENHAIN offers a wide range of high-performance touch probes—each engineered with features that promote durability, precision, and intelligent operation. From compact cable-connected models to sophisticated wireless solutions, each probe is built with wear-free optical sensors, optional collision protection, and integrated cleaning channels that remove chips before measurement, ensuring dependable results and less operator intervention every time.

Take the TS 460 and TS 760 workpiece touch probes. With probing repeatability down to ≤1 µm and even 0.25 µm respectively, they ensure that the very first measurement is the right one—eliminating repeat probing cycles and reducing idle time. These probes are also designed to operate wirelessly using infrared or radio transmission (or both), providing robust communication without interfering with other systems. Thanks to their high probing speeds—up to 3 m/min—and smart integration with HEIDENHAIN’s TNC controls, they offer intuitive setup, diagnostics, and real-time feedback.

Protecting the process, preserving the machine

Machine downtime due to a broken probe or damaged spindle is every operator’s nightmare. That’s why HEIDENHAIN integrates thermal insulation and collision protection into its touch probes. In high-duty cycles or after extended cutting operations, heat transfer from the spindle can distort measurements unless a thermal barrier is in place. Likewise, should a collision occur during complex 5-axis moves, probes like the TS 460 are designed to give way, absorbing the impact and preventing damage to critical components.

Clean workpieces, clean results

Chips matter—and not just when cutting. Residual chips can mislead measurements, especially in tight-tolerance applications. That’s why HEIDENHAIN’s probes feature integrated cleaning channels for coolant or air through the spindle, capable of clearing the measurement area with up to 60 bar of pressure. This seemingly small feature makes a major difference in reducing inspection time, maintaining consistency and avoiding scrap.

Tool probing for a complete picture

Workpiece probes are only part of the equation. Tool touch probes like the TT 460, TT 160, and the TD 110 tool breakage detector play a key role in keeping processes reliable. These devices allow for precise tool length and diameter measurement, breakage detection during rapid traverse, and automated inspection of HSS and carbide microtools down to 0.4 mm.

The TD 110, for example, uses an inductive, non-contact sensor to inspect tools at full spindle speed—eliminating the need for teach-in cycles and drastically reducing idle time compared to laser systems. And because it operates without compressed air or additional cables, it’s easy to retrofit and maintain, further lowering the total cost of ownership.

The power of in-process inspection

Some may argue that part inspection should always happen off the machine in a climate-controlled environment. But for many applications, in-process probing can be not only sufficient—it can be essential. Precision machines with closed-loop feedback systems, like those using HEIDENHAIN’s glass scale encoders, can use touch probes to inspect within tolerance bands accurately. This early insight enables corrective actions before parts are unclamped, saving hours of setup and avoiding wasted material.

Furthermore, advanced probing routines enable 3D tool radius compensation, correcting for subtle deviations in cutter geometry that would otherwise impact surface finish and dimensional accuracy—especially on freeform or sculpted surfaces.

Tailored for today’s machines

From compact solutions like the TS 150 to full-featured wireless probes, HEIDENHAIN’s product lineup is designed to fit every type of machine and application. With seamless TNC integration, real-time signal monitoring, and high-speed communication, these probes reduce setup time, increase uptime, and bring measurement closer to where it matters most—the cut. In addition, all touch probes are compatible with major third-party CNC controls.

In short, HEIDENHAIN touch probes do not simply check parts—they elevate the entire machining process.

By combining precision hardware, intelligent software integration, and robust mechanical design, HEIDENHAIN is redefining how manufacturers think about inspection, measurement, and productivity—one probing cycle at a time.

For more information, reach out to one of our specialists today: https://www.heidenhain.us/about-us/contact-us/