January 23, 2017

Reliability emphasized with the LTN SH085 slip ring

CONTACT:

Jonathan Dougherty, Product Specialist, 847-519-4218

Kathleen Stoneski, PR Manager, 847-519-4702

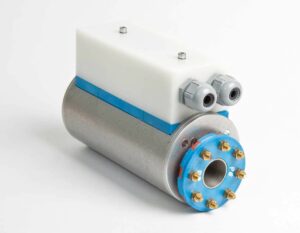

Schaumburg, IL (January 2017) – In the world of packaging and side-sealing machines where downtime can lead to losses of thousands of dollars, a central component’s best ability is its availability. Thus, LTN Servotechnik GmbH has developed the SR/SH085 family of slip rings, specifically tailored to the needs within the packaging industry and engineered to run reliably for a long time.

Schaumburg, IL (January 2017) – In the world of packaging and side-sealing machines where downtime can lead to losses of thousands of dollars, a central component’s best ability is its availability. Thus, LTN Servotechnik GmbH has developed the SR/SH085 family of slip rings, specifically tailored to the needs within the packaging industry and engineered to run reliably for a long time.

Slip rings are used to enable the transmission of electrical signals and power from a stationary to a rotary system in many manufacturing machines. In many situations, they are placed in harsh environments with high amounts of vibration and shock. Due to this exposure, and the natural wear and tear of operation, many slip rings are replaced regularly and cause excessive downtime due to maintenance and replacement. The SR/SH085 from LTN Servotechnik GmbH has been engineered to handle these harsh environmental conditions, and the need for maximum service life received special attention during development.

The SR/SH085 slip rings are available with up to 16 poles, transmitting both data signals and power across the rotary axis, and provide options for high speed applications. The SR/SH085 family of slip rings provide a multitude of different options and customization opportunities to ensure that the product received is tailored to operate to exact needs.

LTN Servotechnik GmbH is based in Germany with exclusive North American distribution through HEIDENHAIN CORPORATION in Schaumburg, IL. LTN specializes in providing components to the international machine builders and plant engineering industry. The worldwide network of sales and service offices is the backbone of the traditionally-oriented company’s global activities. LTN’s product line is largely composed of slip rings and resolvers, leaning on application know-how to provide customers with tailored solutions to individual problems.