August 31, 2022

Protocol: useful PWM 20/21 reporting feature

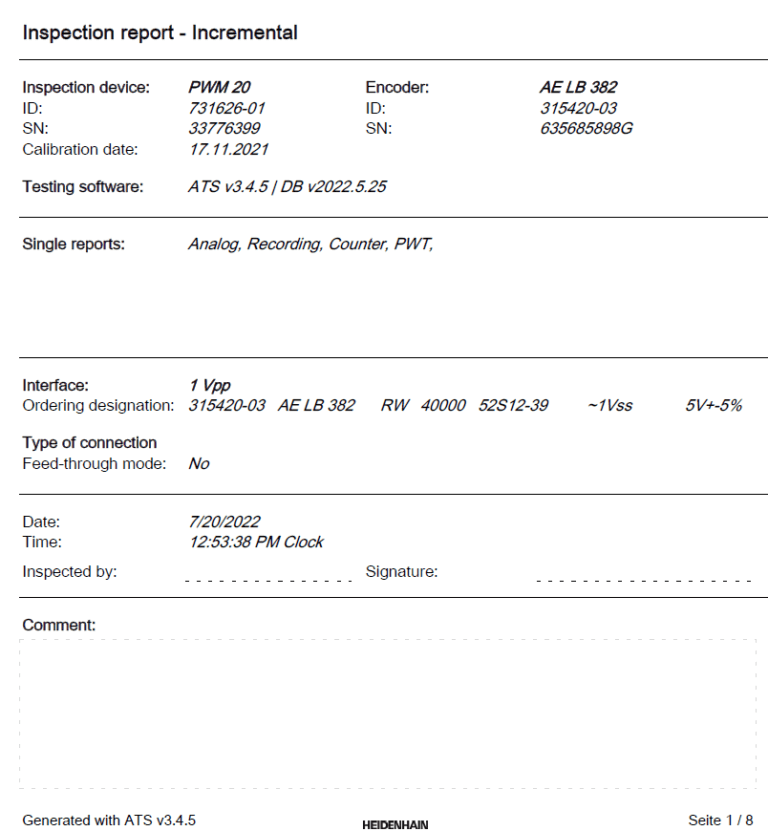

Figure 1: Cover page of inspection report generated from the Protocol view.

![]() By Josh Arevalo, Service Department Lead

By Josh Arevalo, Service Department Lead

Accuracy is a primary consideration in any machine tool application and HEIDENHAIN encoders deliver the highest accuracies in the industry. And that’s why we use and offer for sale PWM 20/21 test devices with ATS (Adjusting and Testing Software) for encoder testing. “Protocol” is one of its many useful features and is described here.

It’s important to note that environmental issues, machine component issues, improper mechanical alignment of encoders, and general wear and tear can affect the signal quality of HEIDENHAIN encoders. Our PWM 20/21 test devices with ATS are an integral part of HEIDENHAIN’s in-house diagnostic and repair services. All repair technicians at HEIDENHAIN CORPORATION have a PWM 20/21 device at their workstation. Many of our Service Partners, distributors, OEMs and end users regularly utilize their own PWM 20/21 test devices to help troubleshoot and diagnose encoder issues in the field.

When a HEIDENHAIN encoder is connected to a PWM test device, its interface type will be automatically recognized after the identification number is entered. The ATS uses the encoder’s identification number to determine what diagnostic tests are supported by the connected encoder and automatically performs all supported tests. During evaluation and final inspection of each repair, all available signals are electronically observed and must be within published specifications.

The Protocol feature of the ATS is useful for viewing the data acquired during a testing protocol. Data from the various ATS measurement functions can be transferred to the Protocol and from this screen, an aggregate of all data can be displayed or saved as a single PDF file. Figure 1 is an example protocol report from the testing of an LB 382 scanning unit. The example report contains the data acquired from the “Analog”, “Recording” and “PWT” functions of the ATS.

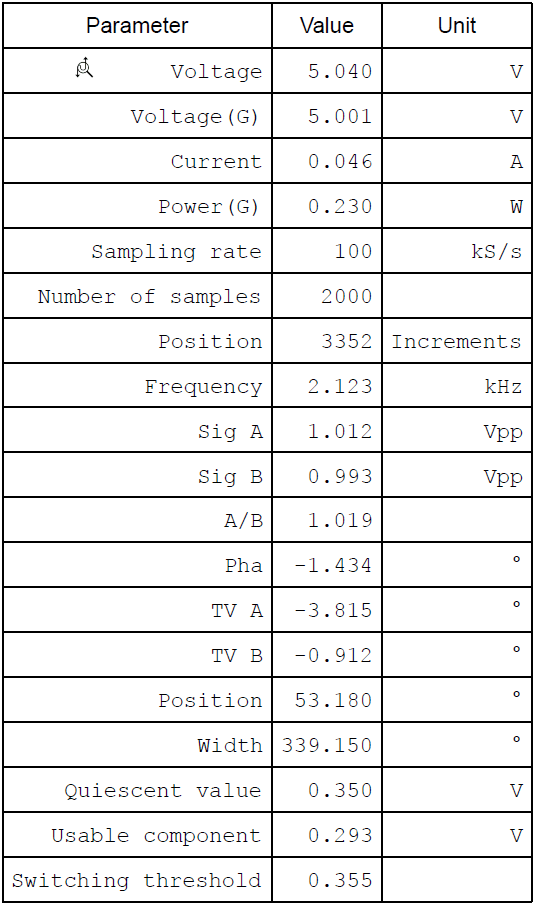

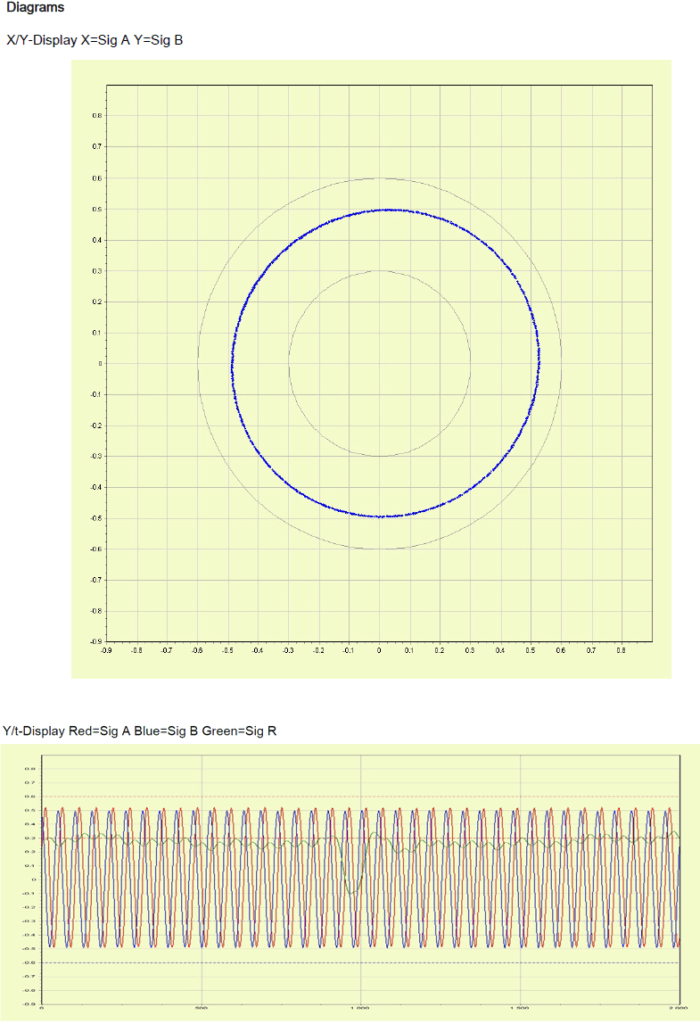

Figure 3: Protocol data acquired during incremental analog measurement in Figure 2.

Figure 2: Incremental analog measurement ia ATS.

Information included in the report for the encoder being tested:

- ID and SN

- Interface type

- Connection type (feed-through or stand-alone)

- Date and time

- Inspector

- Comments (notes found at the time of testing)

- Signal diagrams and all corresponding measured values for tested encoder (Figures 2 & 3)

Whether you are at a customer’s facility or in your own shop, the ATS’ Protocol view can be used to document the results of an encoder’s test protocol before and/or after providing service. The PDF file generated in the Protocol view can be provided to an end-user or stored to be used as a reference for the last inspection of a particular encoder.

If you have any questions about the ATS Protocol feature, or if you are interested in purchasing a PWM 20/21, please contact HEIDENHAIN CORPORATION’s Technical Support team at techsupportHC@heidenhain.com or +1.847.490.0351.