August 5, 2025

Precision in motion: 5 common CNC problems solved with HEIDENHAIN innovation

With shorter lead times, tighter tolerances, and machines expected to do more with less oversight, shops that rely on CNC technology face a moving target. Productivity and precision often clash—especially as parts get more complex and skilled labor becomes harder to find. While many of these challenges aren’t new, the technology to solve them is advancing rapidly.

From improving part accuracy and speeding up setup to preventing costly downtime, HEIDENHAIN and its family of brands—including Acu-Rite Solutions, ETEL, and RSF—deliver practical solutions to the everyday hurdles that shops face. Here are five common machining problems—and how HEIDENHAIN’s innovative technologies solve them without adding complexity for operators or programmers.

Preventing precision drift over time

Even subtle shifts caused by thermal expansion, backlash, or wear can gradually throw off your positioning—especially during long runs. Most systems rely on rotary encoders mounted to the motor, but this approach doesn’t capture what’s happening at the axis itself.

HEIDENHAIN solves this with a closed-loop feedback system that places linear and angle encoders directly at the point of motion. It gives the control system a real-time view of actual machine position, allowing instant correction and consistent precision—even in demanding environments.

The RSF exposed linear and modular angle encoders reinforce this approach. With non-contact feedback, zero friction, and high resolution, they’re ideal for clean environments and applications requiring smooth, accurate motion. Paired with HEIDENHAIN controls, RSF encoders eliminate guesswork, lag, and overshoot.

The RSF exposed linear and modular angle encoders reinforce this approach. With non-contact feedback, zero friction, and high resolution, they’re ideal for clean environments and applications requiring smooth, accurate motion. Paired with HEIDENHAIN controls, RSF encoders eliminate guesswork, lag, and overshoot.

Rotary motion also benefits. The ETEL direct-drive torque motors remove mechanical play while working with high-resolution encoders to ensure ultra-smooth, controlled motion across all speed ranges. Combined with HEIDENHAIN and RSF technologies, shops get tight control over every axis—linear or rotary—without sacrificing performance.

Simplifying setup and reducing changeover time

For short runs or frequent part changes, setup time is often the hidden bottleneck. Aligning stock, setting tools, and adjusting offsets can eat into production. HEIDENHAIN combats this with touch probes and automated setup routines that integrate directly with TNC controls. These visual, step-by-step sequences walk operators through the process, automatically calculating offsets and reducing the chance of human error.

Acu-Rite Solutions also plays a significant role here. Its user-friendly CNC controls for mills and lathes are built for everyday machinists—whether it’s a small shop or a student learning the ropes. The interface is easy to navigate without giving up the functionality needed for serious work. Paired with HEIDENHAIN’s advanced systems, this makes precision accessible at every skill level.

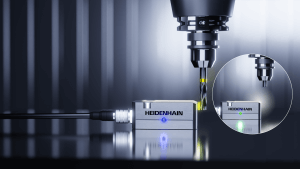

Catching tool breakage before it costs you

Tool failure doesn’t always make a dramatic entrance. A fractured cutter can silently destroy a part—or worse, damage your spindle—if not detected in time. That’s where the HEIDENHAIN TD 110 tool breakage detector comes in. Using inductive, non-contact sensing, it monitors for broken tools in real time—without ever touching them. It’s ideal for high-speed machining or delicate tooling.

When paired with the TNC7 control, the system instantly alerts operators the moment breakage occurs. It helps avoid rework, unplanned downtime, or machine damage—especially during unattended shifts or critical parts runs.

Empowering operators with smarter interfaces

Empowering operators with smarter interfaces

The best CNC controls don’t just manage machines—they empower the people who run them. As shops bring in new talent or cross-train existing staff, usability matters more than ever. HEIDENHAIN’s TNC7 is designed for this shift. With intuitive multi-touch controls, customizable layouts, and adaptive on-screen guidance, the TNC7 reduces onboarding time and operator errors.

A standout feature is on-screen contour drawing. Operators can sketch a part right on the control, and the system automatically generates the machining code. It eliminates the need for external CAM software for many everyday tasks and helps teams ramp up faster with less training.

Boosting speed without sacrificing surface quality

High feed rates often come at the cost of finish quality—but HEIDENHAIN makes it possible to have both.

With features like Cycle 32, TOLERANCE, 3D-ToolComp, and ADP (Advanced Dynamic Prediction), toolpaths are constantly optimized in real time. These functions minimize vibration, refine transitions, and smooth motion—even at high speeds.

ADP is especially powerful, adjusting for inconsistent NC code to ensure consistent motion through complex geometries. That means faster production without risking part rejection due to poor finish or dimensional errors.

Smarter technology. Smoother results.

Solving machine tool challenges isn’t always about buying bigger equipment—it’s about making your current systems work smarter. With intelligent controls, precision feedback, and user-friendly interfaces, HEIDENHAIN and its brands help you do more with what you already have.

By combining proven hardware, modern usability, and a collaborative technology ecosystem across RSF, ETEL, and Acu-Rite Solutions, HEIDENHAIN offers a complete framework for smarter, more reliable machining—from setup to finish.

To see how these innovations can support your goals, visit www.heidenhain.us