Thermals and drift under control

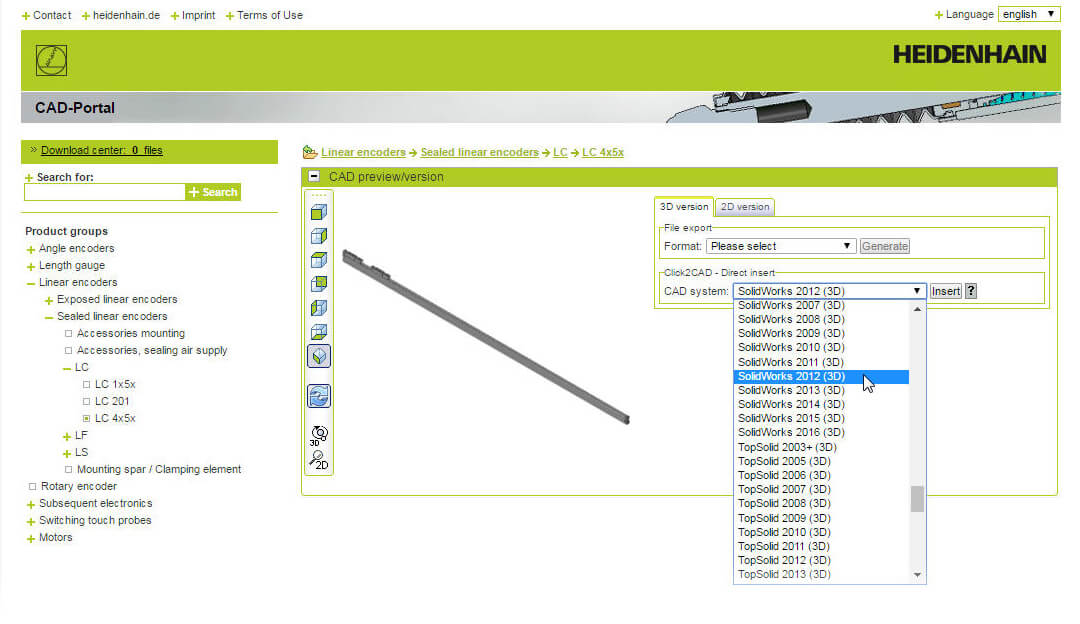

24/7 access to CAD models and product info

Fast, accurate and fine positioning

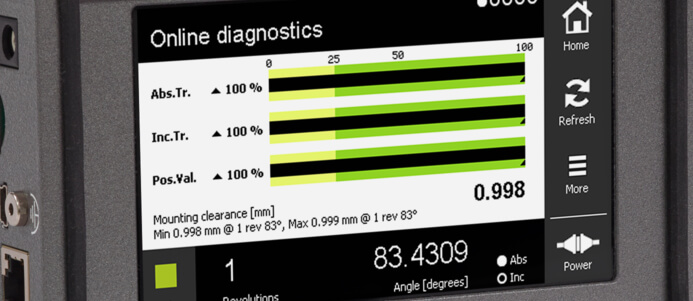

HEIDENHAIN introduces mobile encoder diagnostics tool

Greater margins for tolerances

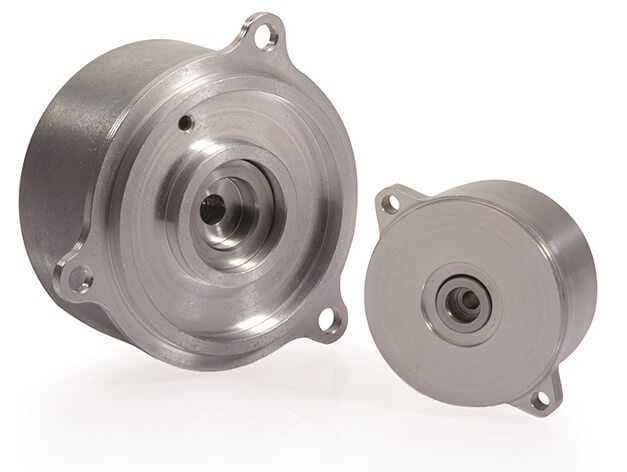

The extreme encoder for extreme applications

Did you know that ETEL linear motors are used in metrology applications?

Accuracy and safety significantly improved

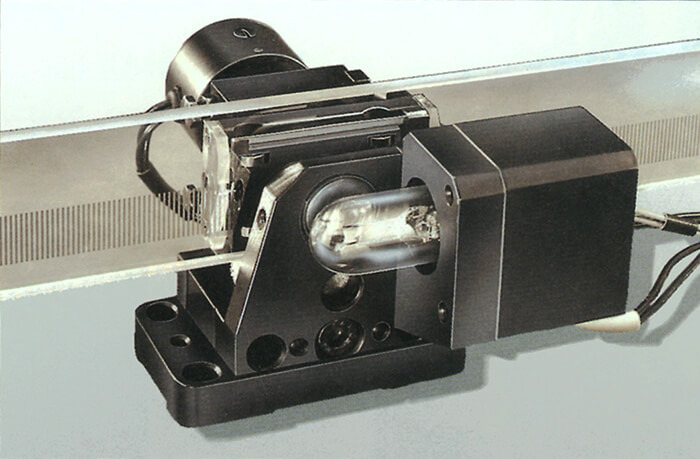

Successful LIDA 400 exposed linear encoder is redesigned for the future of motion feedback

The history of the encoder

Filter by topic