March 22, 2021

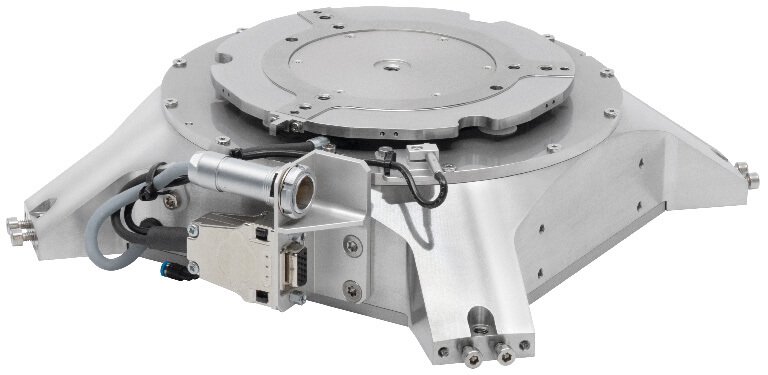

New high accuracy ETEL DXRH rotary system

SAN JOSE, CA (March 2021) – With the introduction of the new high precision DXRH rotary axis system, ETEL once again offers those involved in the development and use of highly accurate semiconductor/electronics machines a new and better Theta axis option as either a stand-alone or system-integrated solution.

SAN JOSE, CA (March 2021) – With the introduction of the new high precision DXRH rotary axis system, ETEL once again offers those involved in the development and use of highly accurate semiconductor/electronics machines a new and better Theta axis option as either a stand-alone or system-integrated solution.

ETEL’s new DXRH incorporates the best-in-class encoder (360,000 lines) and bearing technology from parent company HEIDENHAIN, as well as ETEL’s toothless (Ironless), zero torque ripple direct drive technology for high speed stability. Because of its unmatched mechanical characteristics due to the combination of HEIDENHAIN’s components and ETEL’s direct drive motor technology, it is comparable to air bearing solutions without the associated complexity.

The DXRH was designed in response to the needs of the semiconductor industry, being especially suitable for Wafer Process Control applications such as Overlay Metrology, Critical Dimension and Thin film Metrology. It is also well suited for photonics applications, either as an extension of ETEL’s already advanced CHARON2 and VULCANO2 platforms or to be integrated into other systems.

The DXRH provides a high accuracy of ± 3 arcsec without calibration, position stability of ± 2.5 marcsec, bidirectional repeatability of ± 0.25 arcsec, and a radial runout of ± 1µm. The module is ISO class 1 clean room compatible.

ETEL S.A. is based in Switzerland with exclusive North American distribution through HEIDENHAIN CORPORATION in Schaumburg, IL. As a leading international supplier of direct drive and motion control components and integrated systems, ETEL supports high tech industry with linear motors, torque motors, positioning stages, and motion controllers/systems.

More ETEL information can be found at: https://www.heidenhain.us/products/direct-drive-motors-motion-systems/

High-resolution image available here.

Product contact:

Brian Zlotorzycki, Business Development Specialist, ETEL Motors

847-755-5569

Media contact:

Kathleen Herrmann

224-520-0665