November 18, 2021

5 jaw-dropping motion control facts

How incredibly far we have come in the world of precision measurement; advances in motion control technology continue to boggle the mind. We’re lucky to have a front row seat. From small components that offer tiny nanometer measurements to extraordinarily large torque motors that propel equipment in ways never before possible, we’ve been at the forefront of rapidly developing precision motion control breakthroughs. Here are just a handful of jaw-dropping examples.

Jaw-dropping fact #1 – The RCN 8000 angle encoder has 536,870,912 positions.

Absolute angle encoders provide a unique serial word or bit sequence for every position reported. Their advantage is that when a machine starts up, it automatically knows where it is along the travel distances and does not have to spend time referencing the motion system. HEIDENHAIN offers the highest resolution absolute angle encoders, used in a variety of industries including machine tool rotary tables, grinding axes, large astronomical telescopes and radar dishes.

The latest model of HEIDENHAIN’s RCN 8000 absolute angle encoder series can report an astounding 29 bits of absolute information; each position is unique for all 536,870,912 positions around a 360-degree circle! Large structures like astronomical telescopes that weigh tens of tons or more can and do use this positioning technology to achieve incredible pointing accuracies and tracking capabilities that help find extra-solar planets, faint asteroids that may be worrisome or other interesting objects in the universe.

Jaw-dropping fact #2 – Writing a hard drive’s base tracks requires resolutions down to 2 nanoradians.

In the world of spinning hard drives—which aren’t going away any time soon, due to price point vs. data storage capacity—angle encoders are used as the critical measurement source needed to write the base data tracks on them. These base tracks are important so that the hard drive can continue to write itself offline in order to be ready for consumer use.

The angle encoders that are often used to write those base tracks start with an analog signal period of 360,000 lines on a diameter of 108mm. Then, after interpolation of the analog signals, the machines used in writing the base tracks can have resolutions of down to 2 nanoradians or 0.00041 arc seconds.

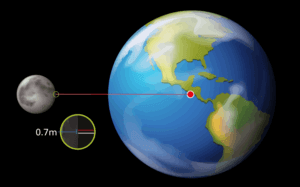

To provide a perspective on how small that angle is, if you were to project the vertex of that angle starting from the center of the Earth outward toward the surface of the Moon, the angle width would be only about 0.7m across!

Jaw-dropping fact #3 – The 1.3-meter ETEL TMB+ torque motor can output 43,000Nm of torque.

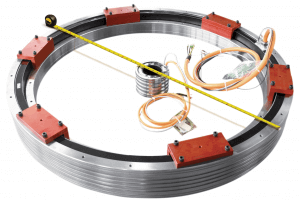

Often in the past, when a motor application required a large degree of torque, manufacturers often had to custom build a direct drive motor. On the other hand, the ETEL TMB+ torque motor has a maximum diameter of over 4 feet (1.3 meters), outputting a maximum torque of around 43,000Nm!

This ETEL torque motor is called the TMB+1221. Whereas most direct drive motor lines tend to only get as large 2 to 2.6 feet, the enormous TMB+1221 is offered as a completely standard product, purchasable the same way as any other size. This includes all the same options as its other smaller variations, such as options of five different heights, four winding options, and closed cooling availability.

ETEL torque motors of this size are already in the field and can be found worldwide. This includes many largest-scale machine tool rotary tables where the giant metal parts are cut, such as the aerospace industry. These giant torque motors can also be found on grinding machines that make gears used on oil rigs. Another common use is in large scale telescopes where heavy payloads need to be moved with the precision and reliability that direct drive motors provide, to name just a few.

Jaw-dropping fact #4 – Each position of the LIC 4100 linear encoder can be as small as 5 silicon atoms.

![]()

HEIDENHAIN’s absolute encoders provide a unique position value for every position, i.e. every position on an absolute encoder is different. For the LIC 4100 encoder system, each position can be 1 nanometer, or a billionth of a meter, which, in the real world, is 5 silicon atoms. These unique position values can continue for a graduation/scale that can be up to 28.4 meters long, thereby providing 28.4 billion unique position values across 1 long encoder.

Jaw-dropping fact #5 – The LIP 200 encoder can be interpolated to yield resolution down to the width of a single water molecule.

![]()

Our LIP 200 series linear encoders start with a 512-nanometer signal period, and that can be safely interpolated 16,384 times, yielding an end resolution of 31 PICOMETERS! That distance of 31 picometers, which translates to the width of a single water molecule, can be measured at a rate of 3m per second or as fast as you can run.

The pace of change is hard to comprehend. But, with such deep roots in R&D, these kinds of challenges are what we thrive on. The goal is always to push things forward instead of reacting, so that we can help, and be part of the breakthroughs that keep progress moving.