May 10, 2014

Leine & Linde encoders with HC-HTL outputs drive up to 350 meter cable

CONTACT:

Bob Setbacken, Product Manager 805-562-1160

Kathleen Stoneski, PR Manager, North America, 877-565-9151

SCHAUMBURG, IL (May 2014) –

SCHAUMBURG, IL (May 2014) –

The ability to drive long cables and meet the high and low level voltage requirements for the transmitted signal is what sets the Leine & Linde High Current TTL (HC-TTL) output circuitry apart from its competition.

The length of cable an encoder is capable of driving depends upon many factors. The cable type, mechanical properties, and overall length determine the capacitance and resistance the encoder output drive electronics must handle. This type of load will ultimately limit the amplitude and frequency of a signal transmitted.

In the 700 or 800 series encoders, the HCHTL outputs can drive a 0-30V square-wave signal with frequency of 100kHz. Signal quality exceeds industry standards for voltage amplitude and signal rise-time while driving as much as 350 meters (~1150 ft) of cable when terminated into a 40ma resistive load. Signal integrity is maintained with temperatures ranging from -40 to 85 degrees Celsius.

Lower frequencies would allow for even longer cables.

For more information, contact Bob Setbacken at HEIDENHAIN at 805-562-1160, or write to HEIDENHAIN Corporation, 333 E. State Parkway, Schaumburg, IL 60173.

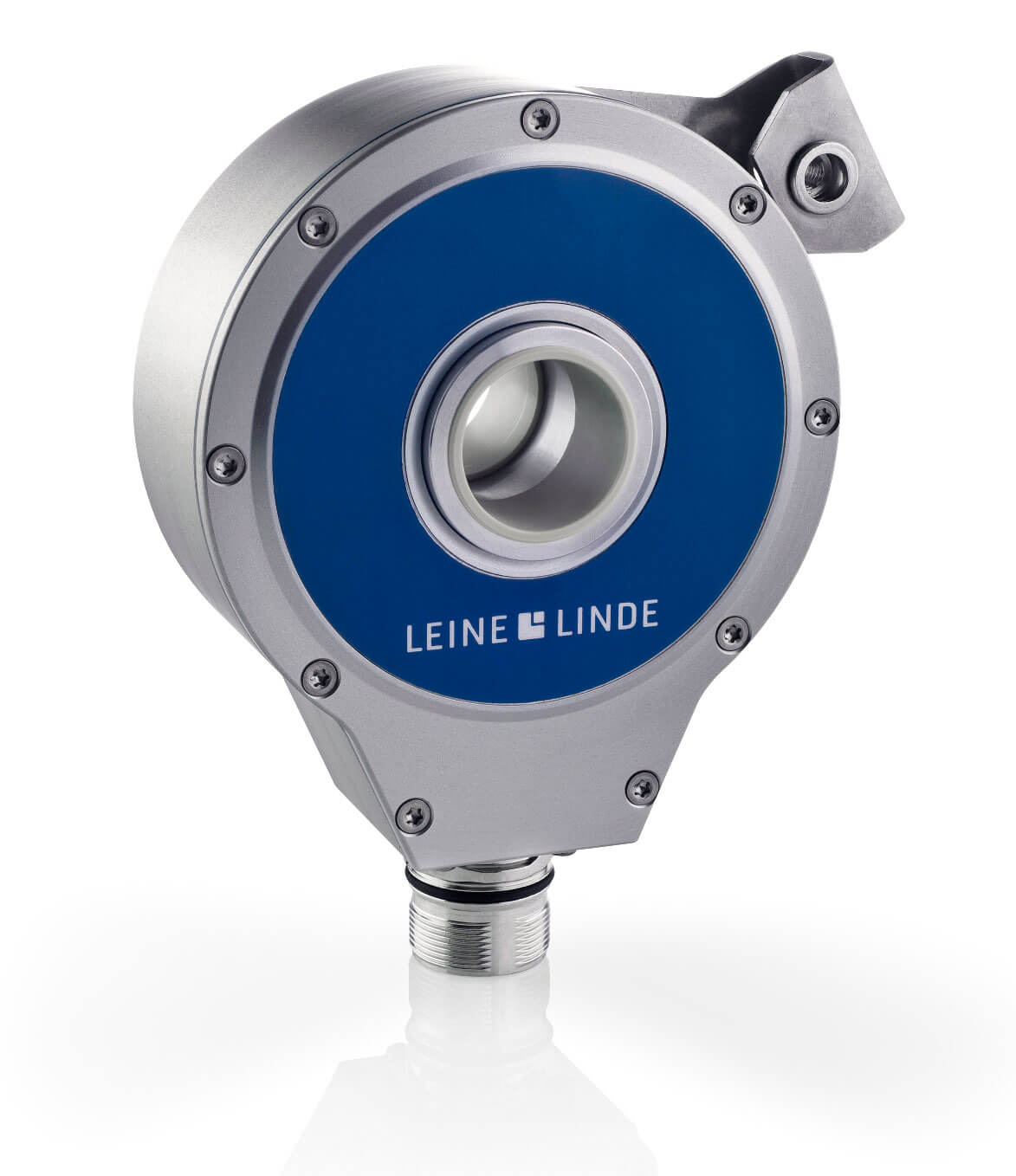

Leine & Linde is based in Sweden with exclusive North American distribution through HEIDENHAIN Corporation in Schaumburg, IL. Leine & Linde is well known for offering high quality, heavy duty encoders of both the incremental and absolute types, are noted for their product robustness and design to cope with the harshest of environments, such as those with high vibration, dirt and cold temperatures. These heavy, severe duty encoders are suited for drive and measurement applications and are often found in industries such as pulp and paper, forest and wood processing, agriculture, aggregate and mining equipment.