June 1, 2015

LEINE & LINDE 862 encoder now includes mechanical enhancements for Functional Safety

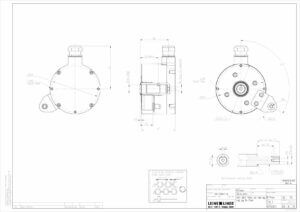

Leine & Linde XHI862

CONTACT:

Bob Setbacken, Product Manager, 805-562-1160

Kathleen Stoneski, PR Manager, North America, 847-519-4702

Schaumburg, IL (June 2015) – When an automation system which includes an encoder must be certified to a specific Performance Level (PL) or Safety Integrity Level (SIL), the design of its safety system must consider both mechanical and electrical details. For those instances, the Leine & Linde 862 rotary encoder series with modified hollow shaft is now available.

The mechanics of a machine safety system must provide a primary and secondary fixation method of an encoder shaft to the active machine. The LEINE& LINDE XHI862 encoders certified for Functional Safety applications include a dowel pin within the hollow shaft to engage with a complimentary slot in the machine shaft to do just that.

The engagement of the encoder pin (4mm in diameter) and motor shaft slot assure that the encoder will be properly mounted and engaged with the machine even if the primary fixation should fail.

MTTFd and PFHd values are provided with the product documentation.

Electrical interfaces include sinusoidal (1 Volt peak-peak) and High Current HTL. The reliability of each version is established per EN ISO 13849-1 and IEC 61508.

For more information on these encoders, contact Bob Setbacken at HEIDENHAIN at 805-562-1160 or write to HEIDENHAIN Corporation, 333 E. State Parkway, Schaumburg, IL 60173 or e-mail at bsetbacken@heidenhain.com

Leine & Linde is based in Sweden with exclusive North American distribution through HEIDENHAIN Corporation in Schaumburg, IL. Leine & Linde is well known for offering high quality, heavy duty encoders of both the incremental and absolute types, are noted for their product robustness and designed to cope with the harshest of environments, such as those with high vibration, dirt and cold temperatures. These heavy, severe duty encoders are suited for drive and measurement applications and are often found in industries such as pulp and paper, forest and wood processing, agriculture, aggregate and mining equipment.