March 5, 2013

HEIDENHAIN’s new large-bore inductive encoder available for motor markets

CONTACT:

Jimmy Rago, Product Specialist, 847-519-4213

Kathleen Stoneski, Public Relations Manager, 877-565-9151

SCHAUMBURG, IL (March 2013) –

SCHAUMBURG, IL (March 2013) –

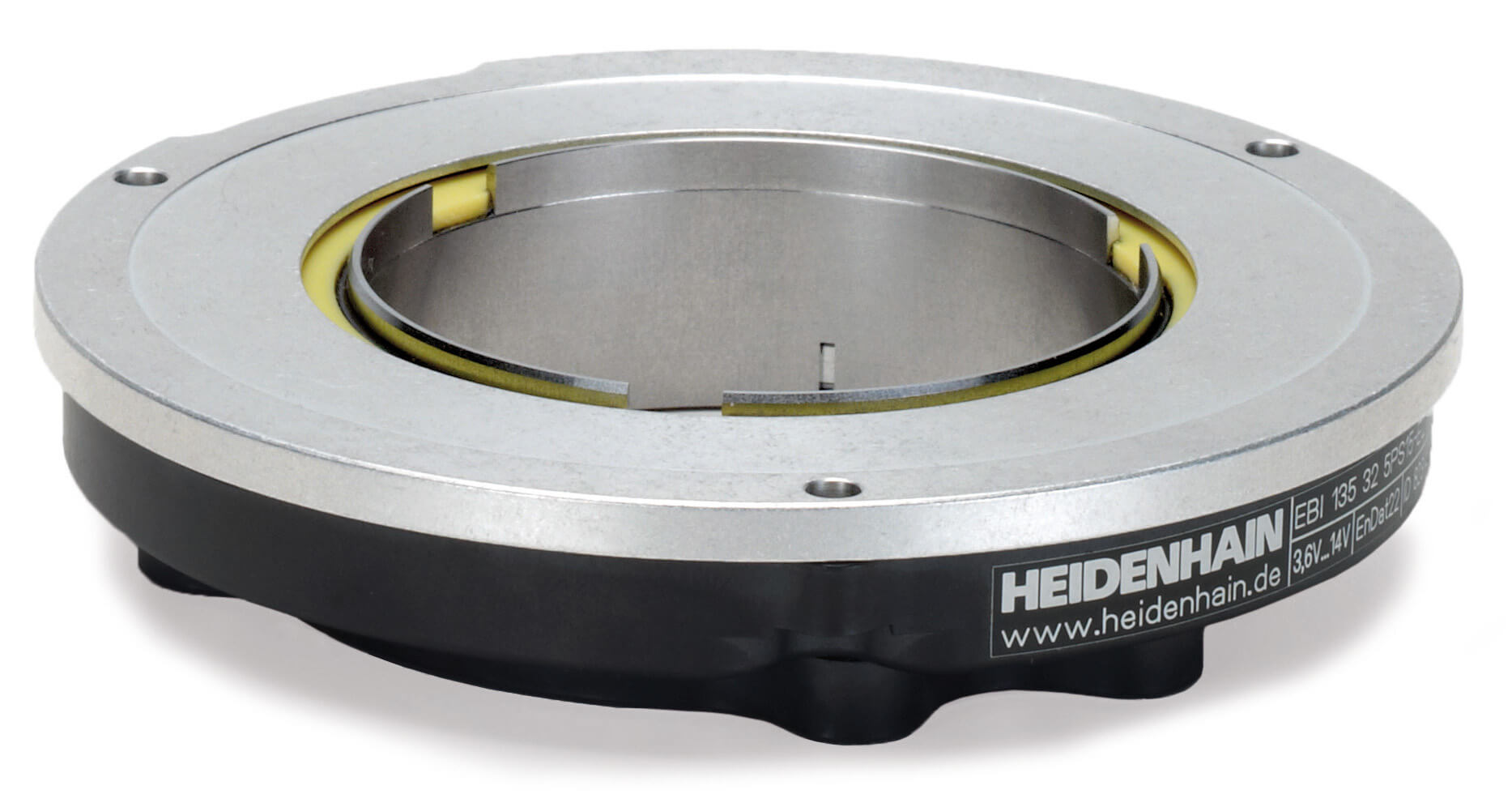

A new large bore rotary encoder offering high resolution and support of external temperature measurement is now available from HEIDENHAIN Corporation. This encoder called the EBI 135 opens up new markets for HEIDENHAIN products such as for use in hollow shaft gear motors, hollow shaft servo motors and torque motors used in plastic injection molding machines.

An inductive, battery-buffered multi-turn absolute encoder, this EBI 135 is available in 30 mm, 38 mm and 50 mm diameters. It is available with EnDat 2.2 interface and has a large voltage supply of +3.6V to +14V.

Since the EBI 135 uses the inductive scanning principle along with an electronic revolution counter, the encoder is particularly robust against vibration and contamination. There is no mechanical multi-turn gearbox which means less possible sources of failure.

The EBI 135 large-diameter, hollow shaft encoder is in essence a contactless solution with no bearing, so backlash and mechanical heating from friction are not a worry. The rotor and stator are also mechanically isolated from each other, meaning any ripple currents in the motor shaft are not transmitted to the encoder. An upper temperature range of +115°C allows motors to be pushed to higher temperatures and more efficient utilization.

Size and shape of the EBI 135 is especially conducive to efficient machine design thanks to the small stack height (18.5mm) and large through hole which permits the routing of cables, shafts, supply lines, or even lasers through the encoder shaft.