July 27, 2021

How to choose the right encoders for semiconductor machinery

You can have all the bandwidth, AI, or optics in the world, but none of it matters if a semiconductor tool cannot meaningfully reach nanometer level precision without compromising its throughput. When the goal is to make precise measurements as quickly as possible, the max speed of a motion system’s axis won’t matter if it’s measuring a point on a wafer with too long of a settling time.

There are all kinds of tradeoffs like this in the nanometer, high-throughput world of semiconductors. Although drive system and structural integrity play a role, the encoder is vital to achieving the combination of speed, accuracy, and stability needed for the advanced processes.

Choosing the right motion feedback solution

To meet a machine’s requirements, engineers currently have a variety of motion feedback solutions to choose from with both linear and rotary movements. Despite the growing amount of new technology, the factors which are considered are similar across all encoder types. Here are some points to take into account when deciding on the right product.

- What environmental conditions must the encoder endure (vibration, vacuum, temperatures, etc.)?

- Are there any mechanical restrictions which may affect the space available or method of encoder mounting?

- What level of accuracy will you need?

- What speed will this accuracy be reached?

- How much interpolation error can you afford?

Check the specs

As these are determined, then the options are narrowed down. An early choice may be the type of encoder: mechanical, optical, magnetic, or induction. For example, if a process takes place in a vacuum and is very space restricted then the choices would be narrowed down to products such as the Numerik Jena LIK 41 or KIT L Series. If the vacuum application requires high precision, such as in photomask fabrication, then depending on the interface, the LIF 471V or 481V may work. For extreme accuracy, the LIP 481V may be better. From there it’s a matter of looking at more specifications in the catalogue to make the final choice.

The measuring standard matters

Whether it’s linear or angular, another key part of an encoder’s capability is its measuring standard, or the graduation on a scale tape. A scale’s line count gets a lot of attention, but how these lines are created (applied to the scale) at defined intervals is important too. It’s so important, we invented our own processes. OPTODUR, SUPERADUR, and METALLUR designs form 3D structures with very high edge definition and resistance to contamination that can disrupt front- and back-end semiconductor work. The structures have a very low height, leaving practically no surface for dust, dirt, or liquid to accumulate. The encoder graduation plays a big role in not only upfront performance, but keeping quality consistent over time.

Trust, but verify

In the semiconductor world, each and every component of a machine has very high standards and an engineer wants parts that they are confident could get the job done. When an encoder is selected, there’s an expectation that the product is thoroughly tested and verified to meet very specific standards. Our catalogs are chock full of extreme testing results and verified specifications so you can have confidence that each component will perform to its values.

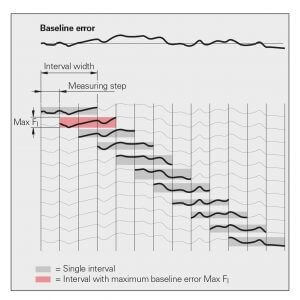

Just one example, we go as far as to test intervals within an encoders scale so users can better predict performance. We first define the interval width for which the accuracy is to be stated. Then, the scale is continually measured over its entire measuring length in defined, very small measuring steps with the chosen interval width. Finally, the uncompensated baseline errors over each interval width are evaluated. The worst value, i.e. the greatest measured baseline error over all measured intervals, is then specified as the maximum value of baseline error on that encoder.

Ascertainment of accuracy over one interval.

Ascertainment of accuracy over one interval.

With this level of testing at our disposal, a constant focus on R&D and our proprietary measuring standard, we can verify and deliver some the most impressive motion control performance metrics in the world, exactly what the semiconductor industry needs. Here are just a couple examples of the detailed feedback capabilities available:

Exposed linear encoders

Exposed linear encoders from HEIDENHAIN operate with no mechanical contact between the scanning head and the scale or scale tape.

- Accuracy grades down to ±0.5 µm

- Measuring steps of down to 0.001 µm (1 nm)

- Interpolation error: ±0.01 nm

Angle encoders

An encoder is classified as an angular encoder when the accuracy it better than ±5″ and has a line count above 10,000.

- Signal periods up to 360,000

- Accuracy down to ±0.4″

- Measuring steps: as fine as 0.00001° or 0.036″ (incremental) or 29 bits, i.e. approx. 536 million positions per revolution (absolute)

Need help figuring out how to control motion in a semiconductor application? We can help guide you and/or find the best components for what you’re trying to achieve.