February 3, 2020

ETEL expands popular CHARON2 motion platform

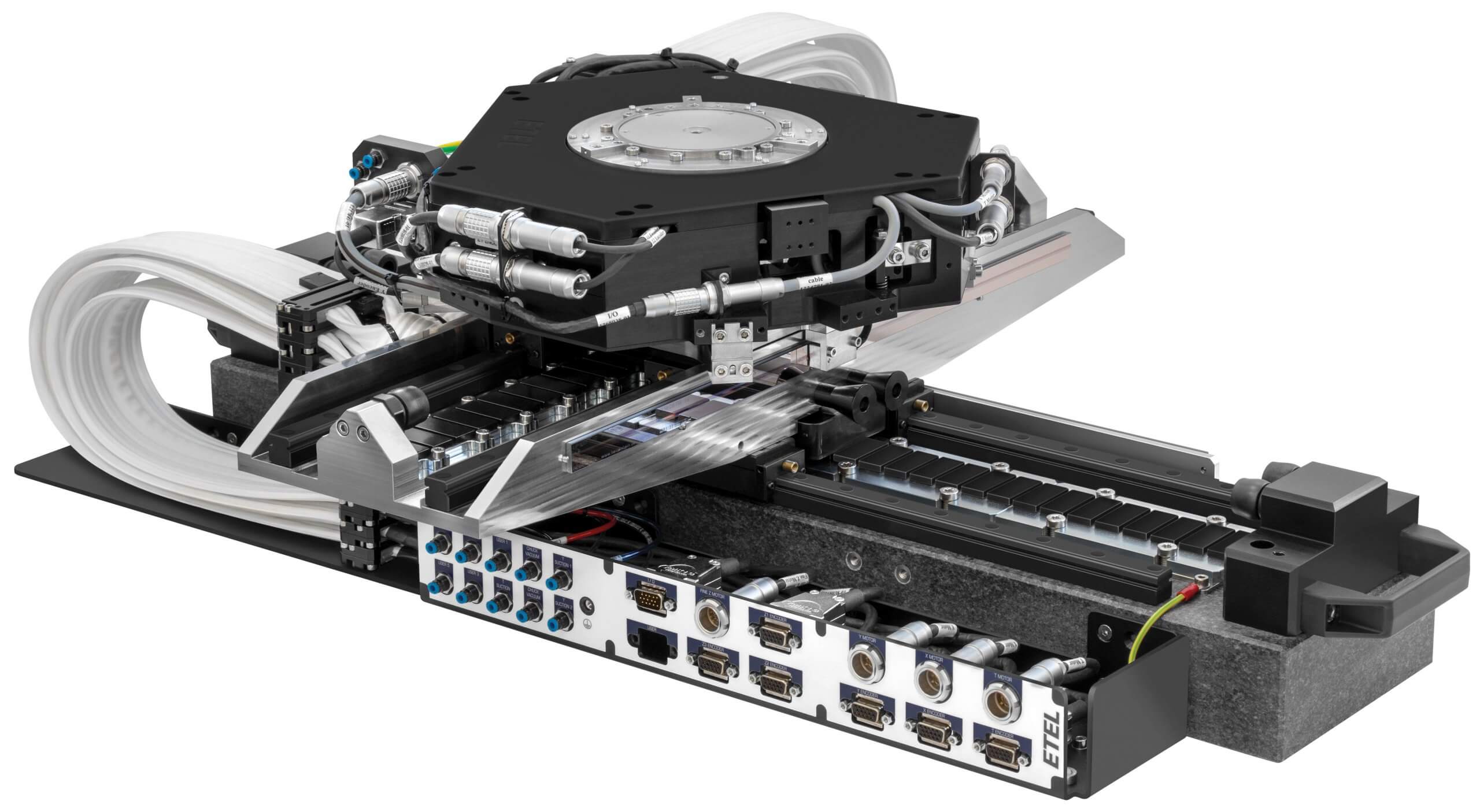

ETEL’s CHARON2 XYZ3TM Motion Platform System

SCHAUMBURG, IL (February 2020) – ETEL of the HEIDENHAIN Group has extended its motion systems product offering with the expansion to nine standard versions of CHARON2, its popular motion platform. The CHARON2 was originally designed in 2017 as an entry level platform to be flexible, scalable, modular and upgradable for semiconductor manufacturing applications. With these new additional configurations, the proven CHARON2 is now able to address any semiconductor use case as well as other markets with optimized cost, uniform performance and high reliability.

The CHARON2’s modularity starts as a standalone X-axis and can be upgraded to a complete motion system of up to seven axes with the inclusion of the Z3TM module for tip-tilt.

A total of nine standard configurations are now available with two electronic options for each allowing for a total of eighteen off-the-shelf products for OEMs to be able to cover any configuration needs. These multi-axis options will be compatible with future modules and options ensuring long term adaptability for semiconductor applications as well as other markets such as medical, pharmaceutical, material science, and optics and precision automation.

Each option of the CHARON2 has a position accuracy of up to ±1 µm level paired with excellent bidirectional repeatability between ±0.3 and ±0.4 μm. It is able to achieve a maximum performance of 1 m/s and accelerations ranging from 10 to 20 m/s2. These specifications along with ETEL’s long term expertise on direct drive technology ensures a machine life with low maintenance and high reliability, all within a compact footprint.

ETEL S.A. is based in Switzerland with exclusive North American distribution through HEIDENHAIN CORPORATION in Schaumburg, IL. As a leading international supplier of direct drive and motion control components and integrated systems, ETEL supports high tech industry with linear motors, torque motors, positioning stages, and motion controllers/systems. More ETEL information can be found here.

Contact:

Brian Zlotorzycki, Business Development Specialist, ETEL

847-755-5569

Media contact:

Kathleen Herrmann, Public Relations Manager

847-519-4702