Filter by topic

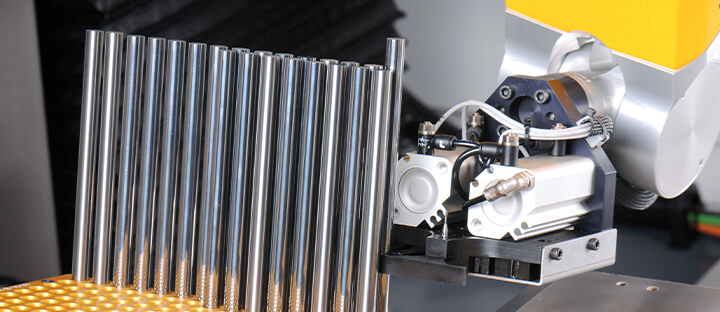

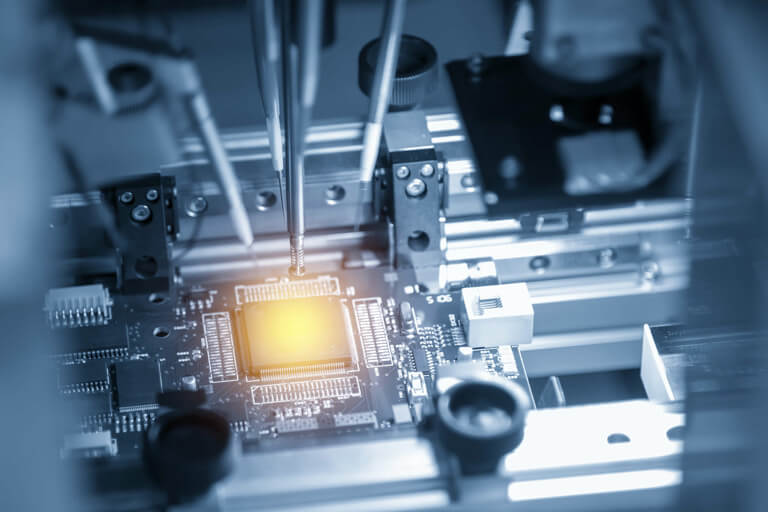

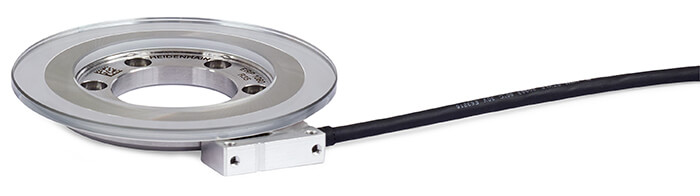

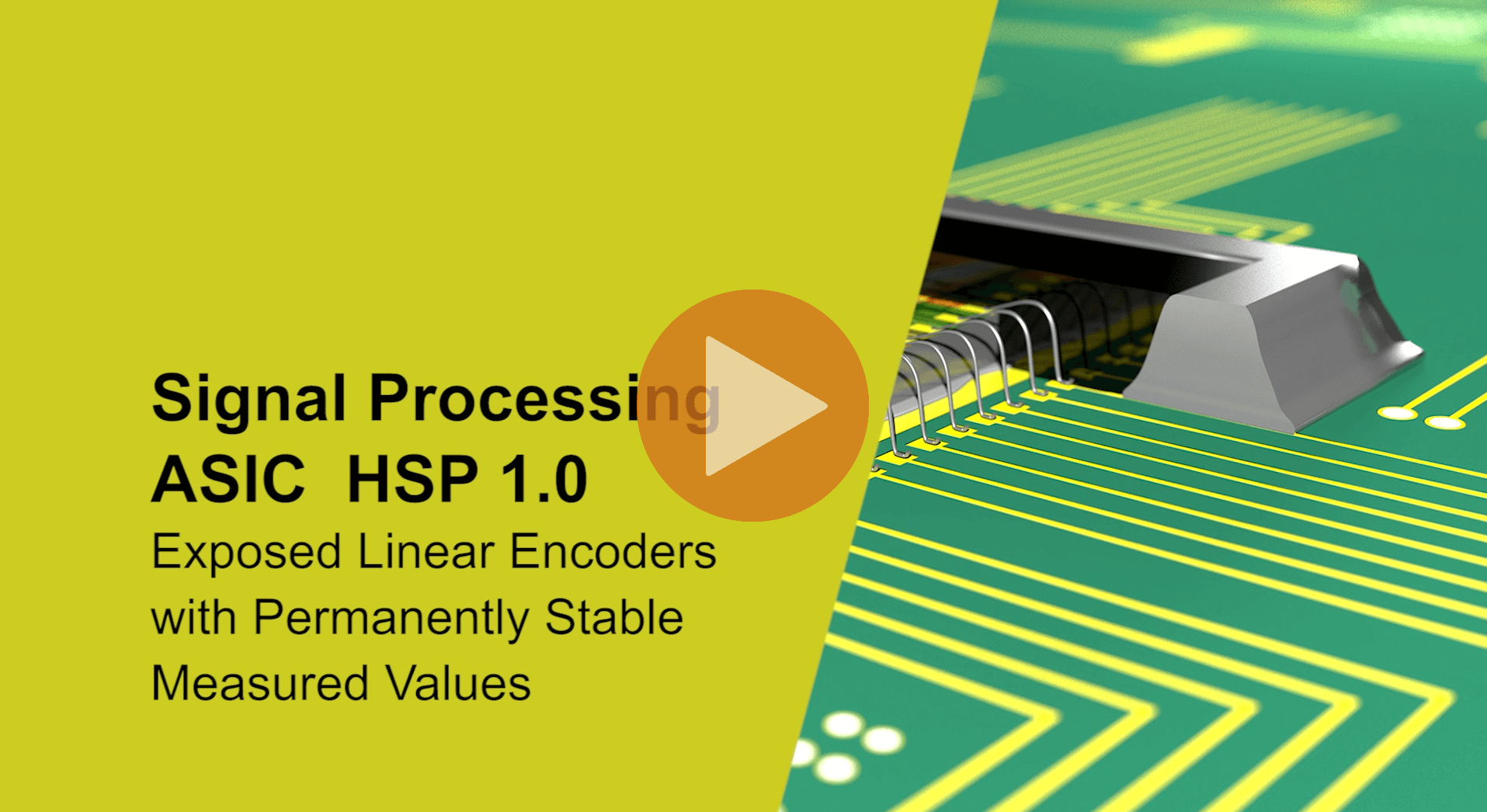

Semiconductor Manufacturing

Discover information to learn more about semiconductor manufacturing.

User portal

Strong brands for your applications

Sign up for our e-newsletter

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.