Filter by topic

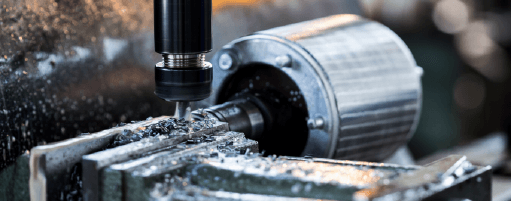

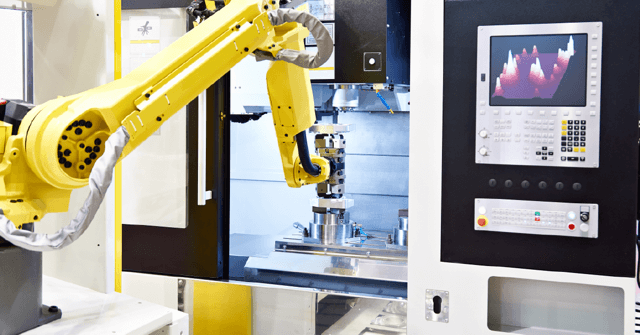

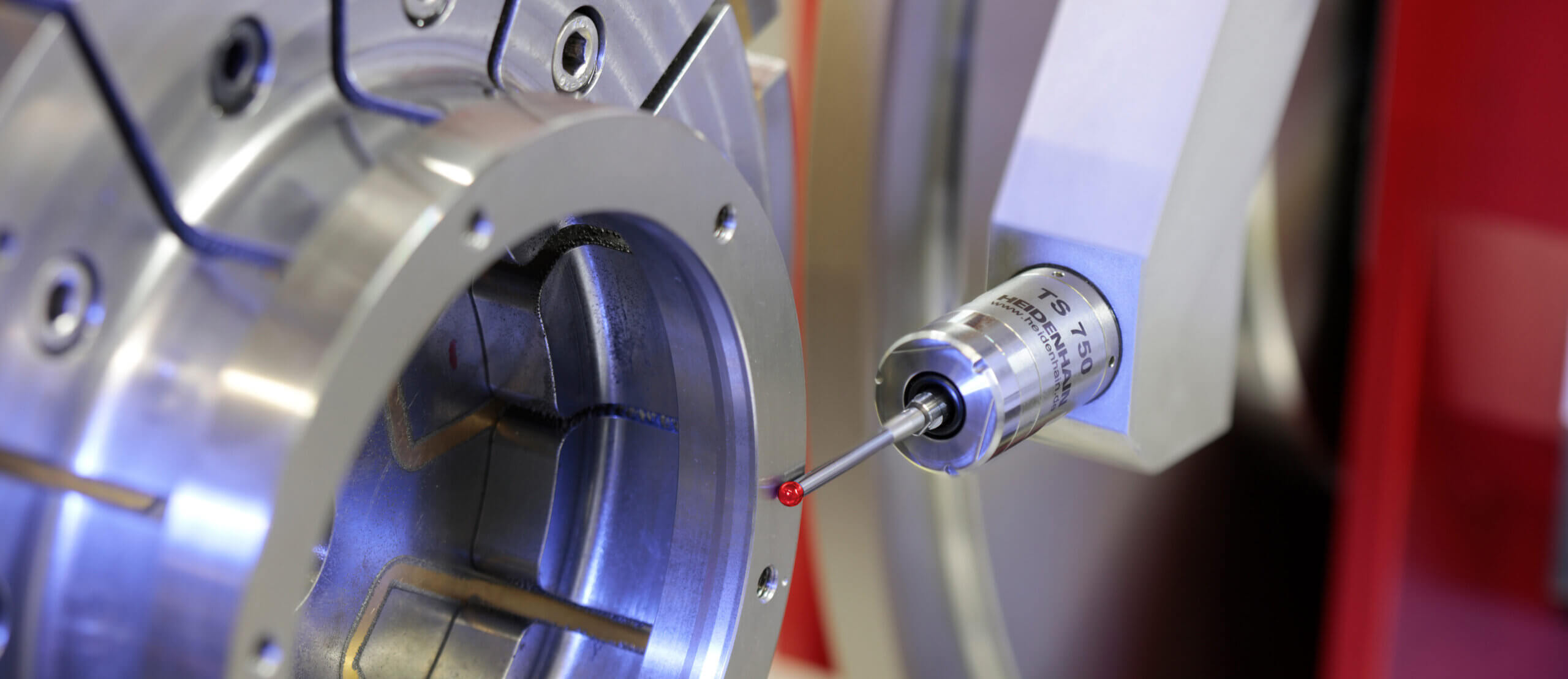

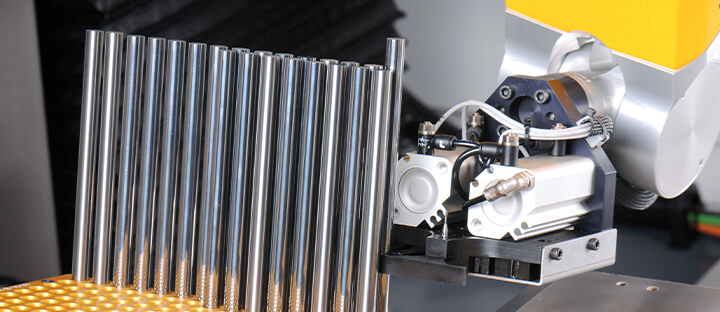

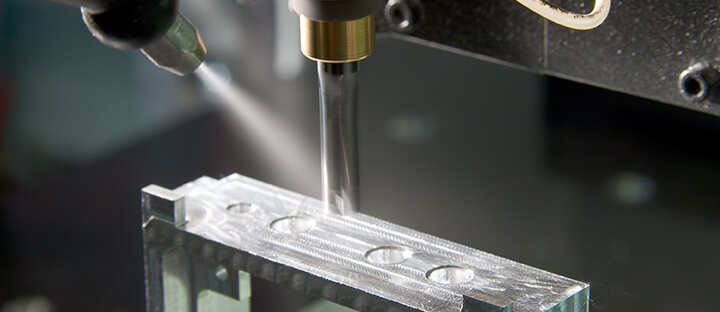

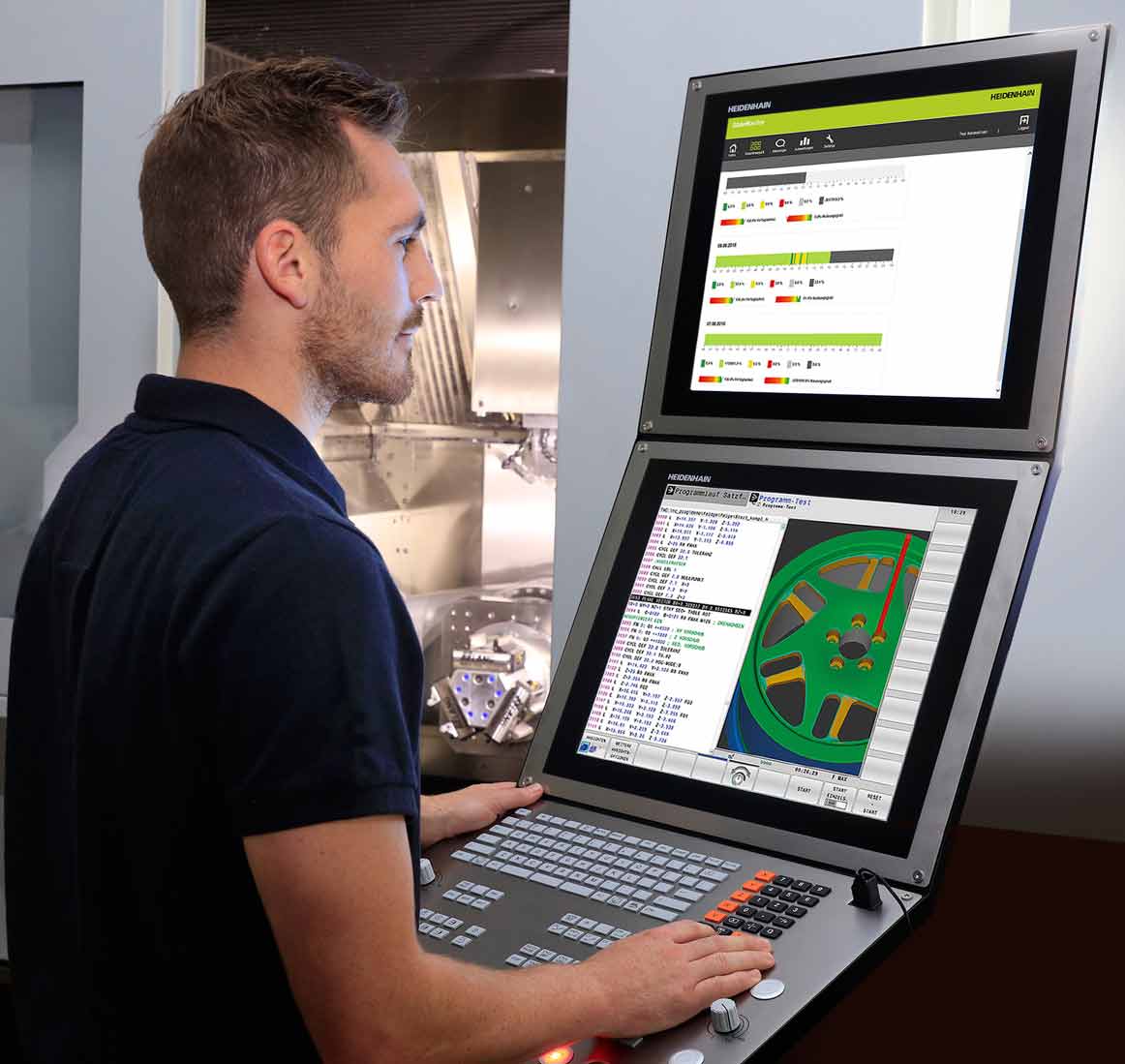

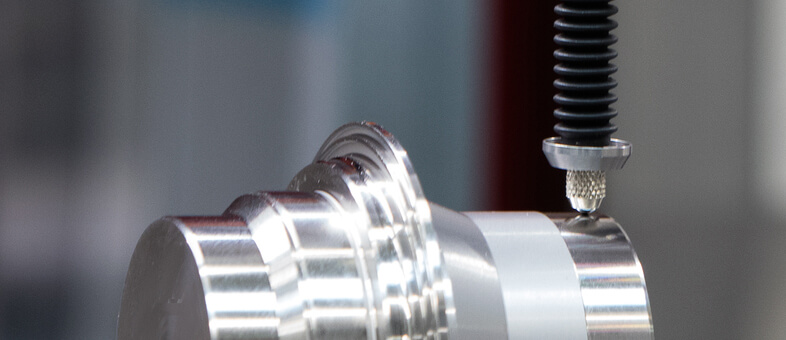

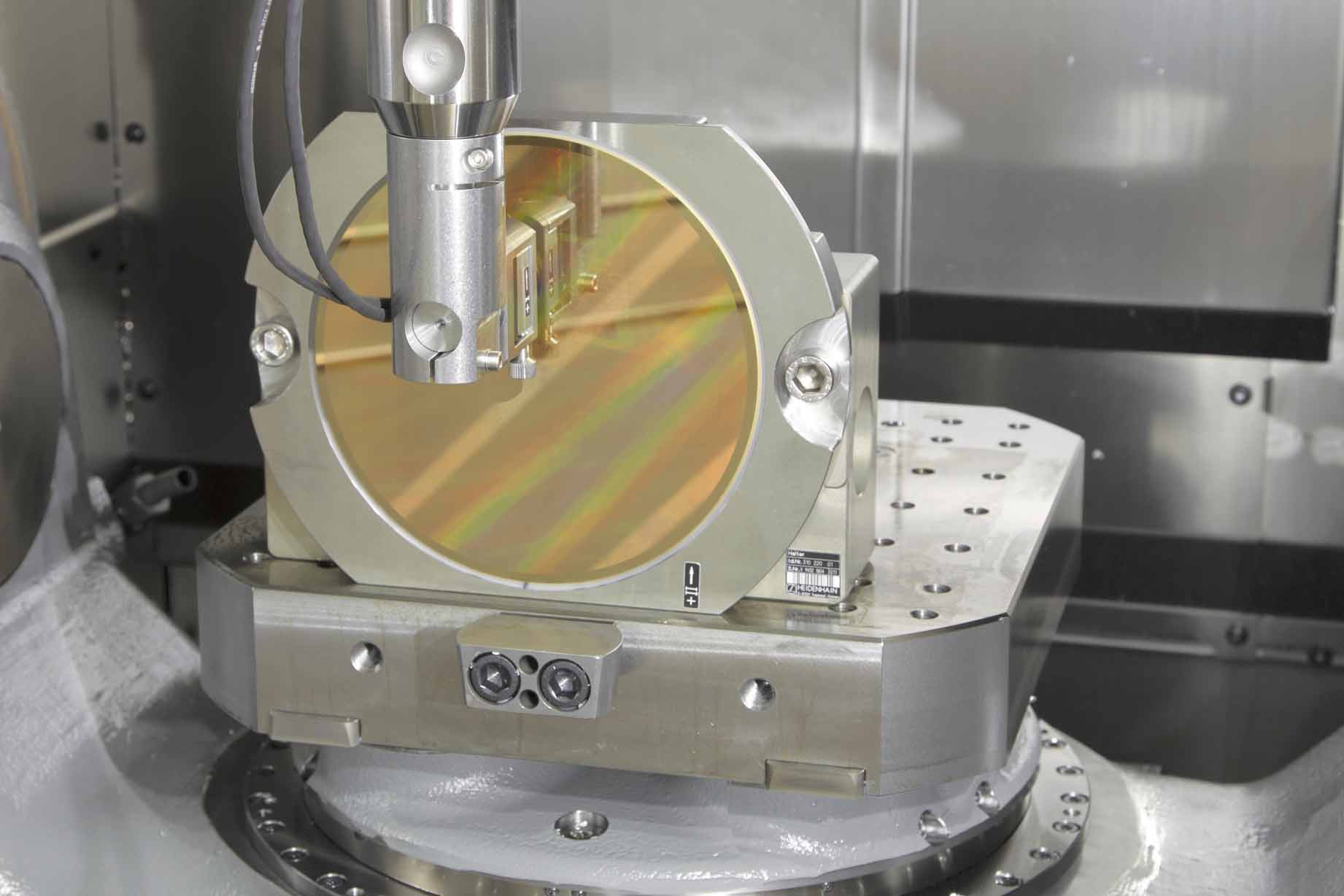

Machine Tool

Discover information to learn more about the machine tool industry.

User portal

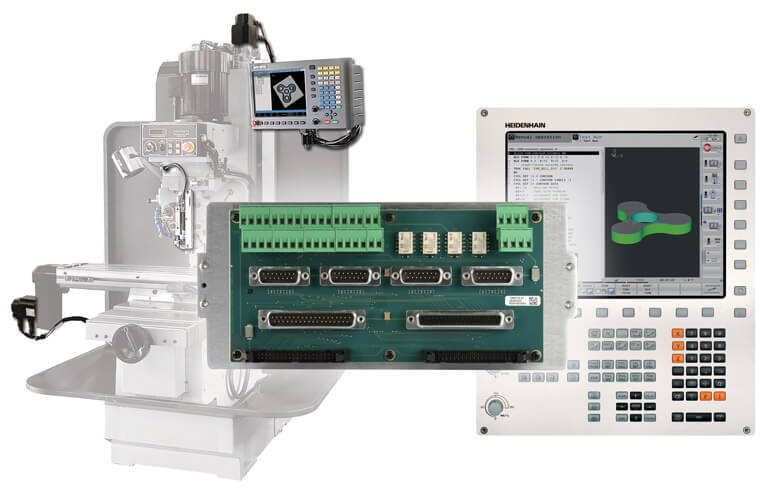

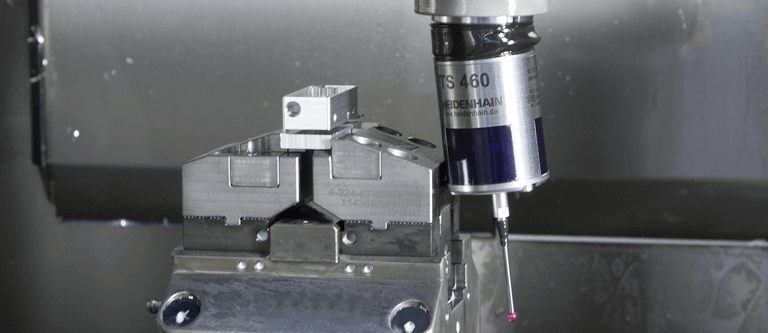

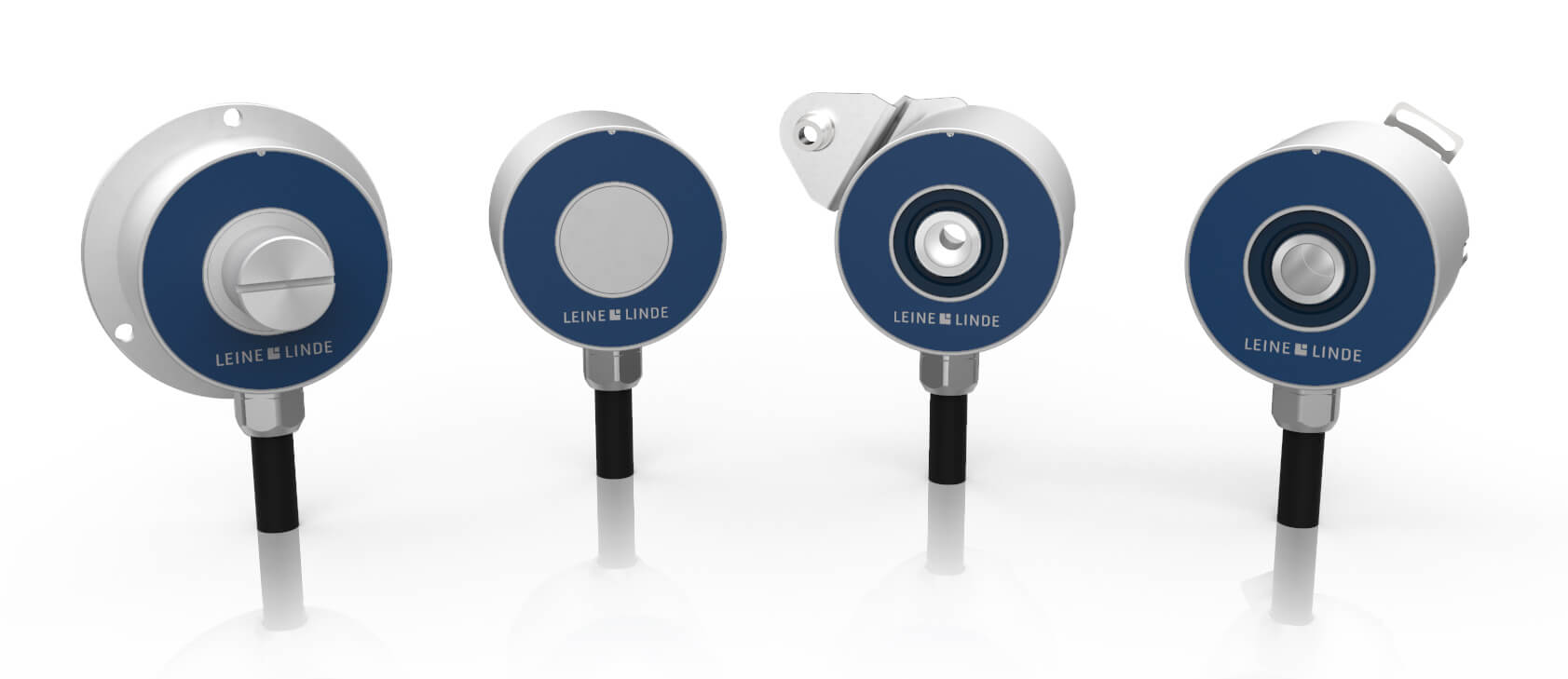

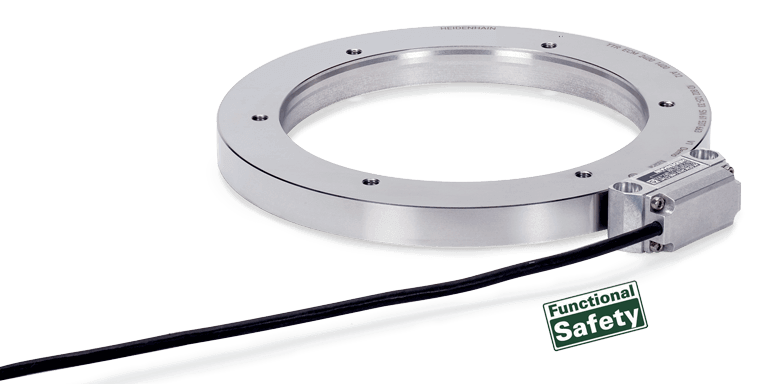

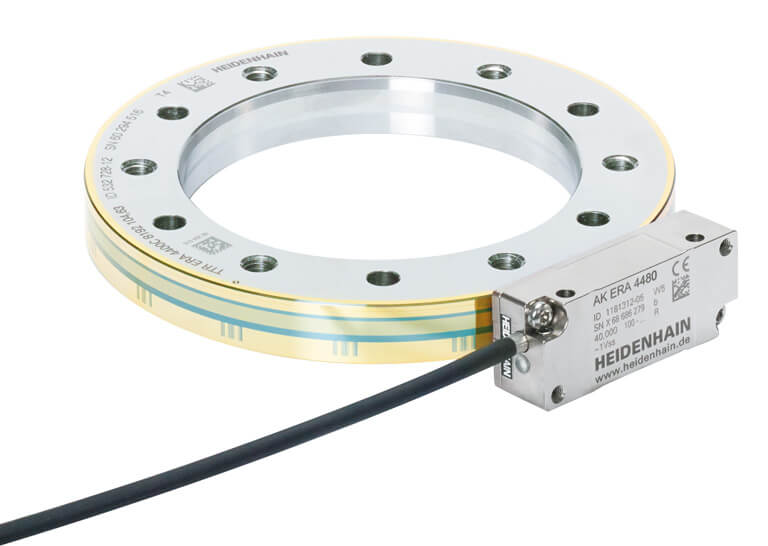

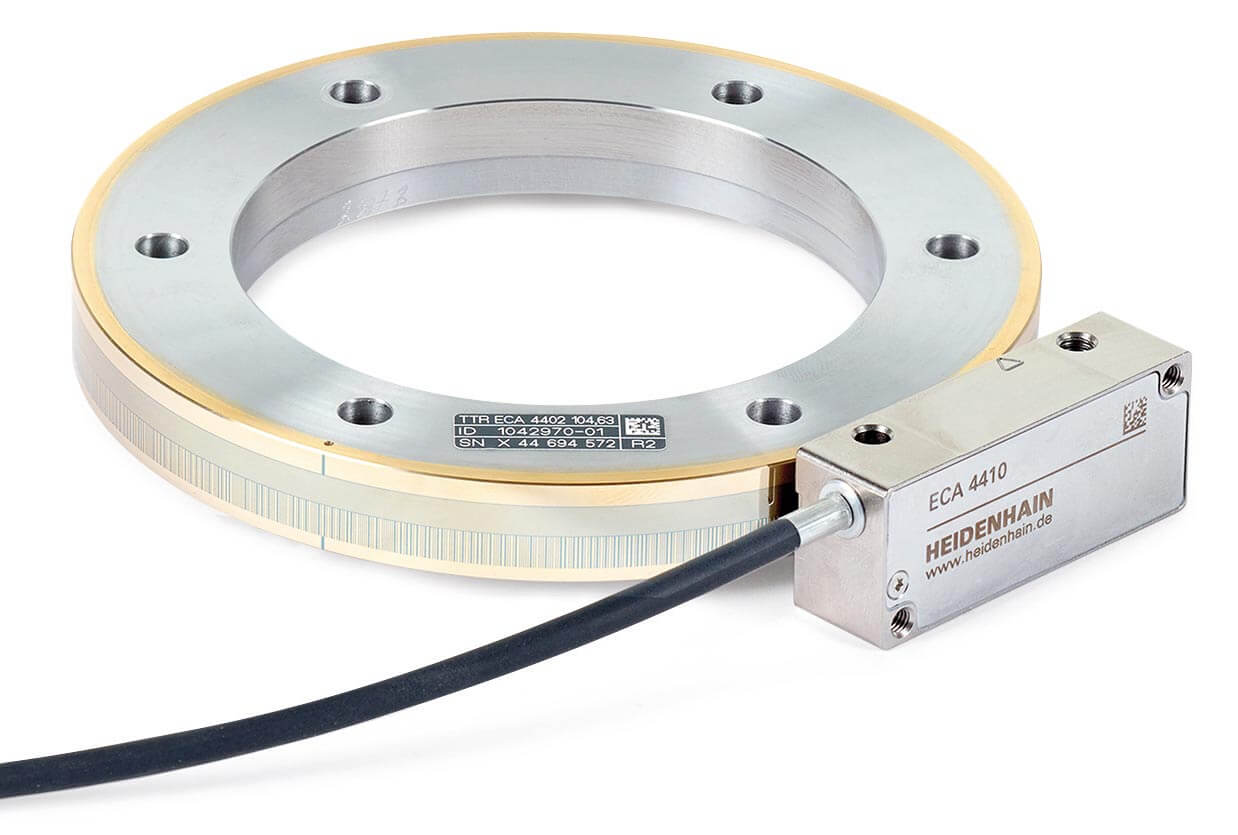

Strong brands for your applications

Sign up for our e-newsletter

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.