June 19, 2018

3 biomedical engineering trends that are saving lives

When it comes to biomedical engineering, the future is here, now. From unprecedented DNA sequencing capabilities to flawless robotic surgeries and other automated treatments, doctors and medical laboratories have more life-saving innovations at their disposal than ever before.

A common thread that enables many of these technologies? Incredibly precise motion feedback and control—and the advancement in this area continues to astonish. It’s thanks to ground-breaking innovations in linear encoders, linear motors, motion systems and microfluidics. And when the best of these work together, incredible things are possible.

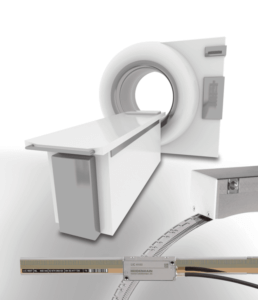

Radiation Treatment

Machines that treat patients for tumors with radiation inherently have complicate d, coordinated motion control. Guiding the radiation beams when the patient is on the table is critical, and any errors may damage cells that are intended to remain healthy. Since there is a radiation environment on the machine, communication between linear encoders and the control is of upmost importance and redundancy is needed.

d, coordinated motion control. Guiding the radiation beams when the patient is on the table is critical, and any errors may damage cells that are intended to remain healthy. Since there is a radiation environment on the machine, communication between linear encoders and the control is of upmost importance and redundancy is needed.

For this reason, HEIDENHAIN developed its encoder interface, ENDAT. ENDAT is a high speed serial interface that is RS 485-based and offers the fastest bi-directional communication protocol available. What caught the attention of biomedical engineers is a little known ENDAT function called CRC. CRC, or Cyclic Redundancy Check, is transmitted along with the position words from the encoder to the control. Basically, the CRC reports the number of bits transmitted to the control, and the control can then evaluate the number of bits and make a checksum. If the number of bits match, then everything is operating normally; however if the checksum does not match, then the ENDAT interface reports an error, which the control can then handle and take the proper steps needed for reliable motion control.

Laboratory Analysis

Laboratory analysis requires high throughput and exceptional accuracy—and it’s a careful choreography between linear encoders, motions systems and microfluidic biochips. If one doesn’t perform up to the highest standards, the results can be disastrous.

Drug testing machines, for example, typically use pipettes to distribute liquids to hundreds of tiny wells. Furthermore, these machines often operate overnight with little or no supervision. Anything less than flawlessly smooth motion can spill or misplace liquids and destroy data.

Repeatability is also critical—but can be a challenge as heat from the machine can cause small but consequential changes in the machine shape, and thus, its movement. Linear encoders that report the real position, versus a rotary encoder/ball screw setup, are more accurate; the latter can cause repeatability issues and even lead to the pipette array missing its targeted wells or causing a crash.

DNA sequencing machines are another lab automation technology that requires impeccable precision. They employ flowcells, which are or what engineers call lab-on-a-chip, and may contain several billion micro wells. Motion system cameras must detect colors from these tiny wells at a sub-micron level. In these fine resolution applications, the interpolation error of the encoder (or sub-divisional error) is very important. When the encoder signal periods are electronically subdivided to gain more resolution, errors can happen resulting in faulty data collection from the camera. HEIDENHAIN linear encoders are designed to have the lowest interpolation error on the market and are highly sought after in this regard. One encoder, the LIP 200, has interpolation error at +/- 1 nanometer. This kind of encoder helps to ensure the stability of the image required to evaluate the colors of the wells on the flowcell.

DNA sequencing machines are another lab automation technology that requires impeccable precision. They employ flowcells, which are or what engineers call lab-on-a-chip, and may contain several billion micro wells. Motion system cameras must detect colors from these tiny wells at a sub-micron level. In these fine resolution applications, the interpolation error of the encoder (or sub-divisional error) is very important. When the encoder signal periods are electronically subdivided to gain more resolution, errors can happen resulting in faulty data collection from the camera. HEIDENHAIN linear encoders are designed to have the lowest interpolation error on the market and are highly sought after in this regard. One encoder, the LIP 200, has interpolation error at +/- 1 nanometer. This kind of encoder helps to ensure the stability of the image required to evaluate the colors of the wells on the flowcell.

Meanwhile, technologies from ETEL and IMT also contribute to faster, more accurate lab automation. ETEL motion control solutions are scalable and range from components such as motors and electronics all the way to complete motion systems; their distributed architecture can handle multiple axes simultaneously. ETEL linear motors provide high acceleration, a patented cogging-free motion and exceptional thermal efficiency. Finally, IMT offers flexible process offerings that enable microfluidic solutions in glass, the benefits of which include excellent chemical, mechanical, and optical properties; outstanding surface properties; and cost-efficiency when scaling from prototyping to mass manufacturing.

Robotic Surgery

Several years ago, surgery by robot might have seemed like science fiction. But today it’s commonplace. In fact, 80 percent of prostate surgeries done in the U.S. today are done with robotic-assist surgery robots. Many surgery robots require redundancy in motion control components to ensure absolute accuracy. The aforementioned ENDAT interface and several linear encoders in the HEIDENHAIN line are Functionally Safe, with various mechanical options that can fulfill the need of surgery robot design.

Another common requirement in surgery robots: the ability to drill and measure  distances at the same time. Here accuracy with respect to the national standard is important, for obvious reasons: incorrect measurements can mean life or death. HEIDENHAIN’s high-accuracy encoders, both linear and angular are engineered to the highest standards. And thanks to our smooth calibration charts with no error spikes, biomedical engineers can be sure they’re choosing a component that will live up to their requirements.

distances at the same time. Here accuracy with respect to the national standard is important, for obvious reasons: incorrect measurements can mean life or death. HEIDENHAIN’s high-accuracy encoders, both linear and angular are engineered to the highest standards. And thanks to our smooth calibration charts with no error spikes, biomedical engineers can be sure they’re choosing a component that will live up to their requirements.

To learn more about HEIDENHAIN biomedical design components, contact us today.