Smarter measuring, better machining: the HEIDENHAIN touch probe advantage

Serving our communities: HEIDENHAIN volunteers in action

HEIDENHAIN CORPORATION and Acu-Rite Solutions to exhibit at EASTEC 2025

HEIDENHAIN CORPORATION to exhibit at AUTOMATE 2025

Empowering precision: How Rennscot MFG achieves excellence with HEIDENHAIN

Empowering the future of manufacturing

HEIDENHAIN CORPORATION to exhibit at MD&M West 2025

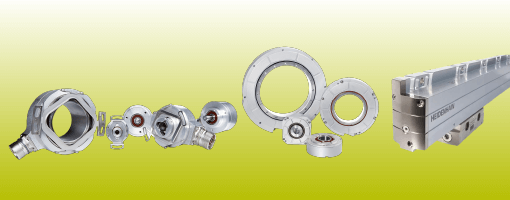

How to optimize your encoder system

HEIDENHAIN CORPORATION to exhibit at PRI 2024

Choosing the right encoder for your application

Filter by topic