ETEL direct drive linear and torque motors

- One of the most comprehensive ranges of direct drive linear and torque motors in the industry

- Long-term benefits of direct drive technology include lack of maintenance, dynamic capabilities and compact form factor

- ETEL’s direct drive motors feature an industry-recognized log-cogging design

- Special construction enables an exceptional force density and unparalleled thermal efficiency

- Customers benefit from deep expertise in direct drive systems during the design phase, installation, ramp-up and beyond

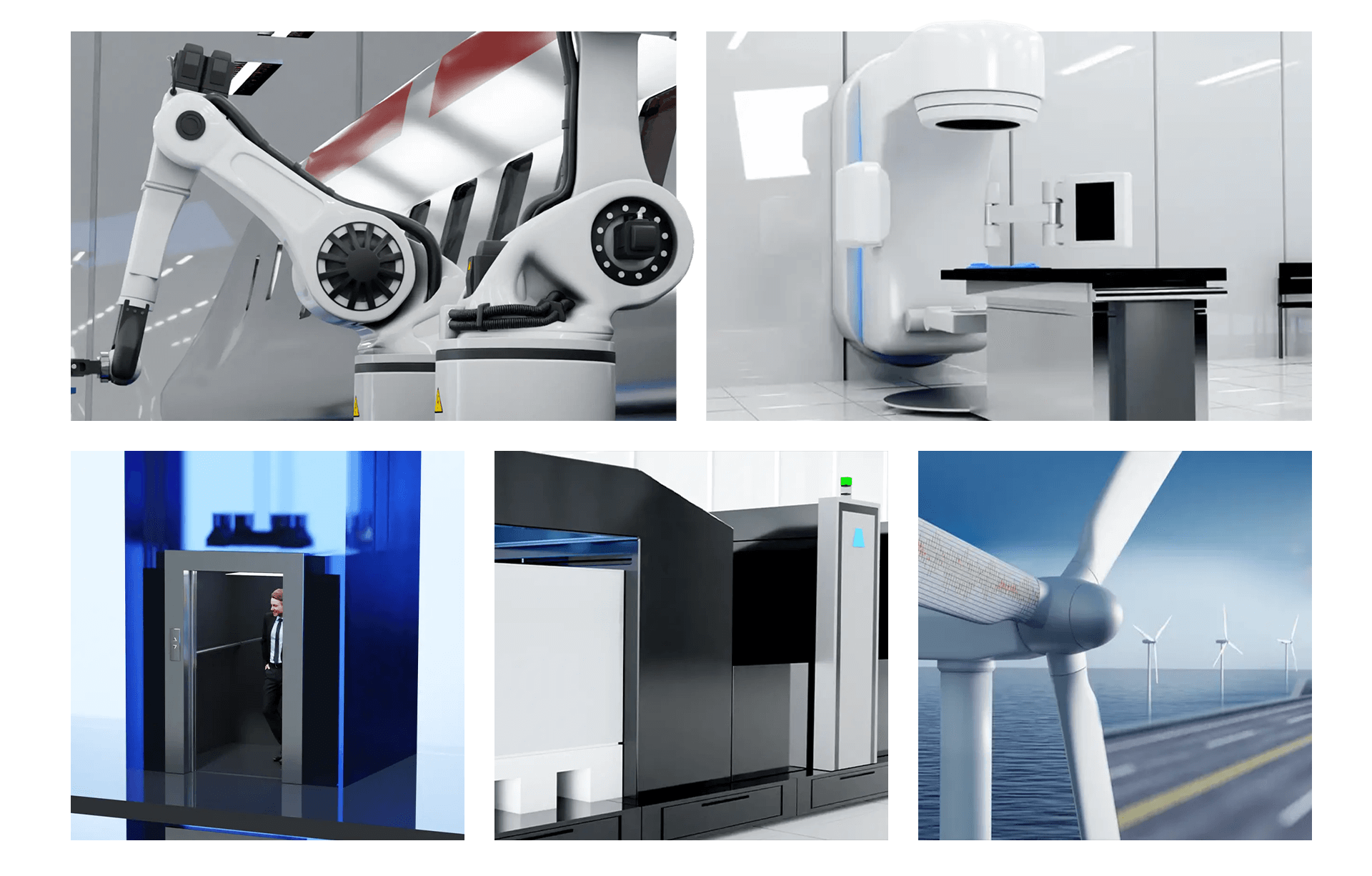

ETEL motion systems

- Our expertise in magnetic designs, bearing technology, metrology concepts, motion control architecture and materials make us the supplier of choice for advanced mechatronics

- Standalone products include short-stroke actuators, rotary axes, ZT combined modules, stacked/split systems, gantry platforms, planar platforms and electronic controllers

- Motion system platforms optimally combine motors, bearings, feedback, controls and isolations systems into the finest stage on the market

- Forty years of expertise and direct drive expertise combine to create the most effective linear motor operation possible and ideal solutions for the electronic industry

Resources

ETEL Product Overview

Since its founding in 1974, ETEL has grown to become a leading supplier of high performance motion control components and complete motion platforms.

Download PDFLinear Motors

Over the last 20 years, direct drive linear motors have provided significant performance improvements in numerous applications.

Download PDFTorque Motors

Over the last 30 years, direct drive torque motors have provided significant performance improvements in numerous high-tech industries.

Download PDFFAQs

Stories

Related news

Smarter measuring, better machining: the HEIDENHAIN touch probe advantage

In machining, we understand that every micron counts and every minute matters, and the ability to measure and inspect ...

Serving our communities: HEIDENHAIN volunteers in action

At HEIDENHAIN CORPORATION, we’re committed to creating life-changing technology through engineering excellence—but we also believe in making a difference ...

Empowering precision: How Rennscot MFG achieves excellence with HEIDENHAIN

At HEIDENHAIN, we are dedicated to empowering manufacturers with advanced control technology that drives precision, efficiency, and growth. Rennscot ...