TNC 640 contouring control

The smart solution for demanding requirements

- 24 control loops (22 with functional safety), including up to 4 spindles

- Version with multi-touch screen

- Milling, turning, and grinding operations

- User-friendly programming in HEIDENHAIN Klartext or with G codes

- Extensive machining and touch-probe cycle packages

- Fast block processing time (0.5 ms)

- High-end performance for perfect surfaces and exceptional accuracy

- Dynamic collision monitoring for greater safety and reliability

Complete machining

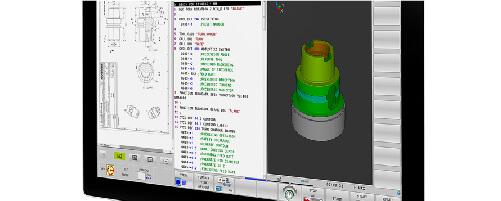

The TNC 640 features an extensive package of cycles for milling, drilling, boring, grinding, and turning operations. It also provides special cycles for complex applications such as interpolation turning and hobbing. All of this functionality can be programmed with Klartext functions and cycles.

Optimal machining

The OCM option optimizes roughing processes, using special trochoidal milling cycles to machine any contour with high efficiency. Productivity is significantly increased, while tool wear is considerably reduced. The optimal cutting data are determined by an integrated cutting-data calculator.

Exceptional availability

Dynamic Collision Monitoring (DCM) monitors the work envelope during all operating modes and stops traversing movements before a pending collision. DCM therefore allows optimal use of the machine envelope, preventing machine damage and costly downtime.

Efficient workstation

Extended Workspace seamlessly brings PCs and external applications to the control’s screen. The comfort version adds an additional display to the work area, while the compact version offers an extra application window inside the 24-inch widescreen.

Dynamic Efficiency

The Dynamic Efficiency package of functions is well matched to the requirements of roughing operations. Various functions offer enormous potential for optimizing process reliability, machining time, and idle time, making production more effective, stable, and predictable.

Dynamic Precision

Dynamic Precision includes multiple functions that improve the contouring accuracy of machine tools, even during high feed rates and complex movements. Precise parts can be efficiently manufactured in short machining times without manual rework.

Application-oriented design

Click the plus signs to learn more about the product.

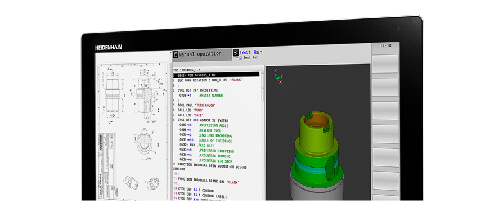

The intuitive and clearly structured user interface make simple operation and optimal orientation possible

Gesture control makes it very easy to zoom and rotate simulation graphics as well as to navigate through programs, tables, or menus

The well-structured operating panel is systematically divided into function groups and features meaningful key symbols

Lot size 1 with process reliability

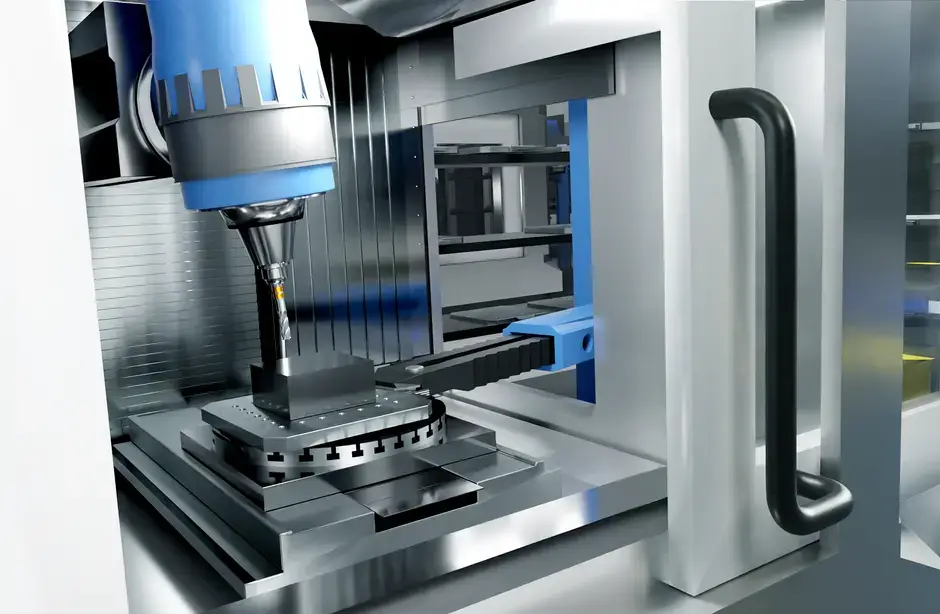

The TNC 640 defines the high-end spectrum of control technology within its field. Along with complex milling operations, it also enables combined milling, turning, and grinding operations, making it particularly well suited for HSC and 5-axis simultaneous operations, including on fully automated machining centers. The TNC 640 stands for perfect surface quality, exceptional accuracy, and very short machining times, combined with shopfloor-friendly operation and programming. Its technologically pioneering functions ensure a high level of precision, efficiency, and process reliability starting with lot size 1.

Easy connectivity

Easy data usage, time-saving workflows, and transparent processes: Connected Machining enables optimal connection to digital job and data management solutions in a manufacturing context. With the Connected Machining package of functions, HEIDENHAIN controls can be perfectly integrated into process chains through future-ready digital interfaces and flexible operating designs, thus optimizing the transfer of knowledge within your company. Connected Machining incorporates HEIDENHAIN controls into the purely digital job management landscape of a production network and places the user at the center of the digital job management process.

Connected Machining delivers:

- Easy data usage

- Time-saving workflows

- Transparent processes

Easy entry into automation

The automation possibilities for machine tools are wide-ranging and depend on a variety of factors. The HEIDENHAIN Automation Solution is an individualized modular package made up of different hardware and software products. The package’s software delivers intuitive operation to users, who can implement seamless tool and workpiece movements without extensive training. Machine manufacturers and automation providers can adapt the user interface to their needs and add their own operating functionality.

The key benefits at a glance:

- Intuitive, easy-to-operate user interface

- Universal data interfaces to all common machine tool controls

- User admin function for preventing improper operation