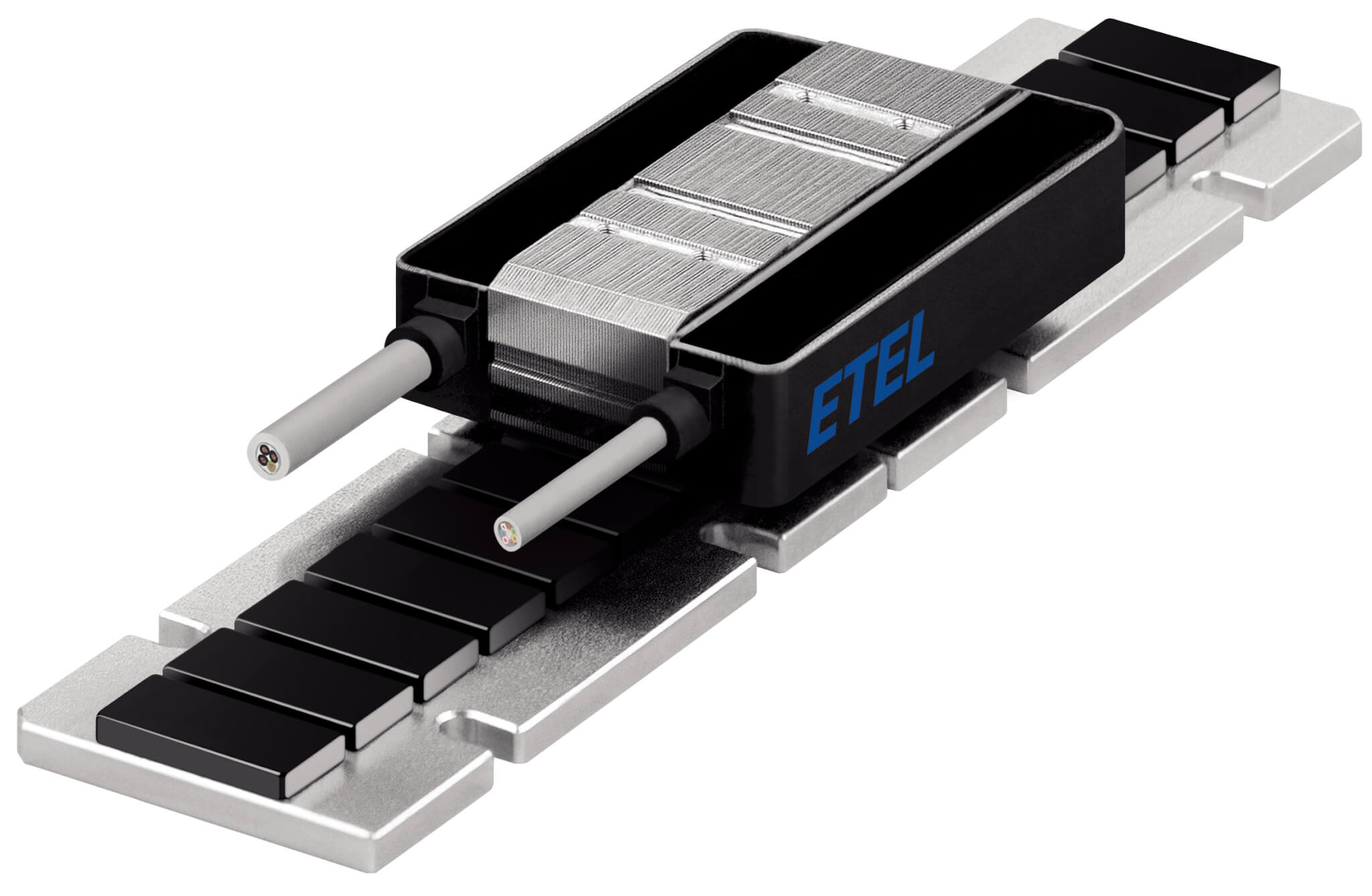

ETEL direct drive linear and torque motors

- One of the most comprehensive ranges of direct drive linear and torque motors in the industry

- Long-term benefits of direct drive technology include lack of maintenance, dynamic capabilities and compact form factor

- ETEL’s direct drive motors feature an industry-recognized log-cogging design

- Special construction enables an exceptional force density and unparalleled thermal efficiency

- Customers benefit from deep expertise in direct drive systems during the design phase, installation, ramp-up and beyond

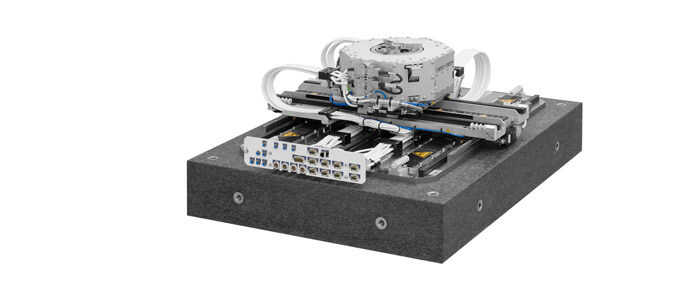

ETEL motion systems

- Our expertise in magnetic designs, bearing technology, metrology concepts, motion control architecture and materials make us the supplier of choice for advanced mechatronics

- Standalone products include short-stroke actuators, rotary axes, ZT combined modules, stacked/split systems, gantry platforms, planar platforms and electronic controllers

- Motion system platforms optimally combine motors, bearings, feedback, controls and isolations systems into the finest stage on the market

- Forty years of expertise and direct drive expertise combine to create the most effective linear motor operation possible and ideal solutions for the electronic industry

Resources

ETEL Product Overview

Since its founding in 1974, ETEL has grown to become a leading supplier of high performance motion control components and complete motion platforms.

Download PDFLinear Motors

Over the last 20 years, direct drive linear motors have provided significant performance improvements in numerous applications.

Download PDFTorque Motors

Over the last 30 years, direct drive torque motors have provided significant performance improvements in numerous high-tech industries.

Download PDFFAQs

Stories

A Great One-Two Punch

With the need for high-quality contour surface milling on the rise in manufacturing, this large machine tool builder based in the U.S. has met that challenge and is making an impact in the industries that need it most. Welcome TARUS.

Read more

An ultra-precise waterjet cutting machine for tile and stone

Did you know that multiple HEIDENHAIN components and systems, including HEIDENHAIN’s iTNC 530 contouring control, are critical components of innovative ultra-precise waterjet cutting machines? Because an ultra high-pressure waterjet machine’s ability to erode and cut through stone or metal is highly dependent on a smooth, consistent velocity, its measurement and feedback components must be reliable and in sync.

Read moreRelated news

Innovating medical imaging and radiotherapy: The ETEL advantage

As part of the esteemed HEIDENHAIN family of brands, ETEL is revolutionizing the way we build medical imaging and ...

Q&A: Overcoming the challenges of semiconductor manufacturing

In 2022, we spoke with Peter Suliga, Director of Eastern Sales for HEIDENHAIN CORPORATION, about the state of the ...

Understanding & choosing the right tool breakage system for your operations

In machining operations, tool breakage is an ever-present challenge. However, thanks to technological advancements, the issues breakage used to cause ...