Wind energy

Optimized for certification, installation and efficient operation on everything from the rotor blades, gearbox and generator to the pitch and azimuth system:

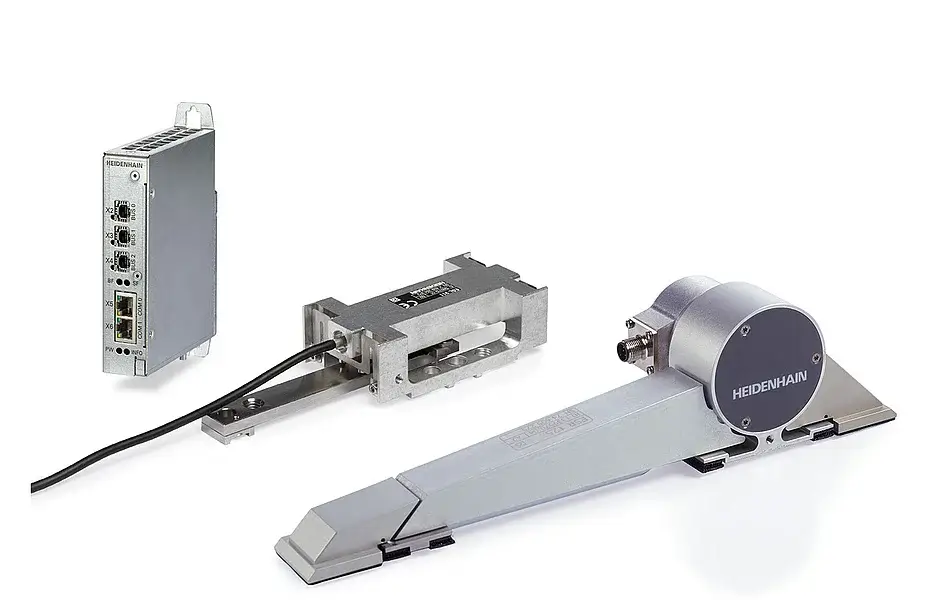

Discover encoders and sensors from HEIDENHAIN and its brands AMO, LEINE LINDE and LTN, designed for the rigorous requirements of wind turbines.

Wind power is one of the main pillars in the transition from fossil fuels to renewable energy. Achieving renewable energy goals requires more than a mere increase in the number of wind turbines. Their service life and performance must be optimized as well. Encoders, sensors and slip rings support this optimization throughout the manufacturing, operating and maintenance processes by delivering high-accuracy position, speed and load data for a wide range of wind-turbine components.

Solutions for wind turbines

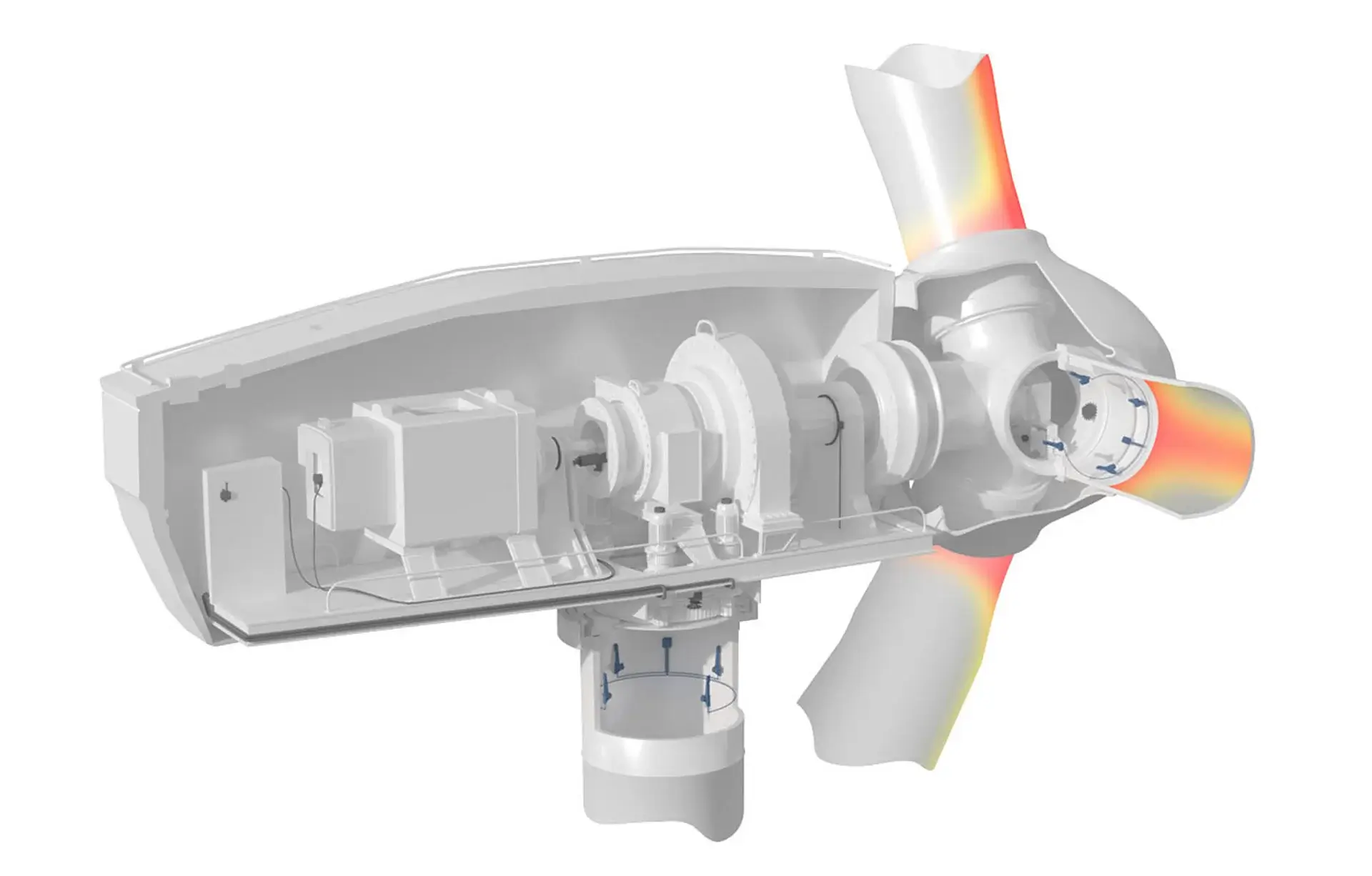

Wind turbines may look similar on the outside, but the way they generate power behind the walls of their nacelle varies.

Wind turbines equipped with a gearbox can leverage the many benefits of a high-speed generator. These generators are compact and rotate much faster than the rotor. The results are greater efficiency and an electrical frequency that matches the power grid.

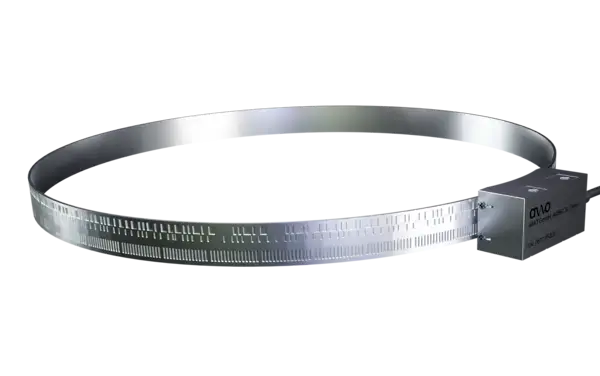

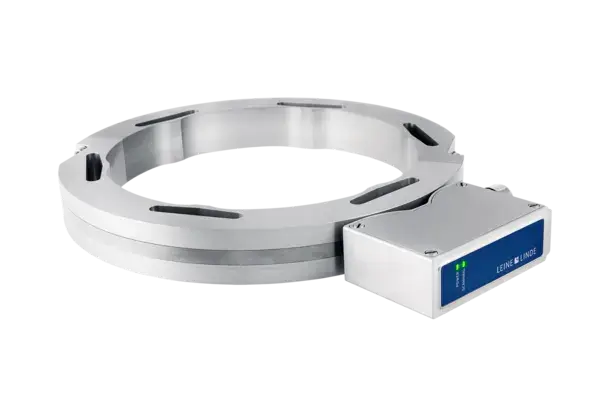

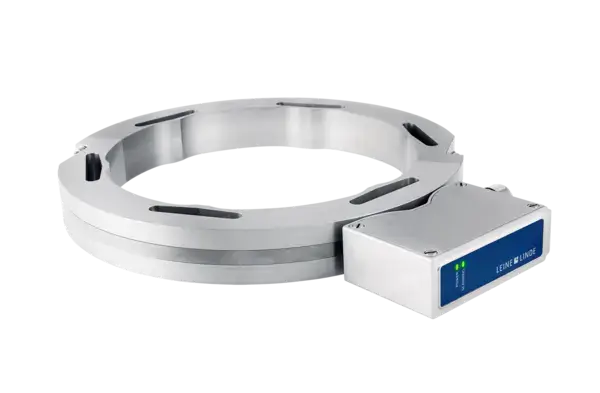

Wind turbines without a gearbox are more compact and contain fewer moving parts. But these benefits are offset by an expensive ring generator requiring ever greater weight for higher performance. Even for these generators, we provide reliable and easy-to-install modular encoders with very large diameters.

To discover sensors, encoders and slip rings designed for geared and gearless wind turbines, explore the products from HEIDENHAIN, AMO, LEINE LINDE and LTN below.

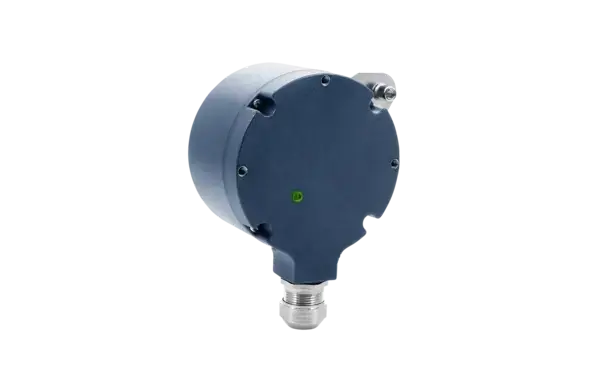

Encoders for measuring the rotational speed and position of generators

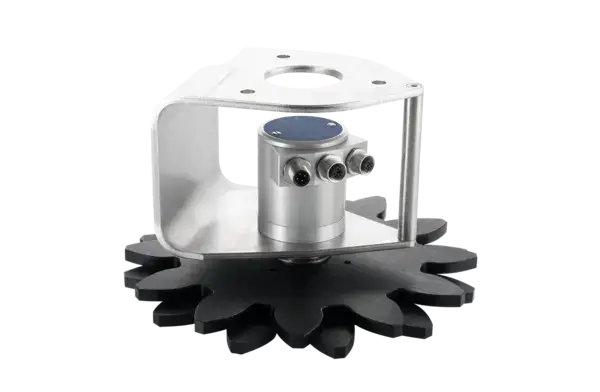

Encoders for measuring rotor speed and position

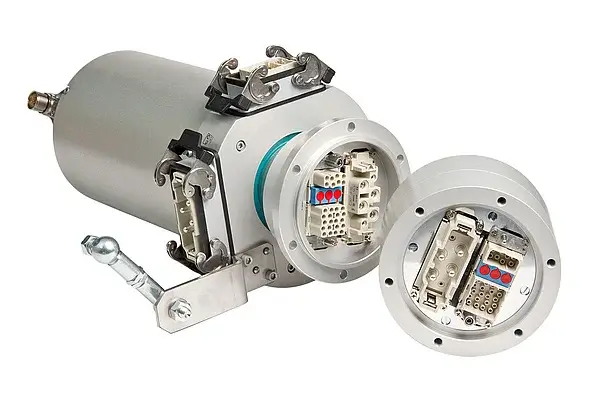

Slip rings for transmitting data, power and signals

Encoders for blade azimuth and pitch system motors

Encoders for measuring the nacelle and rotor-blade positions

Sensors for measuring loads on the tower, bed plate and rotor blades

Optimal performance for wind turbines

In order to maximize the efficiency and service life of a wind turbine, the control system needs reliable, real-time data about vibrations and structural loads acting on the tower, bed plate and rotor blades. Collecting this information as it unfolds in real time makes it possible to integrate active load control strategies and monitoring functions into the control system.

The benefits are significant:

- Longer service life

- Less maintenance

- Higher energy yields

- Lower structural component costs

The components of this system are characterized by the following:

- Unique combination of resolution and measuring range

- Good signal-to-noise ratio

- Simple installation and start-up

- Stable measurements over long time periods