Linear and angle encoders measure motion directly within a closed loop control system. Digital readouts for manually operated machine tools greatly simplify precision machining thanks to their numerous practical functions and cycles.

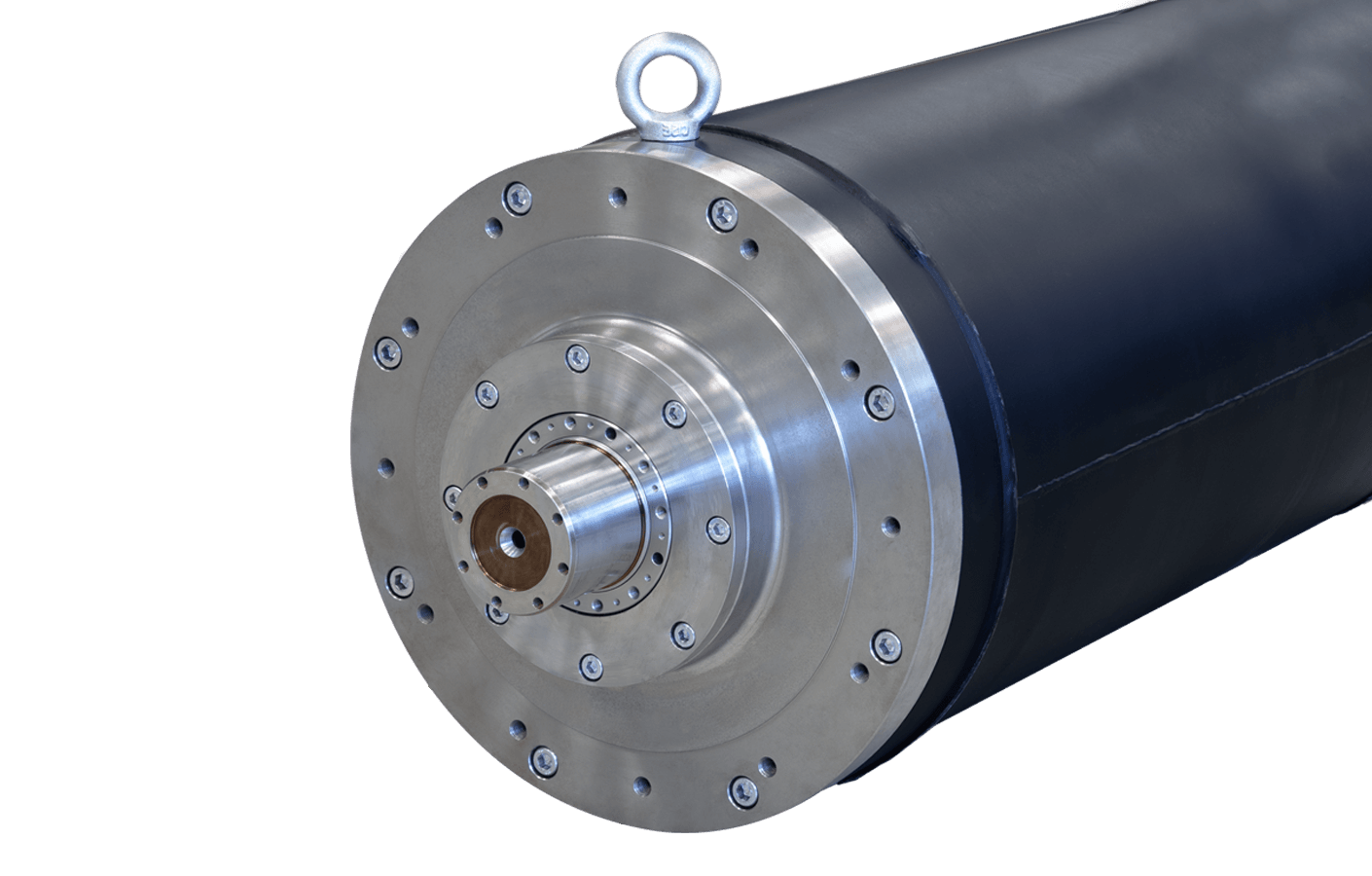

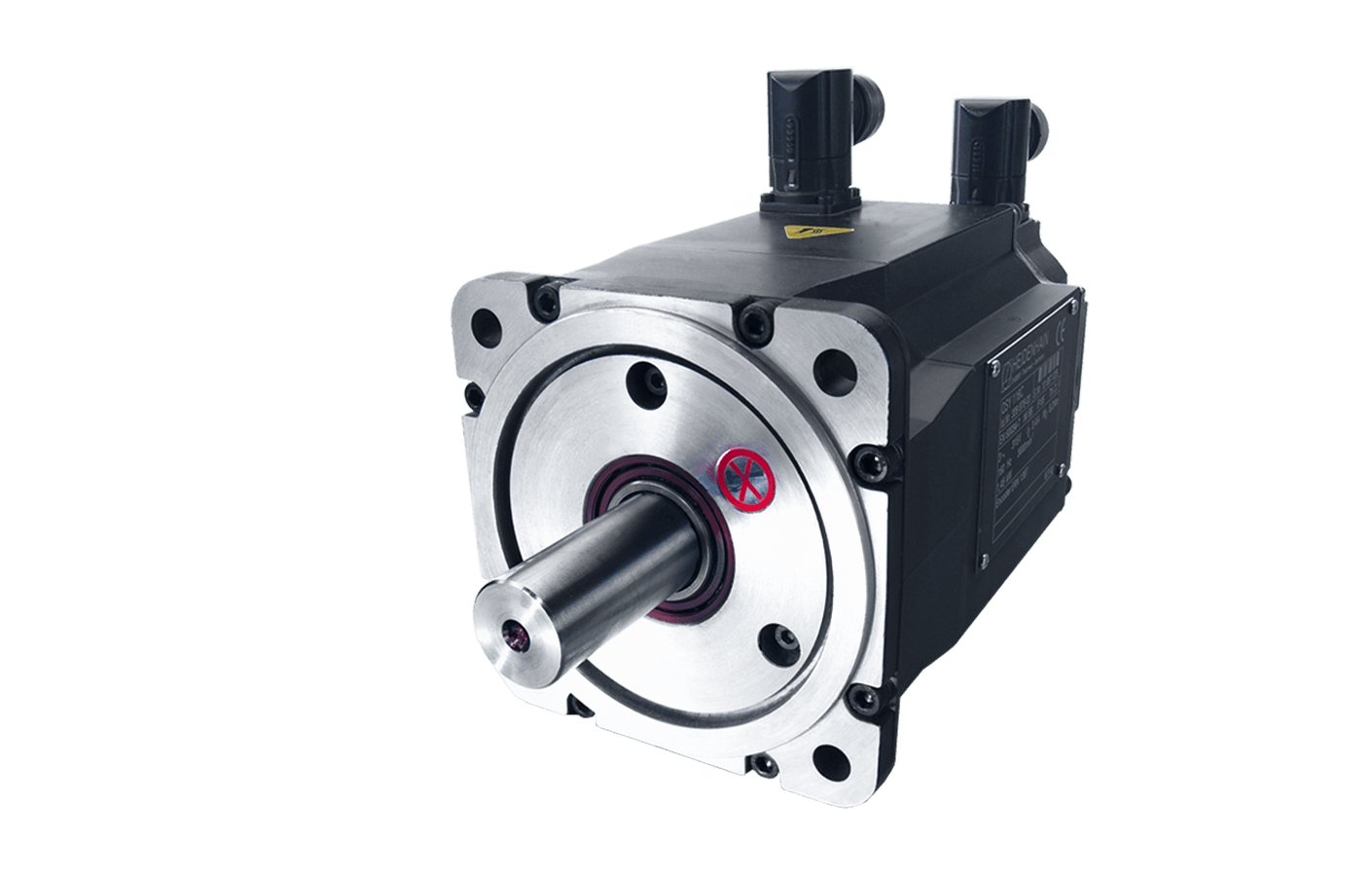

The new Gen 3 drives are designed to meet the requirements of lathes, providing state-of-the-art interface technology, excellent performance specs, and very high controller performance. HEIDENHAIN and ETEL also offer suitable motors.

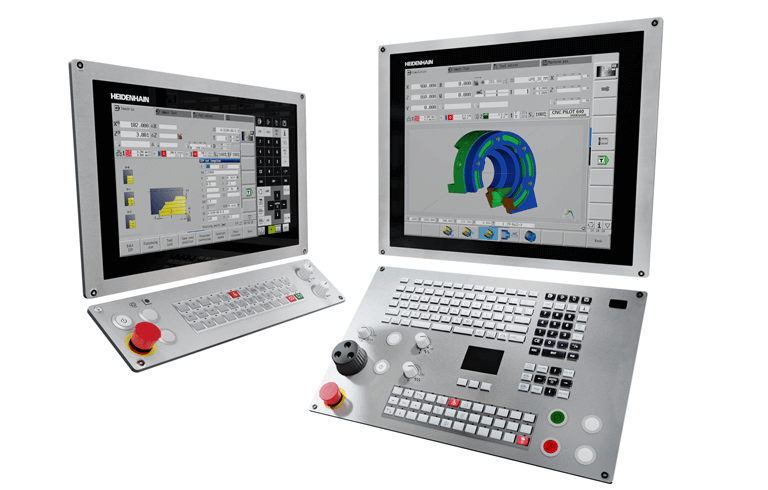

Users of HEIDENHAIN lathe controls value their ease of operation and programming, which is supported by numerous intelligent functions. Working with a CNC PILOT 640 or MANUALplus 620 requires very little training time. Meanwhile, touch probes, camera systems, and electronic handwheels provide practical support at the machine, reducing setup time and increasing process reliability. Programming stations are also available for creating, testing, and optimizing NC programs away from the shop.

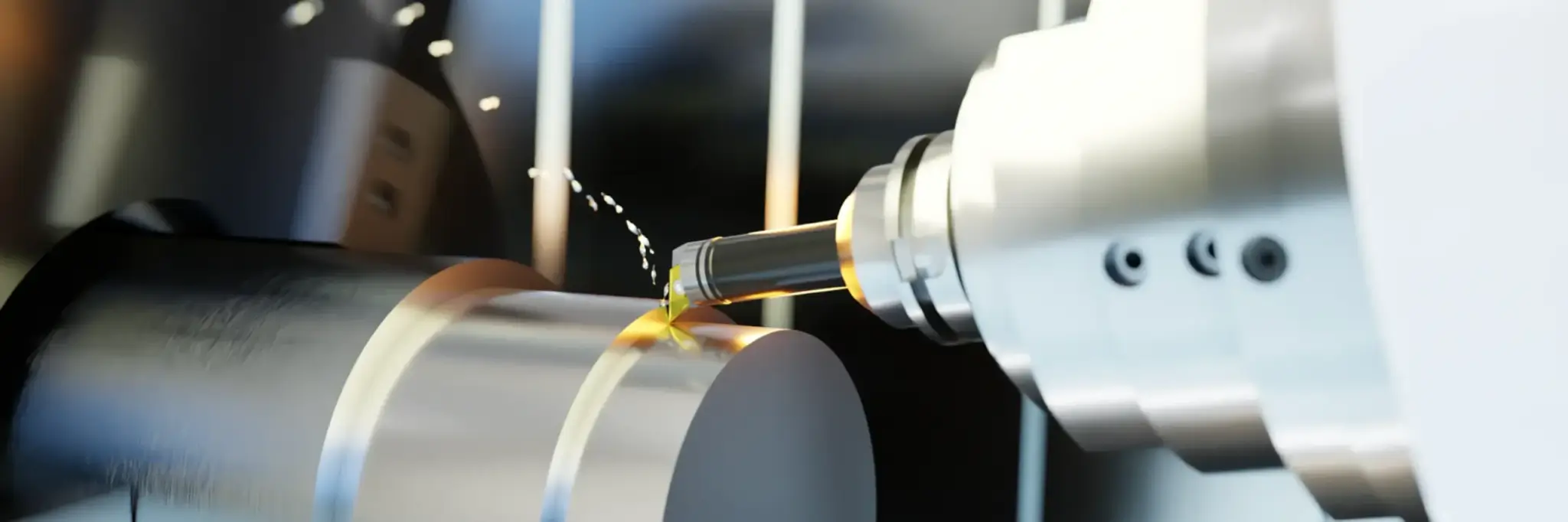

Tool and workpiece measurement

Tool and workpiece measurement Fine manual axis control

Fine manual axis control A copy of the control in your office

A copy of the control in your office

Manually operated machines made easy

Manually operated machines made easy Digital motor control

Digital motor control