Grinding machines and other machine tools

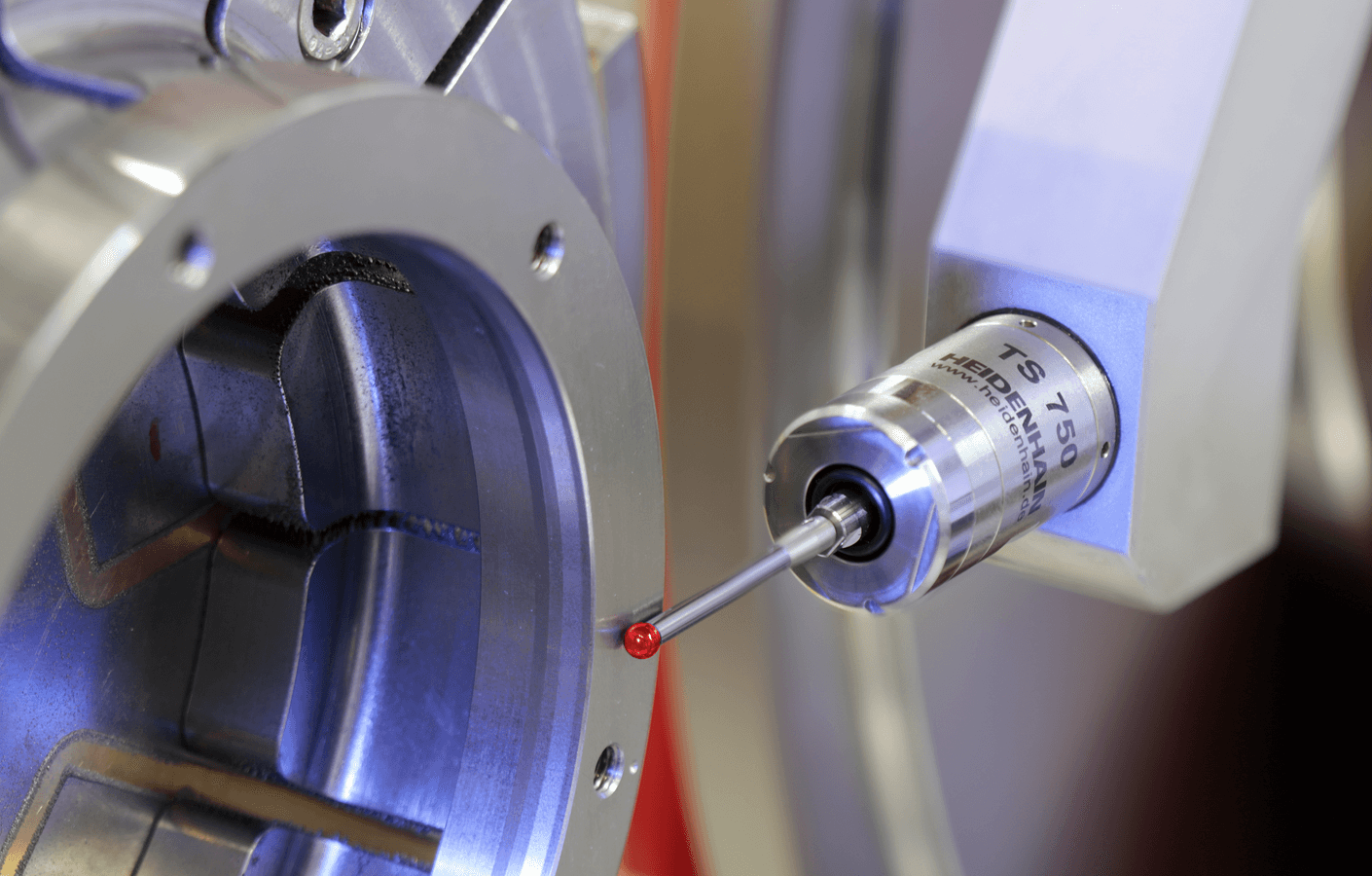

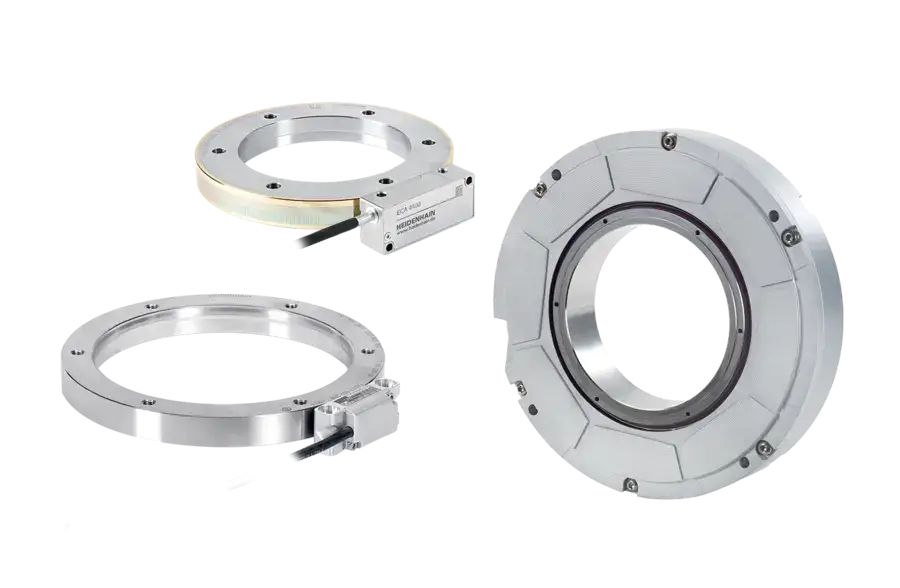

HEIDENHAIN offers a variety of products for grinding machines. With their low probing forces and long service lives, HEIDENHAIN touch probes are ideal for the unique requirements of grinding. In many grinding applications, angle encoders and linear encoders ensure high-accuracy positioning of the workpiece and grinding wheel while enabling dynamic motion control.

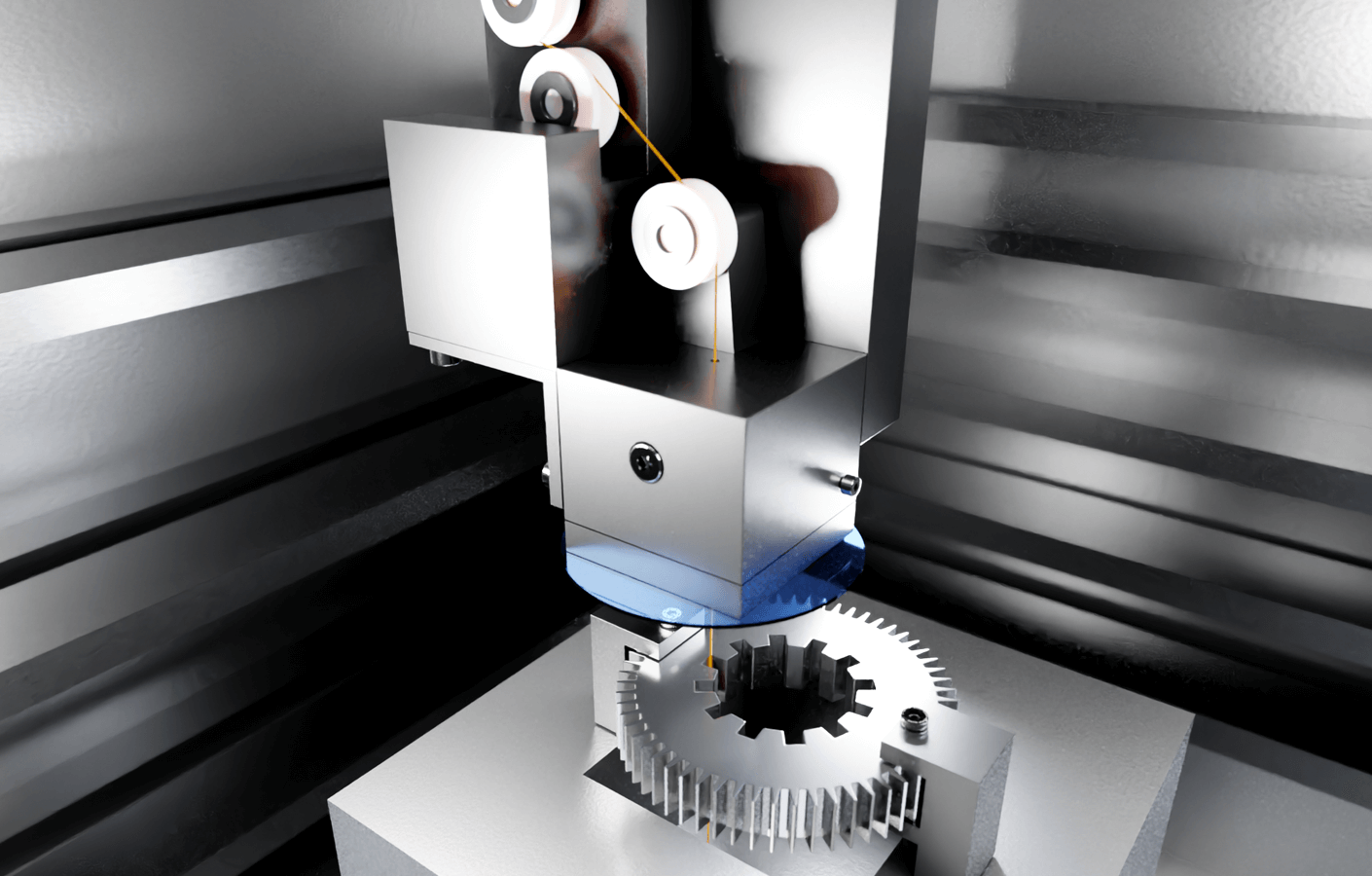

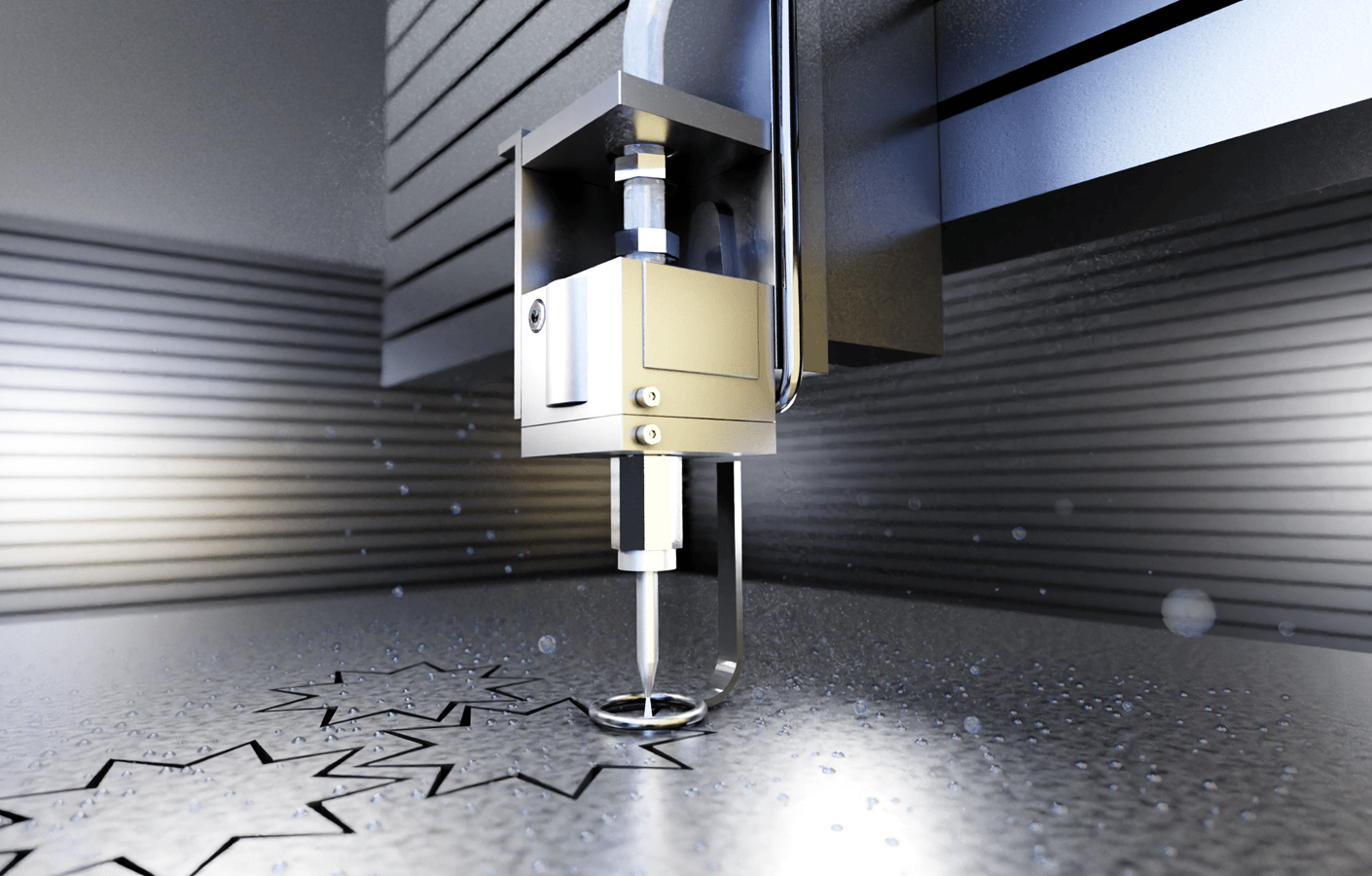

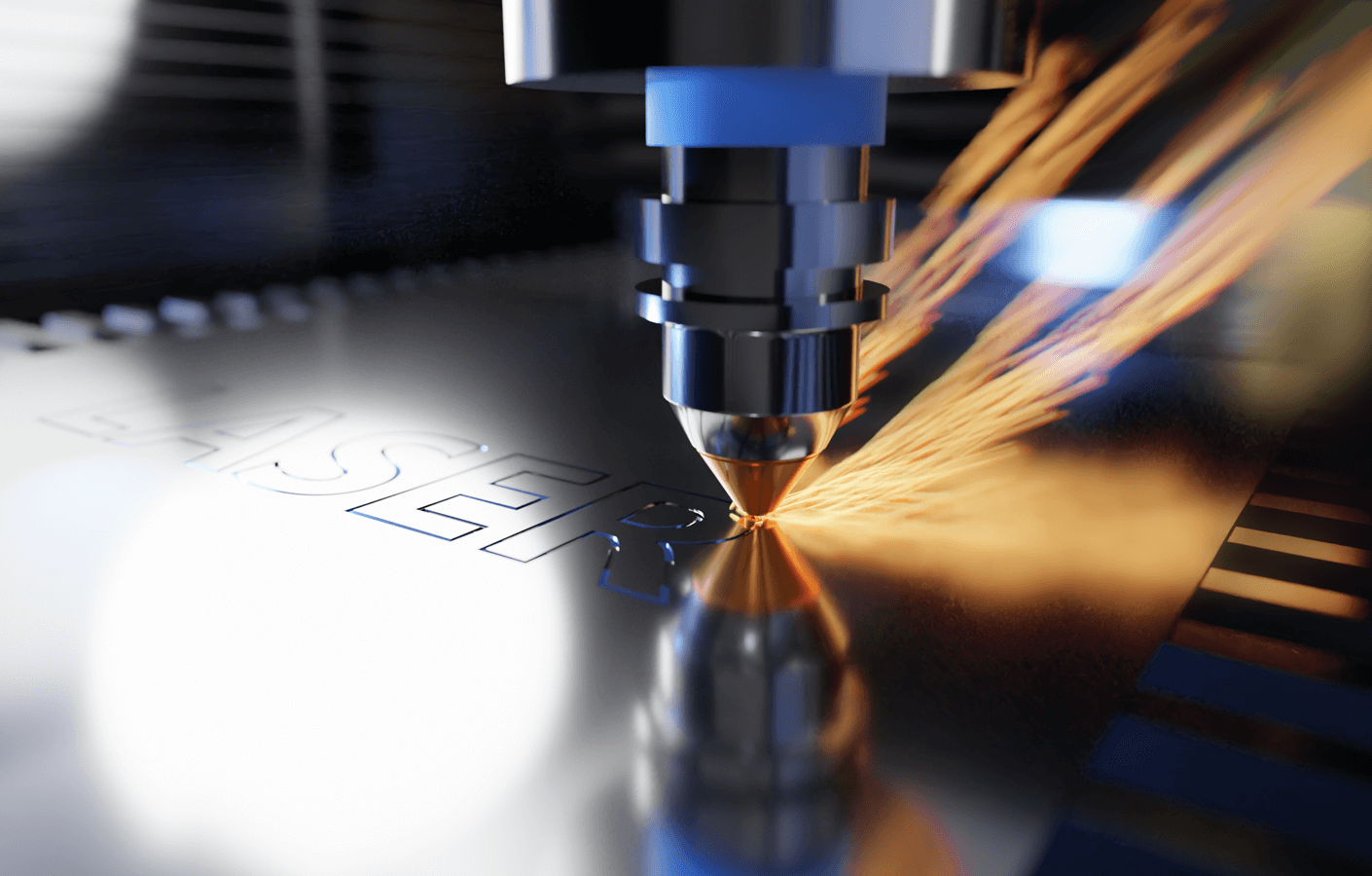

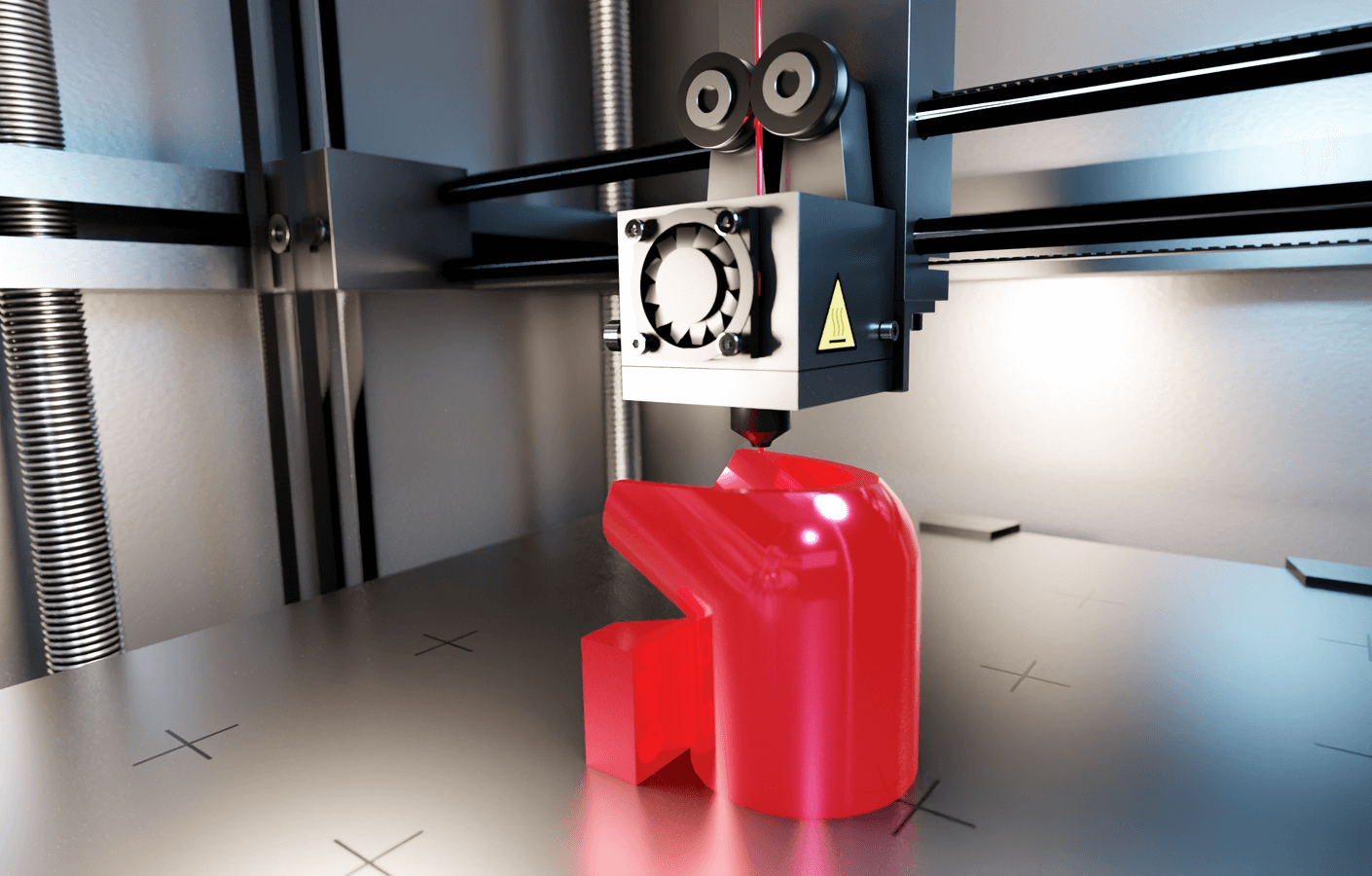

In applications such as EDM, laser cutting, water-jet cutting, sheet metal bending, and 3D printing, linear encoders ensure accurate, dynamic, and reliable position measurement. This is especially important for the particularly demanding conditions of some of these machining operations.