Elevator technology

Elevators must be safe and comfortable. Encoders from HEIDENHAIN, AMO, and RENCO make this possible. When installed on the main motor, brakes, shaft copying system, and doors, these encoders help the elevator car start gently, stop at just the right height, rapidly open and close its doors, and smoothly speed off again, all while meeting the highest safety standards. They also deliver the data needed for operational monitoring.

Motor control

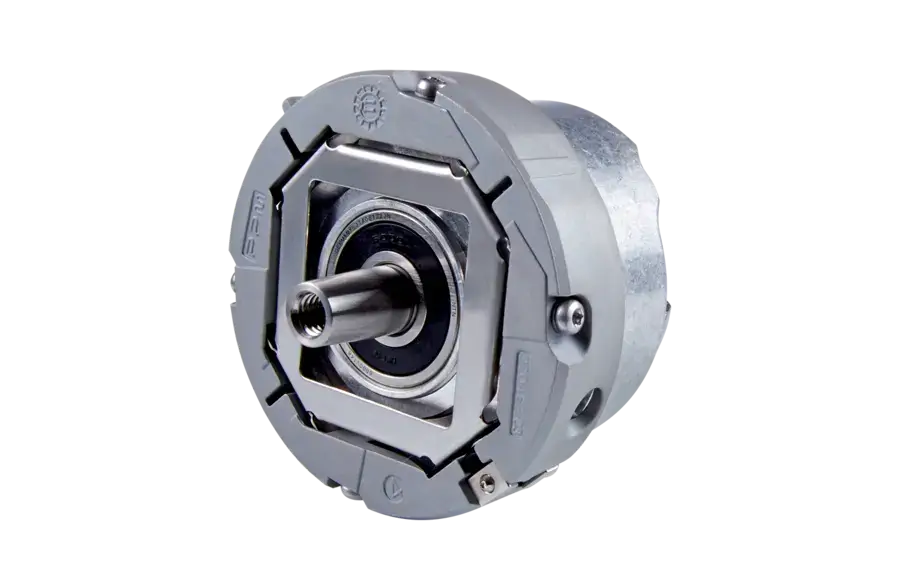

Ruggedness, reliability, and high resolution are key qualities of HEIDENHAIN rotary encoders. These characteristics make them proven and dependable motor control solutions on conventional traction elevators, able to meet the following elevator manufacturer requirements:

- High speed

- High travel height

- Compact design

- Low operating cost

- Numerous electrical interfaces to downstream electronics

Our products for motor control in conventional traction elevators

Motor control of the future

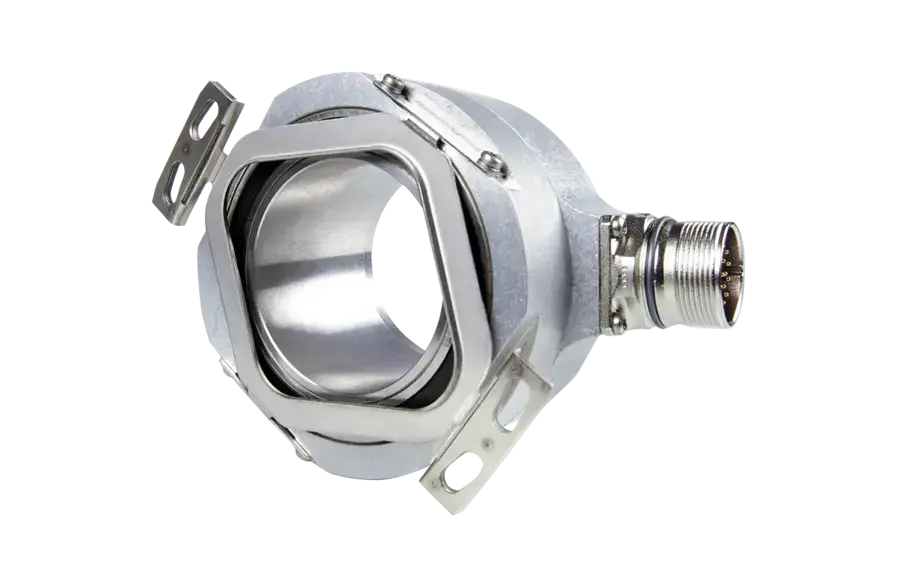

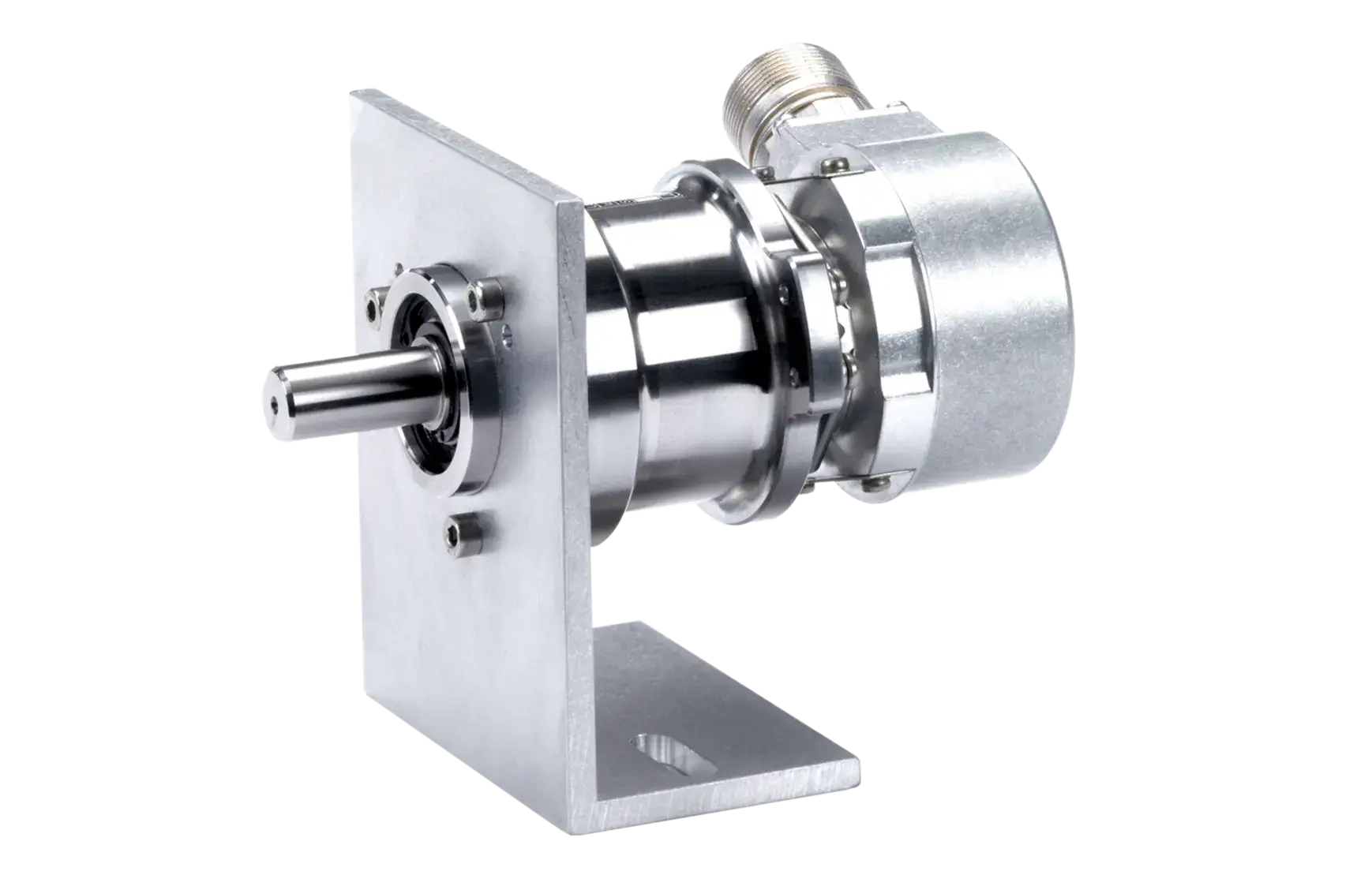

KCI 419 Dplus rotary encoder for elevators: two-dimensional is outdated

The KCI 419 Dplus inductive elevator rotary encoder delivers far more than position feedback for motor control on traction elevators. It can also detect the brake stroke without additional microswitches and measure the brake temperature. The KCI 419 Dplus is therefore optimally suited for brake monitoring. Via the EnDat interface, it even provides diagnostic data to downstream electronics, which can then derive the brake status (released or engaged) and the level of brake wear.

Traction elevators of the future won’t need microswitches for brake release monitoring. In the more distant future, elevators will be cableless, enabling horizontal travel.

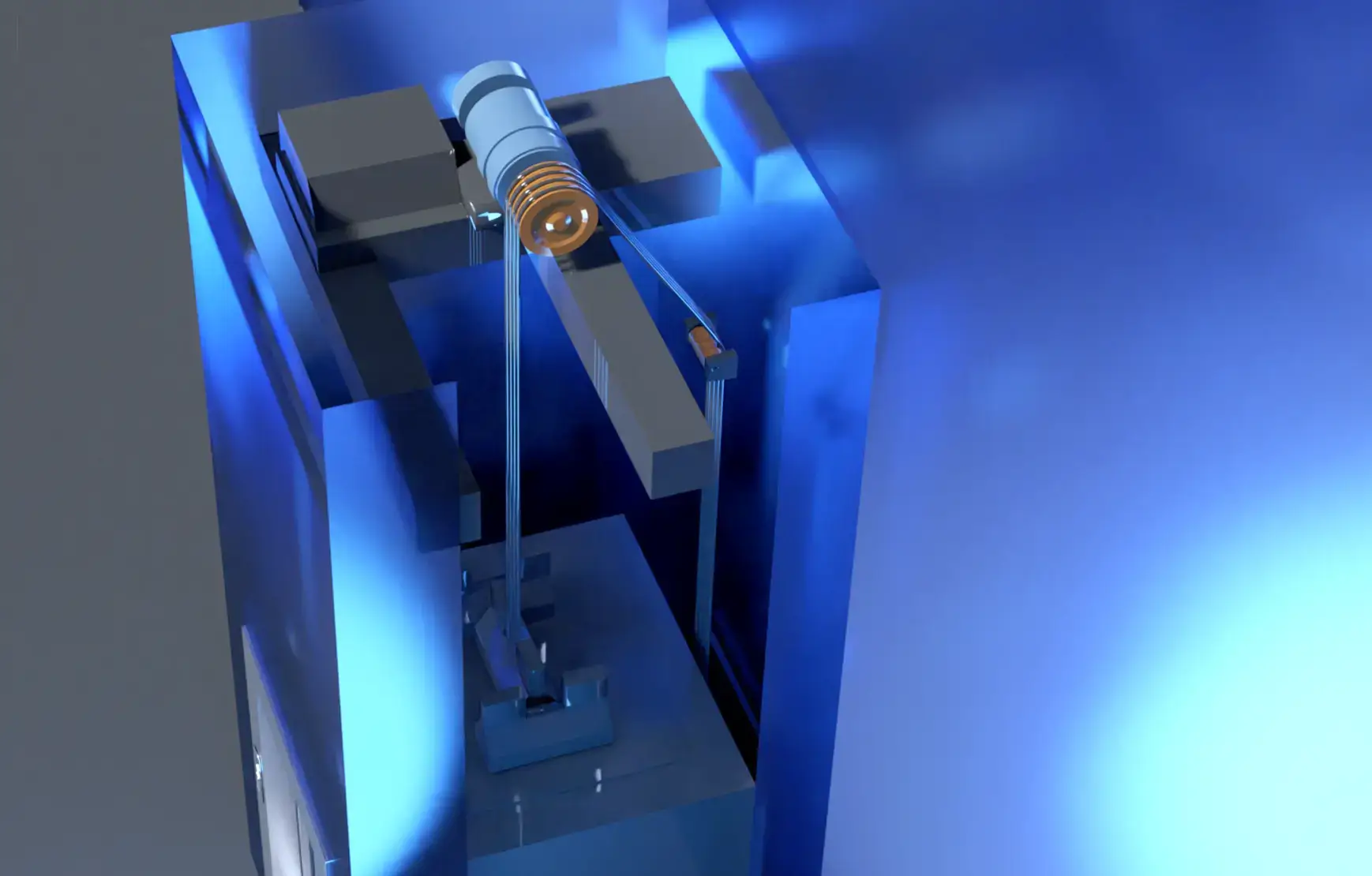

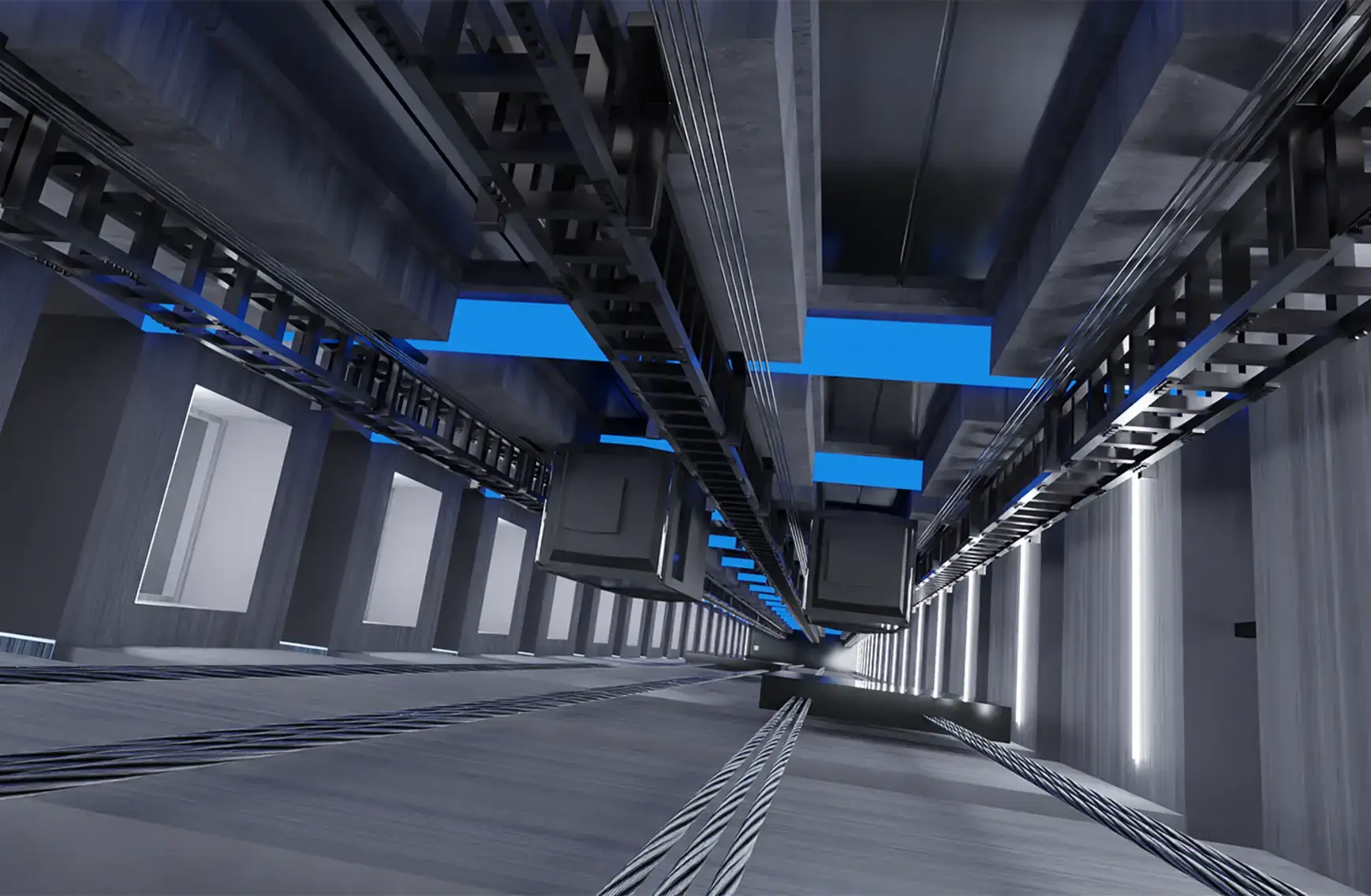

LINA 200: the absolute linear encoder for cableless elevators of the future

Imagine a cableless elevator cabin that moves both vertically and horizontally. HEIDENHAIN delivers the encoder technology needed to make this vision a reality: the LINA 200 absolute inductive linear encoder has a measuring standard consisting of two tracks with different signal periods from which the absolute position value can be derived.

AMO WMKA: change direction between vertical and horizontal travel

In the cableless elevators of the future, the change in direction from vertical to horizontal will be performed within the elevator shaft at rotational joints driven by high-powered torque motors. The position data required for controlling these motors will be provided by angle encoders such as the AMO WMK. Alternatively, exposed linear encoders such as the HEIDENHAIN LIC series can be used as well.

Shaft copying

For properly timed, jerkless braking, and exact positioning of the elevator car, its position in the shaft must be precisely measured and transmitted to the control. Absolute rotary encoders from HEIDENHAIN enable digital shaft copying with clear advantages:

- The absolute position of the car is continuously available, even after a power outage.

- Thanks to this continuously available actual position information, the car can be moved straight to its destination.

Door motors

Shorter elevator stopping times and higher transport volume can be attained if doors are opened and closed with speed and precision. The key to this is accurate and dynamic position measurement. HEIDENHAIN rotary encoders for door motors deliver the necessary rotational speed and position feedback in a highly compact design, with all models featuring an outside diameter smaller than 40 mm.