Encoders for dynamic automation

Slip rings for dynamic automation

Today, automation is all around us—and the demands are greater than ever. Engineers must answer the call for dynamic automation solutions that are safe and efficient. Our encoders are well suited to support these needs—including fast-cycle-time applications that require external sensor information (such as temperature).

Encoders for heavy-duty automation

Today’s heavy-duty automation applications demand encoders are smarter, more useful and more compact than ever before. Most importantly, they must be exceedingly durable and reliable. Our encoder solutions collect high-resolution speed or position data at the moment of motion, to achieve the most efficient motion control—no matter how harsh the working environment. They also offer in-demand functionalities including condition monitoring, overspeed relays and efficient fieldbus connectivity to support very short cycle times.

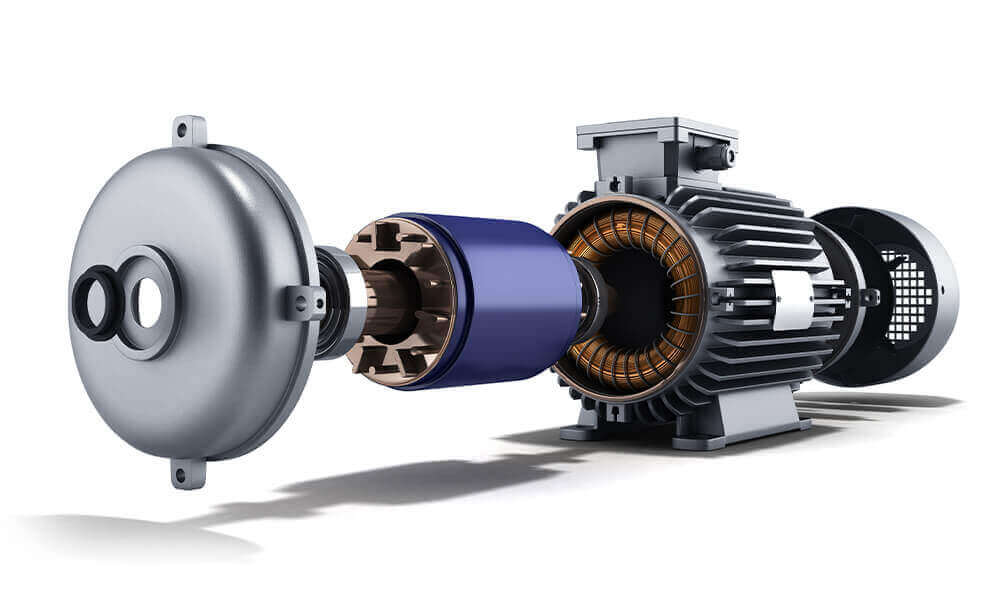

Encoders for demanding servo drive applications

Demands on servo drives are higher than ever: greater positioning accuracy, speed stability, bandwidth and safety. Answer the call with measuring components that provide the most reliable positioning feedback. We offer the widest range of rotary solutions to meet any servo motor needs—from extreme precision to heavy-duty durability.

Encoders for demanding drive system applications

Today’s automation and drive system applications demand heavy-duty encoders are smarter, more useful and more compact than ever before. Most importantly, they must be exceedingly reliable. Our encoder solutions for motion control systems collect high-resolution speed or position data at the moment of motion, to achieve the most efficient motion control—no matter how harsh the working environment. They also offer in-demand functionalities including condition monitoring, overspeed relays and efficient fieldbus connectivity to support very short cycle times.

Encoders for modern stepper motor needs

Our encoders act as the ideal feedback system for closed-loop stepper motors—thanks to a high resolution of up to 10,000 signals per revolution (40,000 measuring steps after four-fold evaluation) and a wide working temperature range of –30 degrees to +115 degrees Celsius. They also provide three commutation signals—U, V, and W—in order to power the rotor windings of BLDC motors (brushless DC motors) with up to four pole pairs.

Encoders for the most demanding motor drive applications

No matter the motor drive application, we have an encoder brand and product to meet the need. From compact pulse-generating solutions to high-accuracy precision systems, our solutions cover a wide range of needs related to speed, accuracy, durability, functional safety and reliability.

Encoders for industrial robotics

Industrial robotic applications call for heavy lifting—literally. But finding an encoder solution that enables powerful automation and superior accuracy can be a challenge. In fact, depending on their design, maximum range, and maximum load capacity, articulated robots typically achieve an absolute position accuracy of ±1 mm—insufficient for industrial applications that require extreme precision (such as aerospace). Fortunately, new encoders are enabling game-changing industrial robotics.

Encoders for pick-and-place automation

Pick-and-place automation solutions are becoming more and more commonplace in manufacturing and warehouse environments, with myriad demands and capabilities. Precision and repeatability are crucial, and dependent on superior encoder technology. Our encoders are well suited to keep up with the dynamic communication required for pick-and-place applications.

Encoders for AGVs

Increasingly prevalent in manufacturing and warehouse environments, AGVs and other mobile automation allows for increased efficiency—but the stakes are high. New encoder technologies enable safer, more accurate and repeatable motion and speed control. Furthermore, slim and lightweight design allows motor designers more flexibility, especially in these applications where space and weight is critical.

Encoders for robotics

Robotics are in high demand—and the demands on the technology are even higher. Repeatability, accuracy and safety are crucial. New encoder technology is enabling more possibility than ever before—from built-in functional safety to industrial durability. They also provide three commutation signals—U, V, and W—in order to power the rotor windings of BLDC motors (brushless DC motors) with up to four pole pairs.

Reliable encoders for top drive applications

Mission-critical oil and gas machinery must stand tough—and stay safe—in the face extreme moisture, corrosive materials, heat and cold, shock, vibration and more. Our unparalleled encoder technology is up for the challenge, providing accurate measurement and speed control for motor feedback in top drive applications. You’ll find encoders to fit a variety of industry demands—including those certified for use in ATEX/IECEx zone 1/21—hazardous, potentially explosive atmospheres.

Reliable encoders for draw works

Mission-critical oil and gas machinery must stand tough—and stay safe—in the face extreme moisture, corrosive materials, heat and cold, shock, vibration and more. Our unparalleled encoder technology is up for the challenge—providing quality speed feedback and condition monitoring features for draw works applications. You’ll find encoders to fit a variety of industry demands—including those certified for use in ATEX/IECEx zone 1/21—hazardous, potentially explosive atmospheres.

Reliable encoders for mud pumps

Mission-critical oil and gas machinery must stand tough—and stay safe—in the face extreme moisture, corrosive materials, heat and cold, shock, vibration and more. Our unparalleled encoder technology—well protected, up to IP 66—is suited for the rigorous environment of mud pump applications. You’ll find encoders to fit a variety of industry demands—including those certified for use in ATEX/IECEx zone 1/21—hazardous, potentially explosive atmospheres.

Reliable encoders for oil and gas

Mission-critical oil and gas machinery must stand tough—and stay safe—in the face extreme moisture, corrosive materials, heat and cold, shock, vibration and more. Our unparalleled encoder technology is up for the challenge. You’ll find encoders to fit a variety of industry demands—including those certified for use in ATEX/IECEx zone 1/21—hazardous, potentially explosive atmospheres.

Encoders for medical scanning or radiation

Diagnosis—and treatment—of life-threatening medical conditions continues to improve, thanks in large part to ever-more precise technology. Better encoder technology plays a role, helping medical professionals with more accurate x-rays/imaging; meanwhile, more accurate encoders enable radiation treatments that target smaller areas to minimize damage to surrounding cells.

Encoders for blood pumps

Blood pumps in a multitude medical devices (such as hematology analyzers) rely small and lightweight, yet powerful, encoders. New technologies allow for slimmer encoder designs that deliver all the functionality and dependability necessary for this high-stakes application.

Encoders for lab automation

Achieving the high throughput and extraordinary accuracy necessary for lab automation—liquid handling, DNA sequencing and sample analysis to name a few—is extremely challenging. But new technologies (including ever-more accurate encoders) are changing the game.

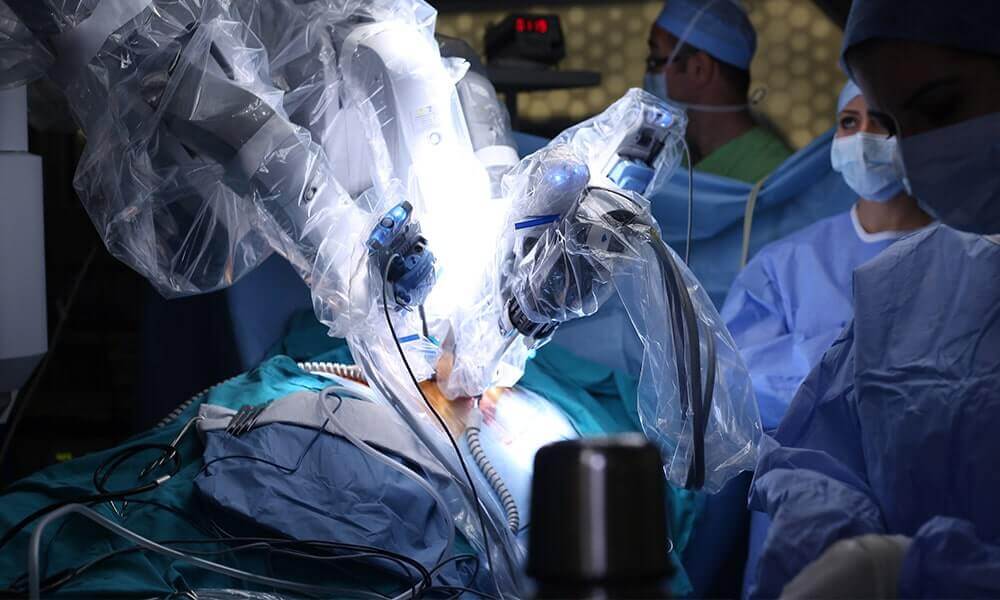

Encoders for medical

Medical technology is an extremely sensitive industry, in more ways than one. But from remote robotic surgery to medical device design, technologies are enabling miraculous outcomes. New encoder technology is a rarely recognized, but crucial, element in the accuracy and dependable control that enables these advances.

Superior encoders for printing

Printing techniques and capabilities are getting more and more advanced, thanks to unsurpassed motion and positioning control. Engineers striving to design competitive technologies must identify components that support extreme precision at super-rapid speeds. Our encoders are some of the most accurate and reliable encoders on the market and are a necessity for any high-resolution print application.

Superior encoders for printing

Printing techniques and capabilities are getting more and more advanced, thanks to unsurpassed motion and positioning control. Engineers striving to design competitive technologies must identify components that support extreme precision at super-rapid speeds.

Encoders for wind turbine generators

Wind power is the fastest-growing renewable energy source in the world. Specialty encoders for this industry provide increasingly accurate positional information to the main control system to optimize generator speed relative to wind speed and direction; dependable, high-quality components—built to withstand the elements—are of the utmost importance.

Encoders for wind turbine rotor blades

Encoders on the rotor blades of a wind turbine must withstand extreme conditions, while transmitting accurate power and control signals. A variety of durable, virtually maintenance-free encoders help enable more efficient, dependable alternative energy.

Encoders for wind turbines

Wind power is the fastest-growing renewable energy source in the world. Specialty encoders for this industry provide increasingly accurate positional information to the main control system to control blade pitch and optimize generator speed relative to wind speed and direction; dependable, high-quality components—built to withstand the elements—are of the utmost importance.

Your solutions:

For the most demanding automation applications, HEIDENHAIN delivers nanometer-level precision and unyielding reliability.

Variety, value and ease of use make Renco a smart choice for most general automation applications.

Built rugged and designed for harsh environments, Leine Linde encoders minimize downtime in mission-critical automation applications.

The world’s leading manufacturer of inductive linear and angular encoders for harsh and contaminated automation environments.

For the most demanding automation applications, HEIDENHAIN delivers nanometer-level precision and unyielding reliability.

Built rugged and designed for harsh environments, Leine Linde encoders minimize downtime in mission-critical automation applications.

The world’s leading manufacturer of inductive linear and angular encoders for harsh and contaminated automation environments.

For the most demanding automation applications, HEIDENHAIN delivers nanometer-level precision and unyielding reliability.

Built rugged and designed for harsh environments, Leine Linde encoders minimize downtime in mission-critical automation applications.

For the most demanding automation applications, HEIDENHAIN delivers nanometer-level precision and unyielding reliability.

Variety, value and ease of use make Renco a smart choice for most general automation applications.

Built rugged and designed for harsh environments, Leine Linde encoders minimize downtime in mission-critical automation applications.

For the most demanding automation applications, HEIDENHAIN delivers nanometer-level precision and unyielding reliability.

Variety, value and ease of use make Renco a smart choice for most general automation applications.

Built rugged and designed for harsh environments, Leine Linde encoders minimize downtime in mission-critical automation applications.

For the most demanding automation applications, HEIDENHAIN delivers nanometer-level precision and unyielding reliability.

The world’s leading manufacturer of inductive linear and angular encoders for harsh and contaminated automation environments.

Variety, value and ease of use make Renco a smart choice for most general automation applications.

Built rugged and designed for harsh environments, Leine Linde encoders minimize downtime in mission-critical automation applications.

For the most demanding automation applications, HEIDENHAIN delivers nanometer-level precision and unyielding reliability.

The world’s leading manufacturer of inductive linear and angular encoders for harsh and contaminated automation environments.

RSF Elektronik is recognized by medical equipment builders the world over as a leading producer of electronic linear and modular angle encoders.

For the most demanding automation applications, HEIDENHAIN delivers nanometer-level precision and unyielding reliability.

The world’s leading manufacturer of inductive linear and angular encoders for harsh and contaminated automation environments.

RSF Elektronik is recognized by medical equipment builders the world over as a leading producer of electronic linear and modular angle encoders.

With an innovative approach to integrated motion systems, ETEL can help pave the way for groundbreaking automation.

Variety, value and ease of use make Renco a smart choice for most general automation applications.

LTN takes a unique approach to delivering precision rotary encoders, placing an emphasis on sustainable applications and strong customer partnerships.

For the most demanding automation applications, HEIDENHAIN delivers nanometer-level precision and unyielding reliability.

The world’s leading manufacturer of inductive linear and angular encoders for harsh and contaminated automation environments.

Variety, value and ease of use make Renco a smart choice for most general automation applications.

RSF Elektronik is recognized by medical equipment builders the world over as a leading producer of electronic linear and modular angle encoders.

For the most demanding automation applications, HEIDENHAIN delivers nanometer-level precision and unyielding reliability.

The world’s leading manufacturer of inductive linear and angular encoders for harsh and contaminated automation environments.

RSF Elektronik is recognized by medical equipment builders the world over as a leading producer of electronic linear and modular angle encoders.