Steel Industry: Precision and power anywhere

Grease, dust, extreme temperatures and vibration are just a few of the environmental factors that come into play in steel production and refining. We’ve found innovative ways to build devices that maintain the power and precision we’re known for in such daunting scenarios.

Why choose HEIDENHAIN products in steel processing

Specialized precision systems

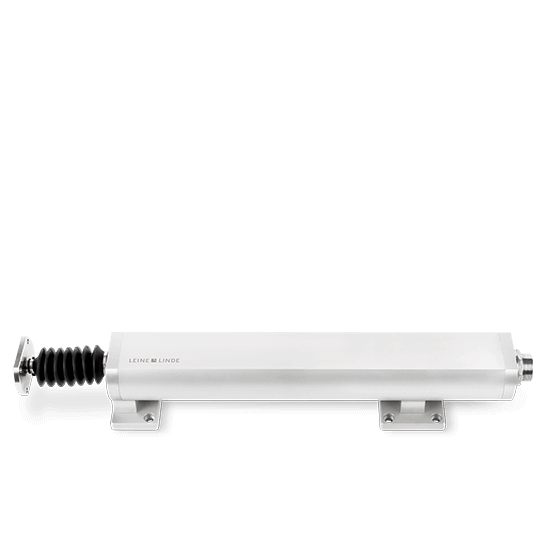

Any number of environmental factors in a steel mill can negatively impact high-horsepower motion control. Not just any feedback device can stand up to the potential contaminants, shock or temperatures. This is why we’ve developed bearingless, safe-motion and modular enclosed encoders, with some of the highest IP ratings and most protective bodies and connections available.

Torque when you need it

Rolling mills are no simple piece of equipment to manage. Controlling their speed and adjusting roll heights require just the right amount of torque at the right times. We offer an array of powerful motors, with extremely condensed force densities, that are an ideal fit when controlling heavy loads moving at different speeds.

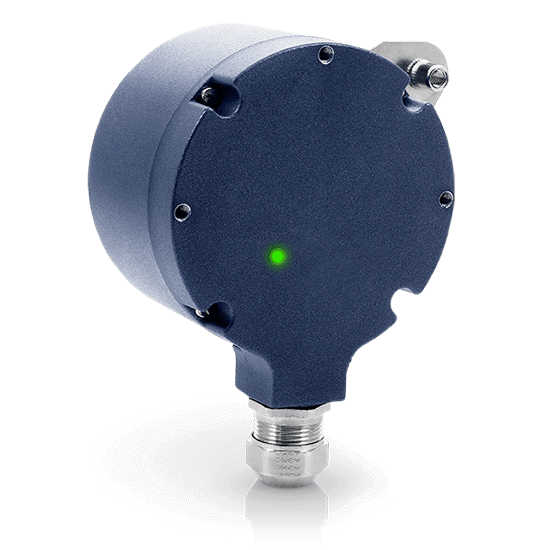

Predictable maintenance

Today’s encoders can do more than just control speed, they can observe environmental data, alerts and maintenance recommendations. These versatile encoders are especially valuable in such extreme environments, where dirt, vibration, heat, temperature fluctuations and mechanical forces wear on systems.