Digital manufacturing in action at Krones

Streamlining its manufacturing processes, world-leading manufacturer of technology for liquid Consumer Packaged Goods (CPGs), Krones Inc. continues to grow by taking advantage of new technologies and connecting systems to work better and faster. Using their mold-making 5-axis machining area equipped with HEIDENHAIN TNC controls as part of a worldwide pilot process for the past three years, Krones Inc. manager John Vincent, based in Franklin, WI discusses how they are now working with these systems in a global manner.

“Since we are a subsidiary of a worldwide company based in Germany, it is common for us to have to manufacture redundant parts in our plants all over the world,” explained John Vincent, Head of Manufacturing Technologies for Krones Inc., the North American headquarters based in Franklin, WI. “And we have found a way to streamline this to be more efficient, thus providing optimized parts to our end users faster and better than ever before.”

Vincent explains how his approximately 8,000-square-foot mold-making area at the Krones Inc. 300,000-square-foot facility is currently equipped with four HEIDENHAIN iTNC 530-controlled machines that make the molds doing the cavity work.

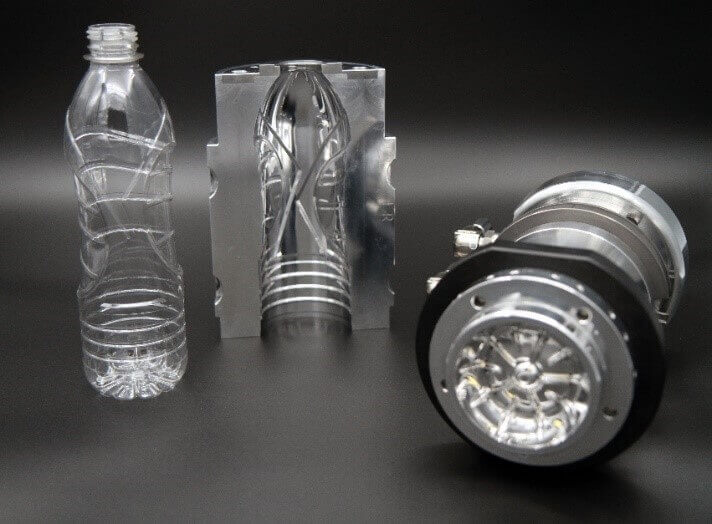

This area also includes two smaller auxiliary machines, their own Quality Control department with CMM for inspection work, and an assembly area. Here in Wisconsin, Krones Inc.’s current primary role is to manufacture and supply parts for its large blow molding, filling, labeling, and packing technology installed throughout North America, Central America, and the Caribbean. Common jobs in the mold-making department include manufacturing molds for stretch blow molding machines for PET plastic bottles for water, soda, and other liquid products. Typical part lot size is 40 pieces (20 mold sets) in an average cycle time of four hours.

“We are making very tight tolerance, similar mold parts at all these locations, all requiring high accuracy, as well as highly polished surface finishes down to RA right out of the 5-axis machine,” said Vincent, “and by working together, we have been able to incorporate each other’s best practices and provide an excellent end-product.”

As part of the pilot program that started three years ago, Krones Inc. has undergone steps to connect to its Krones Group affiliates in China and Germany. Utilizing a FORCAM digital software system (similar to HEIDENHAIN’s newly introduced StateMonitor), Krones Inc. staff has programmed the HEIDENHAIN controls in each of these three locations to connect and interact with each other when called upon to do so.

“This set up allows us to measure the actual usage of any machine at any time, and when they stop, there are protocols provided for next steps including the ability to enter costs codes to track why it stopped, so there’s connectivity between all the machines,” said Vincent who explained there are actually about 65 CNC-controlled machines throughout his entire Wisconsin location.

“I think it is important to note that we have done tests in the mold-making department where we’ve run programs from both Krones in Germany as well as Krones in China that were selected within our software systems and were able to run them here in Wisconsin just fine! This is particularly helpful for customer development work.

“For example, we recently had an order for a new bottle on a Monday, so that day we designed a mold for it. Then I sent an email to a Chinese colleague asking for them to design a program for it (their daytime is our night),” explained Vincent, who added that their Chinese mold-making department has six HEIDENHAIN iTNC 530s in use. “So, when we came into work on Tuesday morning, we loaded the program from our Chinese colleague into our iTNC 530 and started running it, and had the part done that same day for customer review. And this is a part that probably has a cycle time of five hours, so it isn’t something on which we can minimize run time. This process is one that our customers continually request be done quicker, and we are happy to now be able to do it.”

TNC Role in Krones Inc. Connected Machining

Krones Inc. has been utilizing the HEIDENHAIN TNCs in their mold-making departments for some time, with change-outs to updated machines approximately every five years. “I’m a huge fan of the HEIDENHAIN controls,” explained Vincent. “Particularly in the mold-making industry, these controls definitely have a leg up on the competition as far as being able to achieve excellent and accurate surface quality at high speeds.

“There are many useful features that I particularly like such as the manual probing routine on the machine via soft keys right on the control. You don’t find that on other controls and it’s a well-used feature for in-process inspection.”

As new employees, Krones Inc. machinists receive training on the controls, though Vincent adds that once his employees learn the HEIDENHAIN control they usually don’t want to go back to another. The TNCs are conversational, and while Vincent admits that many new employees are hesitant to try something new, “after some training, they say they would never run anything but.”

Vincent adds that he and his staff find many TNC control features easy to use, making special mention of the ability to do things on the fly and/or add checking programs by the operators, as well as the way the tool table systems work. “We use a tool data management software that incorporates well with the TNC. With this, we assign a number to every tool assembly in our plant, and with the TNC, we can call out that number and it doesn’t matter where it is in our machine tool magazine, the operator can pull it. It’s easy since you don’t always have to have tool number one in pocket number one. This is a real benefit to us and not something I see with other controls.”

Here, Krones Inc. staff is utilizing the extended tool management feature where they can load and unload from the list of tools by simply dragging and dropping with the computer mouse. A tool usage list provides more details, and an import function allows for reading and exporting CSV files.

Another important TNC control feature used by Krones Inc. is the HEIDENHAIN DNC option, providing the ability to communicate with external Windows applications. In use as well is the Remote Desktop Manager, which provides the user the opportunity to operate one or more Windows PCs directly from the TNC. “We use the TNC Remote commonly to load programs into the machine’s control from various locations,” explained Vincent.

Aside, Vincent also describes another unique manufacturing system at Krones Inc. that utilizes an iTNC 530 in a different area in the plant. This one is incorporated on a machining center producing pallets for labeling machines that applies labels to bottles, such as beer bottles or BBQ sauce bottles. “In this system, we actually configured a waterjet into a 5-axis machining center. We were able to use the features in the TNC control to create multiple setup kinematics to handle using the normal milling spindle as well as the separate auxiliary waterjet feature. We are using a GF Mikron machine with a pallet changer (up to 21 parts), and all the data is set up so that an operator can pull in the appropriate program so that the machine moves successfully between milling and water jetting as needed. It’s working out great!

“This connected machining has really been going strong on a daily basis here at Krones over the last year, and we are now working to expand it to other departments,” added Vincent.

Importance of Training and Support

To keep this large organization at the top of its game, Krones’ culture includes daily employee support and training as needed.

“As we look to the future of manufacturing and global connectivity, we know that it is important to know what today’s advanced capabilities offer,” said Vincent. “We understand that it’s beneficial to have skilled staff that can and want to interact with our machines to customize and optimize the end products. We applaud these efforts, and work to empower our people to do so.”

Vincent explained that Continuous Improvement programs where employees meet in groups weekly are part of this process. He also adds that both in-house and external machine training is provided to Krones employees. Last year, for example, eight Krones Inc. employees were sent to HEIDENHAIN’s North American headquarters in Schaumburg, IL, to participate in a four-day TNC control training week where they were able to enhance their skills and learn tips to do even more. Since HEIDENHAIN keeps these classes small and customized, Krones was able to have a dedicated trainer to themselves the entire time.

“Training at HEIDENHAIN encourages full use of this conversational control in various ways and enables greater creativity for the operator to fully use its features,” explained Vincent. “I’d say 95% of Krones programs come from a CAD system, but when using a HEIDENHAIN control, our operators can easily fine-tune them, right at the control as needed. This allows improvements otherwise not realized and allows our operators to take ownership of their work.”

“After the training at HEIDENHAIN, I spoke to all eight of our employees that attended, and every one of them expressed that this was a positive experience. Some even requested to go back another time for more advanced classes since HEIDENHAIN just introduced a much larger TNC training schedule in 2019.”