March 28, 2016

The diversity of tactile measurements

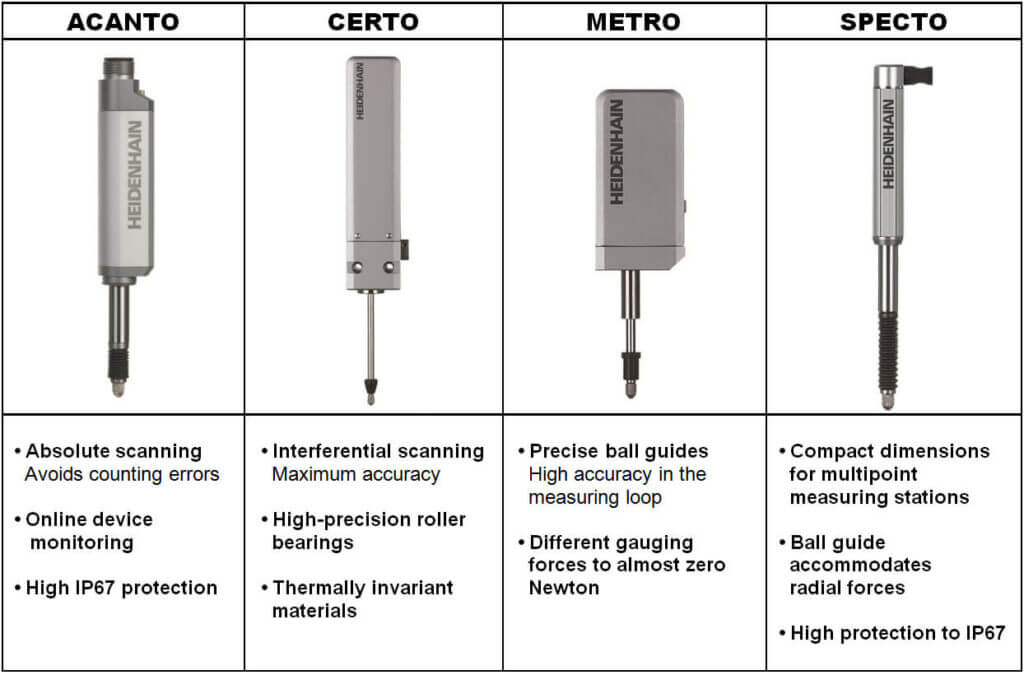

The four HEIDENHAIN length gauge product ranges: From online device monitoring and 0.1 µm accuracy to almost zero Newton gauging force

The number of metrology applications is almost infinite; automated testing, multipoint measuring stations and individual test stations are just a few of the variants, and each application demands specific properties of the encoders and evaluation electronics used. HEIDENHAIN provides a wide spectrum of solutions for such purposes which, thanks to photoelectric scanning, benefit from high accuracy across the complete measuring range.

The number of metrology applications is almost infinite; automated testing, multipoint measuring stations and individual test stations are just a few of the variants, and each application demands specific properties of the encoders and evaluation electronics used. HEIDENHAIN provides a wide spectrum of solutions for such purposes which, thanks to photoelectric scanning, benefit from high accuracy across the complete measuring range.

The diversity of uses for HEIDENHAIN length gauges is hardly less than the number of applications. For measuring rooms, the monitoring of measuring equipment or for manually operated measuring stations, the CERTO and METRO series are ideal, with accuracy of better than 1 µm. ACANTO and SPECTO length gauges, on the other hand, are suitable for automated test equipment and multipoint measuring stations because of their specific construction designs.

High accuracy over the complete measuring range means that several different components of various sizes can be measured with identical accuracy levels by all length gauge models. The result is that supplementary devices are not needed. All variants also feature special characteristics targeted at the wide diversity of applications. Together with suitable evaluation electronics, HEIDENHAIN solutions meet the highly specific demands of metrological tasks.

HEIDENHAIN ACANTO: Absolute length gauge with online device monitoring

In dynamic measuring tasks such as on test stands, counting errors can occur in the subsequent electronics when using incremental encoders. These are often caused by excessive speeds or vibrations. The absolute length gauges from the HEIDENHAIN ACANTO series avoid such counting errors by continuously determining the absolute position value for each request without needing a reference run, thus immediately providing a measured value. Measuring errors caused by excessive plunger speeds (e.g. from bounce) belong to the past.

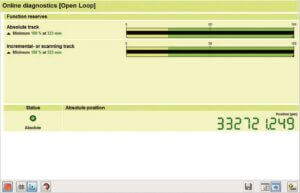

Online device monitoring for all machining steps and quality inspection steps providing information for quality assurance and machine maintenance

HEIDENHAIN ACANTO length gauges also supply analyzable data about the measurements, providing information about the specific rating with each machining step or quality testing step. This is made possible with the bidirectional EnDat 2.2 interface, which in addition to the position value provides further information about the length gauge:

- Valuation numbers supply data about the current state of the encoder. Continuous monitoring of the functional quality of scanning is therefore possible.

- Warnings and alarms allow conclusions to be drawn about components affected by failure, e.g. the light unit.

- Upon switch-on, the electronic ID plate immediately displays all technical parameters for the encoder. This avoids erroneous configuring of the evaluation electronics.

An important aspect of the Industry 4.0 topic is supporting people via technology, for example with self-configuration and self-diagnosis. The subsequent electronics can independently configure the signal period or measuring step with the transmitted information. Also, the EnDat 2.2 interface enables information to be written back to the length gauge. Two different corporate divisions directly benefit from this added value:

- Quality Assurance can determine the quality of measurements with the diagnostics information.

- Machine maintenance can avoid unnecessary idle times during production via advance inspections thanks to the valuation numbers.

The valuation numbers are dynamically generated in a similar way to the maintenance intervals for modern automobiles according to their driving conditions, with the encoder detecting whether a light source is aging, for example, or the scanning equipment is contaminated.

The measuring range of ACANTO length gauges is 12 mm or 30 mm according to specific version, with IP67 protection. The compact station width of 15 mm means they are also especially suitable for multipoint measuring stations.

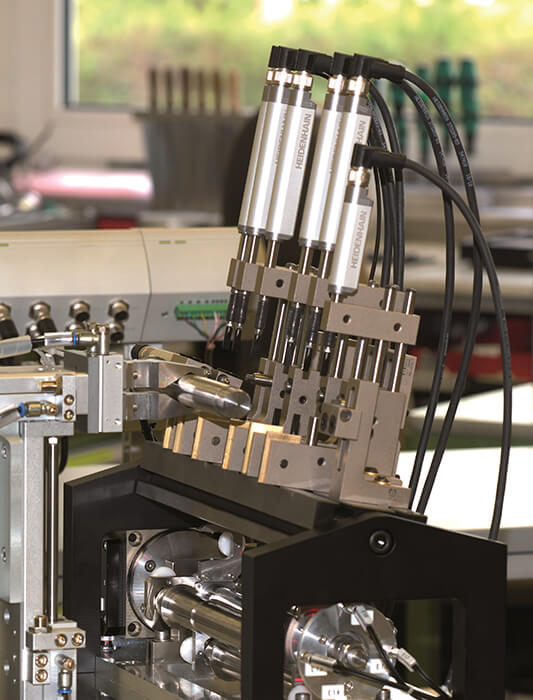

Solutions for HEIDENHAIN multipoint measuring stations: The modular MSE 1000 subsequent electronics for up to 250 measuring channels and an ACANTO length gauge with a station width of just 15 mm

Multipoint measuring equipment is gaining in popularity

Multipoint measuring stations are becoming ever more important in the field of industrial measuring technology. Electronics control the simultaneous measurement of several measured values on a test component in such applications, and often as part of a predetermined testing procedure with complex measuring tasks. The SPECTO series features a station width of just 13 mm for such applications, enabling several length gauges to be positioned in tight spaces. To keep space requirements in the system low, cables can be either axially or radially connected.

HEIDENHAIN SPECTO length gauges are also ideal for in-process measurements thanks to protection classes to IP67. Accuracy of ±1 µm is ensured over measuring strokes of 12 mm or 30 mm. The short-range accuracy (measurement error in a measuring range of 200 µm) is typically less than 0.3 µm, and repeatability has the same low value. These values are possible among other factors due to the highly precise ball guide, designed for a life of more than 60 million measuring cycles.

To ensure that data from multipoint measuring stations is reliably and quickly evaluated, HEIDENHAIN offers the MSE 1000 modular subsequent electronics, enabling the simultaneous measurement of up to 250 measurement channels over a wide variety of interfaces. When designing the MSE 1000, HEIDENHAIN placed an emphasis on simplicity for installation of the modules and connection to the encoder. Modules can be mounted to DIN rails to achieve tidy and compact measuring stations. The selected system configuration of the modules is detected automatically and unnoticed by the user, who only needs to define and set the specific channels.

The MSE 1000 also of course allows EnDat encoders to be connected in their entire functionality, enabling all the benefits provided by the ACANTO length gauges to be used for example. Valuation numbers, warnings, alarms and the ID plate can be displayed and queried via the unit. In addition to support for the EnDat HEIDENHAIN protocol for absolute encoders, all common incremental encoders, further connection options for analog sensors and LVDT and HBT displacement sensors from well-known producers are also supported. Modules with switching inputs and outputs enable interaction with other actuators in the encoder. A Compressed air switching module for direct control of e.g. pneumatically actuated length gauges is also available. Data transmission is via standard Ethernet.

The scope of supply of the MSE 1000 includes, in addition to a system configuration program, a DLL library that allows users to develop their own testing programs. With testing processes requiring further actions (depending on the measuring results), complex sequences can thus be stored.

Delicate workpieces measured tactilely and with high precision: The METRO range, with gauging forces from almost zero Newton

The ND 2100G GAGE-CHEK evaluation electronics are ideal for up to eight measurement channels, displaying the values of the single channels or directly evaluating these. The ND 2100G GAGE-CHEK can also carry out complex calculations via equations and comparisons, with the software and hardware enabling the saving of processes and responses and the controlling of switching inputs and outputs. In this way, PLC functionality can be integrated into the evaluation electronics.

HEIDENHAIN METRO and HEIDENHAIN CERTO: Measuring below 1 µm

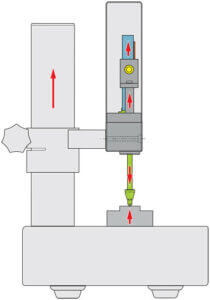

With an accuracy of ±0.1 µm and repeatability of 0.03 µm, the HEIDENHAIN CERTO length gauge gives you the most exact tactile measurement over a range of up to 60 mm that the market has to offer. HEIDENHEIN measures repeatability with five measurements across the complete measuring range near to the lower plunger stop. Repeatability specifies the difference between the initial measurement and the settled condition of the encoder after five measurements. The advantages of photoelectric sampling are exploited to the full, with the finest lines being sampled without contact and therefore without wear, thus enabling such outstanding technical parameters. The calibration chart also indicates a value for linear error compensation. In combination with an ND 287 evaluation unit, the achievable accuracy improves to ±0.03 µm.

Using the recommended CS 200 gauge stand even results in a thermally invariable measuring loop. Since the gauge stand and the HEIDENHAIN CERTO mechanism both consist of Invar (expansion 1 ppm/K) and the scale with 2 µm signal period is manufactured from ZERODUR (expansion 0.1 ppm/K), small variations in temperature, which generally cannot be avoided, do not affect the accuracy. Length gauge accuracy is specified in the range of 19 °C to 21 °C for this reason. For high-accuracy measurements, such as stations where the finished dimensions are checked, the optional analog module of the ND 287 can be used to compensate for deviations in the temperature of the workpiece or the entire system. The electrical motor of the length gauge offers three gauging forces and a constant probing force over the entire measuring range.

A further series in the accuracy grade below 1 µm is the METRO product range, and just like CERTO length gauges, these feature a precision graduation with a 2 µm signal period. This ensures system accuracy of ±0.2 µm over the entire measuring range of 12 mm or 25 mm. The interplay of ball bearing guides and high-precision photoelectric scanning achieves repeatability below 0.03 µm, and short-range accuracy with a measuring range of 12 mm is typically less than 0.03 µm.

Thermally induced length change. Expansion of the measuring loop components as a result of heat.

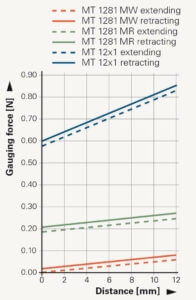

Tactile length gauge with a measuring force of almost zero Newton

Continued progress in the field of materials technology is leading to increased use of flexible materials such as elastomers in industry. The desire to produce ever more compactly also presents new challenges for the measuring of delicate workpieces. The undesired deformation of elastic parts caused by the encoder may distort measurement results, and workpieces made of highly sensitive materials can also damage or destroy the encoder.

Continued progress in the field of materials technology is leading to increased use of flexible materials such as elastomers in industry. The desire to produce ever more compactly also presents new challenges for the measuring of delicate workpieces. The undesired deformation of elastic parts caused by the encoder may distort measurement results, and workpieces made of highly sensitive materials can also damage or destroy the encoder.

The MT 1281 MW length gauge from HEIDENHAIN’s METRO range now enables a test object to be measured tactilely with minimum risk from deformation or damage. This is due to the unusually low measuring force of between 0.01 N and 0.07 N manifested by the length gauge over its complete 12 mm measuring path.

The ND 287 evaluation unit is suitable as a subsequent electronics unit for stand-alone measuring stations. When combined with the METRO series, a measuring step of 1 nm is possible. It also offers many possibilities for capturing and classifying measurement series as well as creating histograms. The ND 287 thus makes it easier to evaluate the manufacturing process.