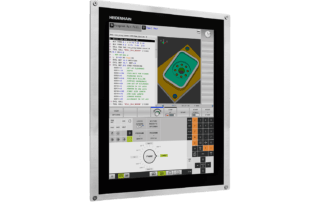

TNC7: the new level in CNC control

- For milling machines, milling-turning machines and machining centers

- Up to 24 control loops

- 5-axis and HSC machining

- Grinding, hobbing and gear cutting

- Future-proof user interface

- Task-focused multi-touch operation

- Intuitive machine setup with smart probing functions

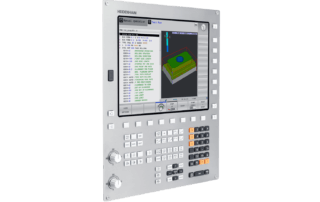

TNC 640: high all-round productivity

- For milling machines, milling-turning machines, and machining centers

- Up to 24 control loops

- 5-axis and HSC machining

- Hobbing, gear machining, and grinding operations

- Multi-touch screen

TNC 620: more efficient milling

- For milling machines and machining centers

- Up to 8 control loops

- 5-axis machining

- Multi-touch screen

TNC 320: smart modernization

- For milling and drilling machines

- Up to 6 control loops

- Tilted machining with 3+2 axes

- Analog outputs for retrofits

TNC 128: convenient and versatile

- For milling and drilling machines

- Straight-cut control for machines with a central motor

- Up to 6 control loops

- Analog outputs for retrofits

CNC PILOT 640: uncompromising turning

- For vertical and horizontal turning machines and vertical turning and boring mills

- Up to 24 control loops

- Main spindle and counter spindle, controlled spindle, Y axis, and B axis

- Multi-touch screen

MANUALplus 620: convenient operation

- For turning machines and cycle-controlled turning machines

- Up to 10 control loops Main and counter spindle, controlled spindle, Y axis, and B axisMulti-touch screen

Programming stations

- Demo version and full version

- Network licenses for up to 20 stations

- For milling and turning controls

Accessories

- Handwheels

- Camera systems

Drive systems

- Synchronous motors

- Asychronous motors

- Inverter systems