Did you know that HEIDENHAIN offers point-to-point controls for retrofit applications?

![]() A Michigan machine rebuilder is doing interesting retrofits on old mills using HEIDENHAIN TNCs and scales, enabling them to keep both the mill’s manual features and adding the advanced functions of a control. Advanced Machine Technologies, LLC (AMT) in Owosso, MI has been doing machine retrofits with HEIDENHAIN controls since 1998, and has, for example, recently completed retrofitting a 1974 Devlieg boring mill with a TNC 128 in a unique way.

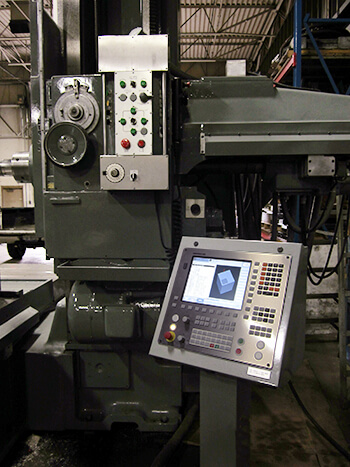

A Michigan machine rebuilder is doing interesting retrofits on old mills using HEIDENHAIN TNCs and scales, enabling them to keep both the mill’s manual features and adding the advanced functions of a control. Advanced Machine Technologies, LLC (AMT) in Owosso, MI has been doing machine retrofits with HEIDENHAIN controls since 1998, and has, for example, recently completed retrofitting a 1974 Devlieg boring mill with a TNC 128 in a unique way.

“This machine is a point-to-point mill that came to us in non-running condition with an outdated Anilam control,” explained Lee Horton, owner of AMT. “To update it, we had some mechanical work done, and totally rewired it, put in new motor drive, HEIDENHAIN scales and TNC control. It now is ready to work.

“This particular machine is unique in that normally mills would have a central drive with X and Y axes. Here, we wanted to make use of the Pocket Cycle and Drilling Cycles available on the TNC 128 control, so we opted to put a servo motor on the Z-axis also,” added Horton. “So it actually has two servo motors on it.” Now this old mill has dual function capabilities.

HEIDENHAIN’s TNC 128 is an affordable compact but versatile straight-cut control for three servo axes and servo spindle. A further servo axis is an option. Thanks to its simple operation and scope of features, it is especially well suited for use on universal milling, drilling and boring mills for a variety of applications. These applications include series and single-part production, machine building, prototypes and pilot plants, repair departments, and training and education facilities.

Horton emphasized that this TNC 128 can easily be adapted to all kinds and brands of manual machines that have never had a CNC control, making this an especially accommodating retrofit.

Horton emphasized that this TNC 128 can easily be adapted to all kinds and brands of manual machines that have never had a CNC control, making this an especially accommodating retrofit.

“We chose the HEIDENHAIN TNC 128 control for the retrofit of this old mill because it is the only one I know of that is a true point-to-point control,” added Horton. “It really is kind of a niche control. And its workshop-oriented programming makes it easy to use.

“By using this control, it allows us to give our machine retrofit customers a machine tool control without putting new ball screws on their machine that you would normally have to do with a contouring control, saving all time and money. It is very robust and durable, and does the job well that it is intended to do.”