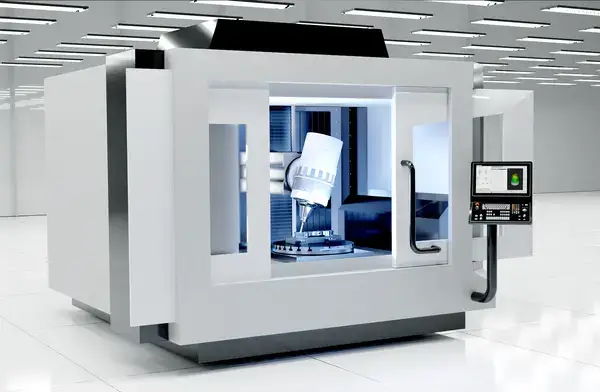

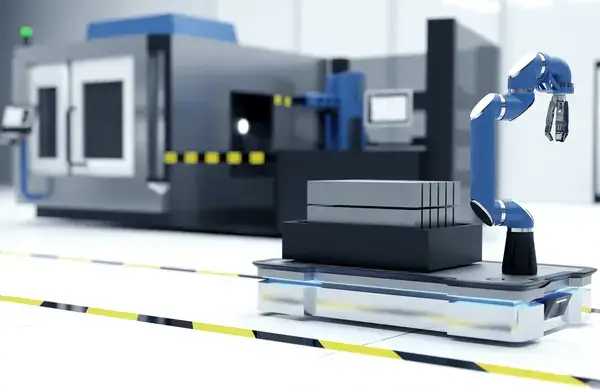

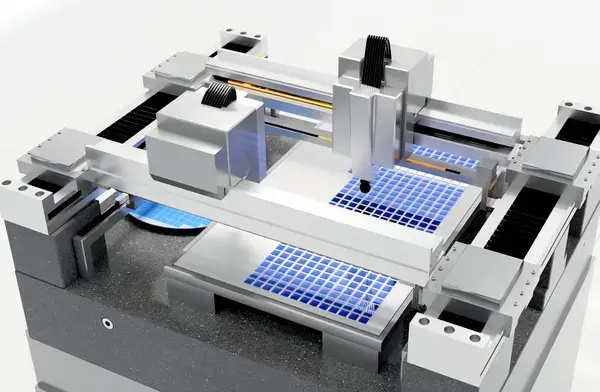

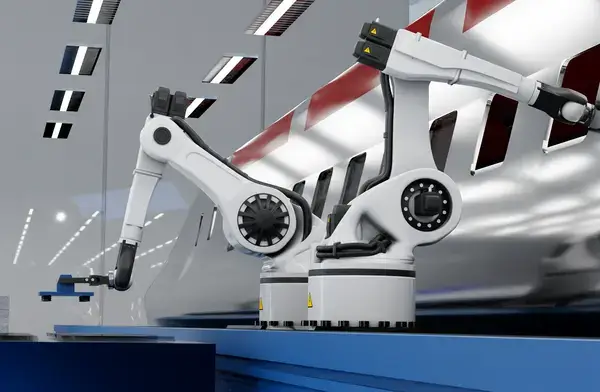

HEIDENHAIN solutions for your demanding applications

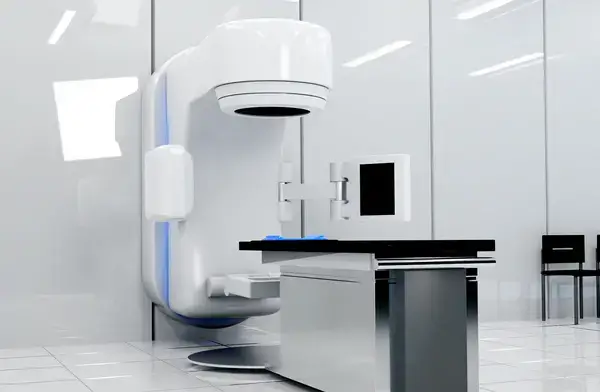

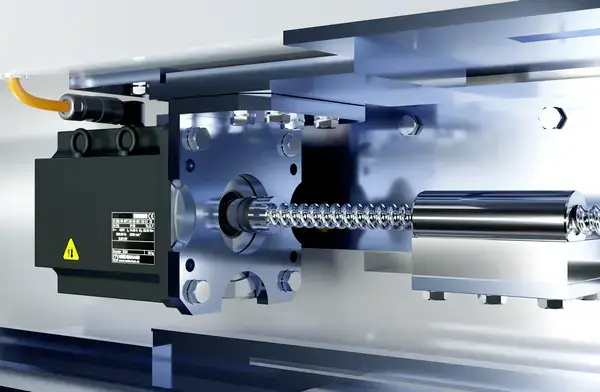

Leading in measurement, control, and drive system technology, HEIDENHAIN, together with AMO, ETEL, IMT, LTN, NUMERIK JENA, RENCO, and RSF, provides products that enable technological advances in the most innovative global industries: machine tools, automation, semiconductors, electronics, metrology, robotics, drive systems, medical technology, elevators, printing machines, structural health monitoring, and telescopes. The unyielding development of ever greater accuracy, dynamic performance, and process reliability in our products directly improves the performance and efficiency of your machines, automation systems, and processes.

Come discover the solutions we offer for your industry and how they can optimize your applications.

User portal

Strong brands for your applications

Sign up for our e-newsletter

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.